Petrochemicals are a specific set of organic chemical compounds that are mainly derived from oil & gas, via hydrocarbon cracking and chemical processing. Petrochemical processing plants are located close to (or integrated within) oil refineries, to take advantage of feedstocks, which are typically ethylene, propylene, methanol, hydrogen and aromatic hydrocarbons. Petrochemical feedstocks are used to generate thousands of polymeric chemicals for industrial and consumer use.

Petrochemical Pumps move the precursor materials that are used in the manufacturing process. For decades, Sundyne has designed petrochemical pumps that meet exacting API, ISO and ASME standards for safety, reliability and efficiency.

Olefins are a good example of Petrochemical production.

Olefins such as Ethylene and Propylene are the chemical building blocks used to make plastics, detergents and adhesives. Other Olefins like Butadiene are used to make synthetic rubber. The chemical engineering process used to makes plastics & rubber involves extreme temperatures (over 1500 ⁰F) and high pressures (over 1000 psi).

Aromatics are another example of petrochemicals found in products that people use every day. Aromatic compounds are derivatives of benzene – which is a hydrocarbon that’s common in petroleum and its distillates. Aromatics are extracted during the refining of oil. They’re used to make styrene, polyester and nylon.

What are 4 types of Petrochemical Pumps used to make Olefins and Aromatics?

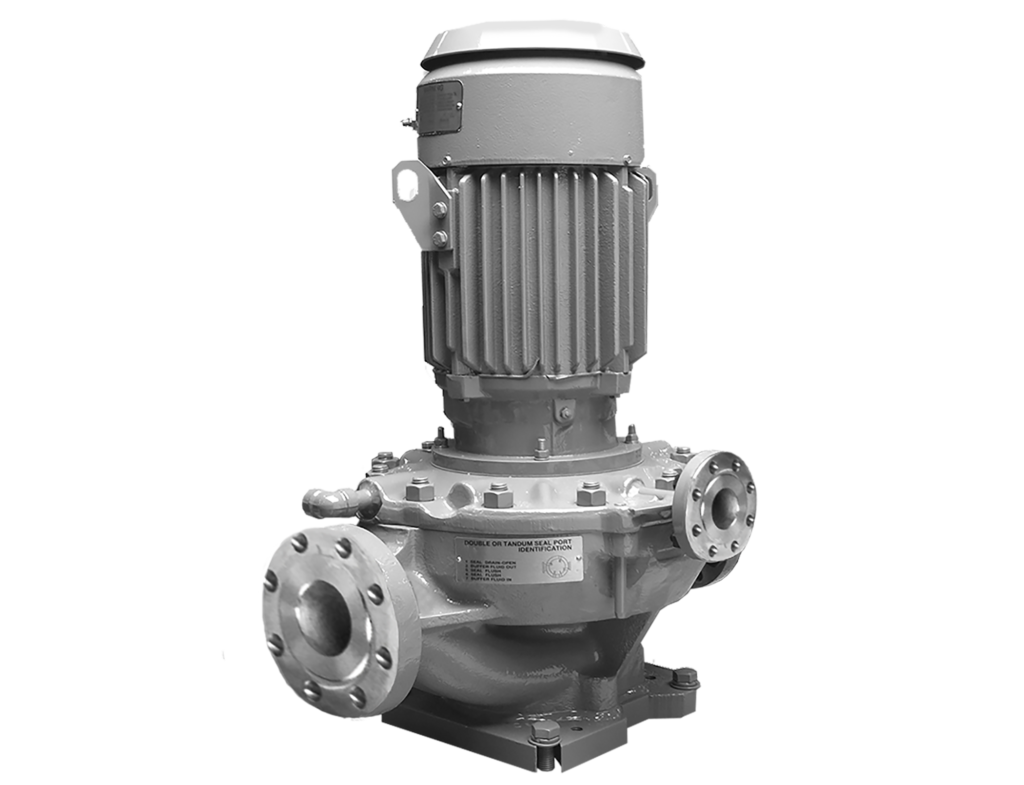

Sundyne Direct Drive Pumps:

Sundyne API 610, direct drive family of pumps are vertical inline, single stage, overhung pumps that are either a close coupled design (OH5) or features a separate bearing bracket (OH3) with a flexible shaft coupling to accommodate multiple motor options.

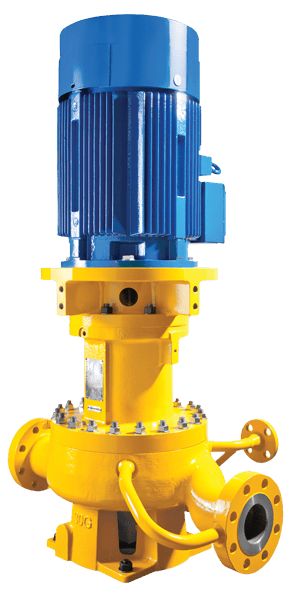

Sundyne Integrally Geared Driven Pumps:

Sundyne API 610, OH6 Integrally Geared Pumps are engineered for critical high-head, low-flow, heavy-duty services. Their unique design offers the ability to optimize efficiency, curve shape, NPSH, runout horsepower and radial loading to provide economical, reliable operation through various combinations of impeller, diffuser, and inducer geometry.

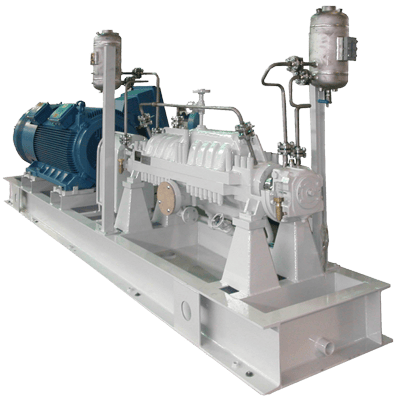

Marelli Heavy Duty API 610 Process Pumps

Highly reliable Marelli multi-stage pumps are capable of reaching massive flow rates and pressures. They are engineered to run continuously for years with rugged and low vibration balanced rotor designs. Marelli pumps meet API 610, BB1, BB2, BB3, VS1, VS2, VS4, VS6 and ISO 13709 standard requirements for overhung, between-bearings and vertically-suspended centrifugal pumps.

HMD/Kontro Sealless Magnetic Drive Pumps:

HMD/Kontro sealless designs are an alternative to traditional sealed pumps. Sealless magnetic drive pumps present no risk of emissions or leaks, which can harm productivity, personnel and the environment. Built to API 685 OH2, OH4 standards, these pumps are safe and low maintenance for petrochemical applications.

Sundyne’s experts design and manufacture pumps & compressors specifically suited for the petrochemical industry, because they meet exacting API, ISO and ASME standards for safety, reliability and efficiency.

To learn more about the unique flows & pressures, as well as the materials of construction used to manufacturer these pumps, click here.