The Ultra-Low NPSHr Sundyne API 610 OH3, API 682, ISO 13709, ASME Certified Direct Drive Pump

Sundyne engineers have decades of impeller and inducer design experience. They leveraged that experience and analysis to develop a heavy duty vertical inline centrifugal pump with NPSHr performance that is unparalleled in oil and gas production, midstream and hydrocarbon processing industries. The LMV-803Lr is capable of running ultra-low NPSHr <10 ft (3 m) up and down the curve without losing performance.

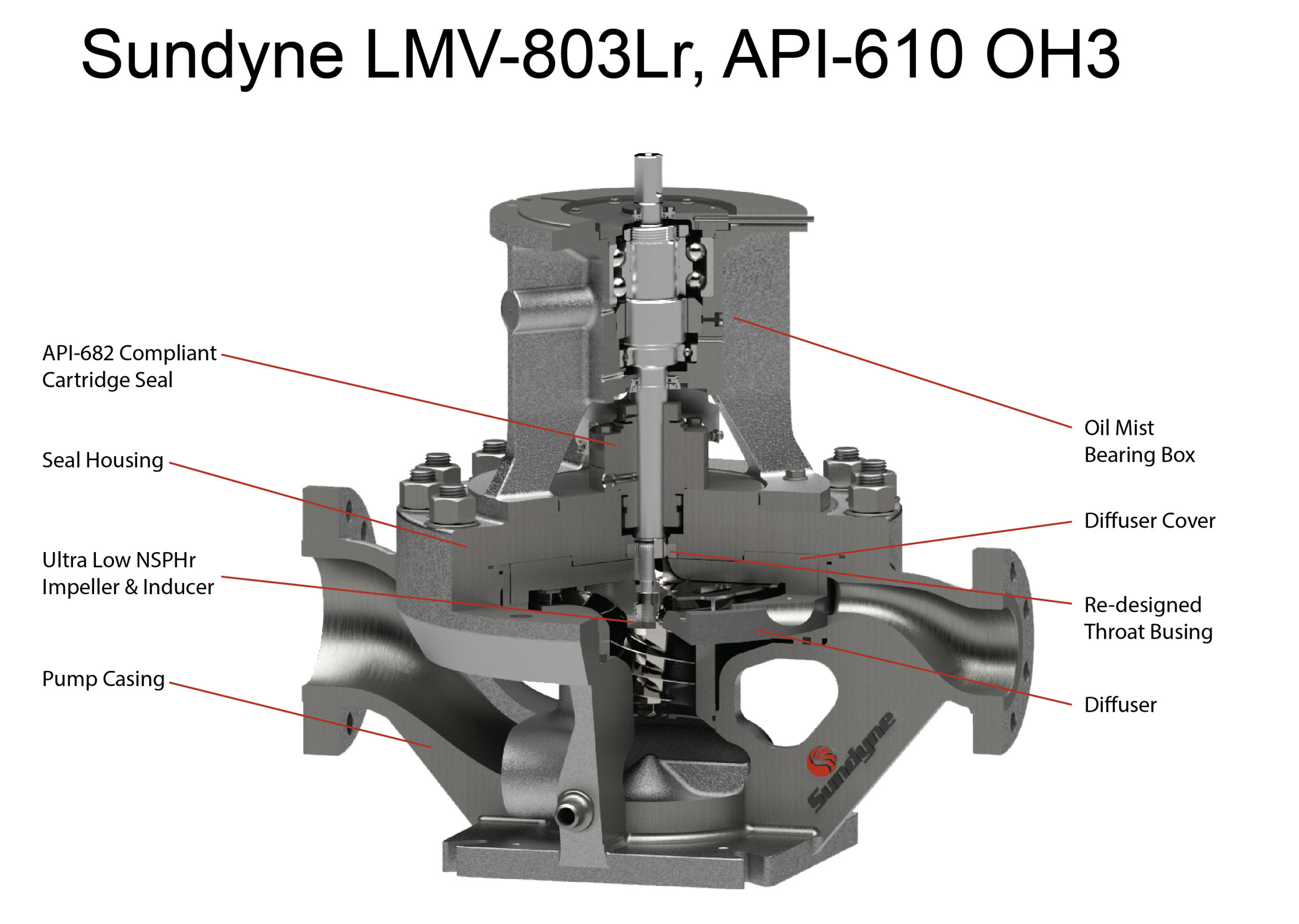

The LMV-803Lr is Sundyne’s most robust direct drive pump to date. A rugged 6×4 casing allows for higher pressures and higher flows. The pump features new inducer technology and a backswept impeller that eliminates low-inlet pressure cavitation.

