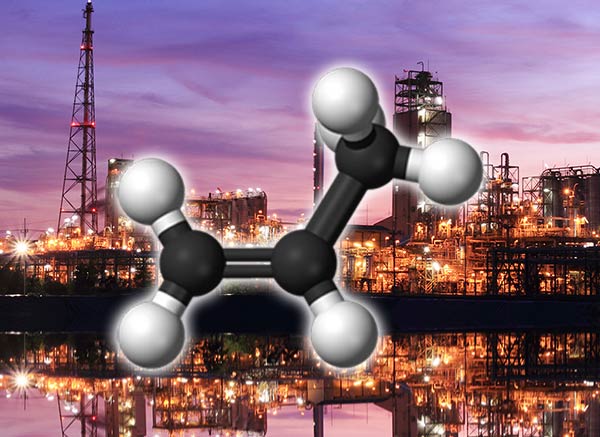

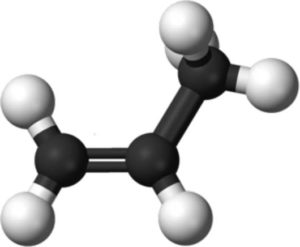

Polypropylene material is commonly used for the manufacturing of automotive components, profiles, fashion apparel, and healthcare devices. Polypropylene is a thermoplastic resin made from the polymerization of propylene. In the production of polypropylene, propylene monomer is subjected to heat and pressure in the presence of a catalyst system. Polymerization conditions, such as temperature, pressure and reactant concentrations, are set by the polymer grade to be produced.

Sundyne API 610, OH6 integrally geared LMV pumps play a critical role in the feeding of propylene into the polymerization process. Reliability is of the utmost importance to guarantee production up time. The propylene feed service requires low flow and high head. Sundyne LMV pumps deliver these flow and head conditions with a single Barske impeller running at high speed. Multistage performance is thus achieved in a simple single stage pump with a limited number of parts. Impeller and diffuser are customized to match the pump Best Efficiency Point to the customer conditions, resulting in the highest efficiency available in the market. An inducer is installed at the pump suction to achieve the low NPSH required for the propylene feed service. Low flow high head LMV pumps can be easily re-rated, if the process conditions change over time, by changing the combination of impeller, diffuser, speed and inducer geometry. The vertical inline configuration of the LMV pump makes for a compact design with minimal footprint and reduced foundation costs.

For more information on Sundyne’s Low Flow High Head Pumps, click here.