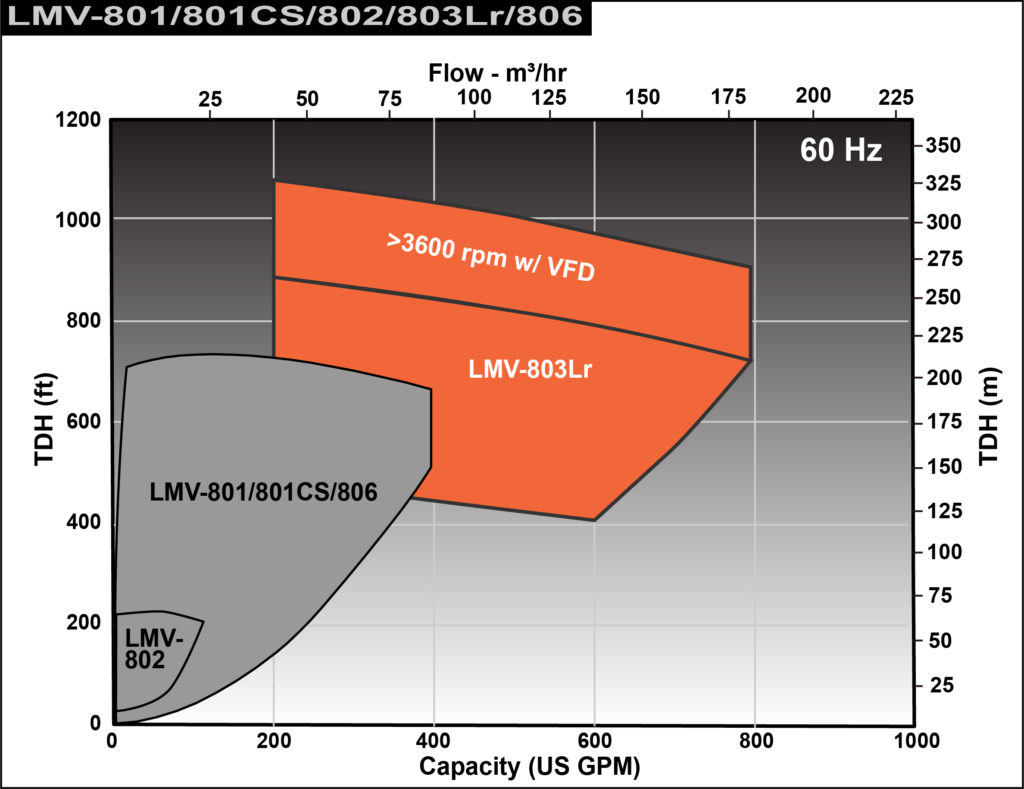

- Flows to 800 gpm (182 m³/hr)

- Heads to 1,030 ft (314 m)

- Suction Pressure 400 psi (28 bar)

- Temperature Range -200 to 400°F (-129 to 204°C)

LOWER INSTALLED COST

Because the LMV-803Lr has such a low NPSHr rating, it may be installed at grade level eliminating the need of a sump pit. This also greatly reduces the required skirt height of an elevated tower significantly reducing typical installed costs.

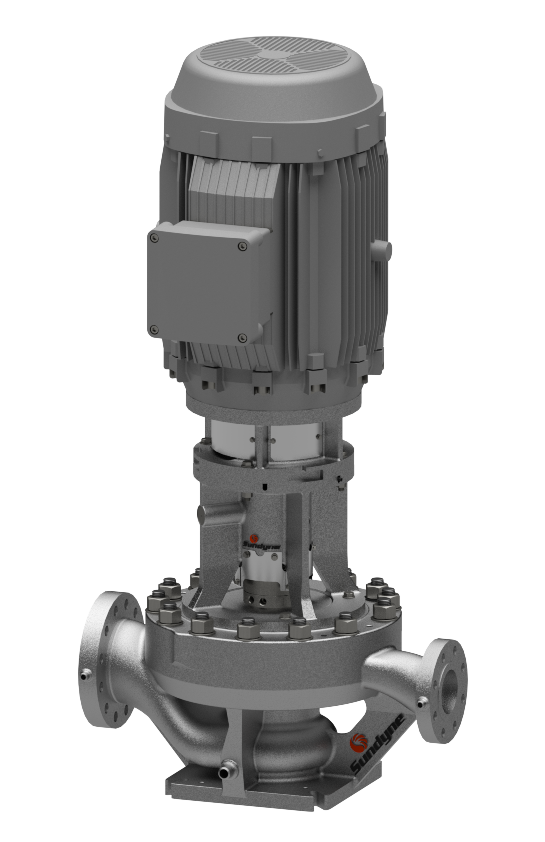

In addition, the vertical configuration of the direct drive line of Sundyne pumps are specifically designed to save valuable space in refineries, NGL production, petrochemical and chemical plants.

APPLICATIONS

- Bubble point applications (Anes/Enes)

- Feed pumps

- Fractionation pumps

- Booster pumps

- Bottoms pumps

- Liquefaction

- Wash water pumps

- Reflux pumps

- Condensate pumps

Proven to be reliable, safe, compact and efficient, Sundyne LMV 803Lr pumps provide a number of operational benefits:

- Ultra-low NPSHr, <10 ft. (3m) eliminates the need and expense of pump installation in a pit

- Ultra-low NPSHr significantly reduces the required skirt height of elevated towers

- Single stage, vertical in-line overhung pump compliant with ISO 13709/API 610 OH3/ASME design

- Enhanced throat bushing improves seal performance for light hydrocarbon applications

- Oil mist bearing box design

- Updated cryogenic design for NGL recovery, ethane, and LNG production & storage

- Can be installed at grade level greatly simplifying maintenance compared to BB & VS pumps

- Smaller hydraulic package meets a wider range of process parameters

- Saves space-25% smaller footprint of competing horizontal pumps

- API 682 cartridge seal

- Continuous operation for 5 years with no overhaul

- Proven inducer technology and backswept impeller eliminates low-inlet pressure cavitation.

US 60 Hz

- Heads to 1,030 ft

- Flows to 800 gpm

- Minimum NPSH <10 ft

- Standards API 610 OH3, ISO 13079, ASME

- Maximum Motor Power 400 HP

- Temperature Range -200 to 400°F

- Maximum Allowable Working Pressure 1,000 psig

- Maximum Suction Pressure 400 psig

- Maximum Viscosity 750 cP

- Solids Range 0.015″

- Mounting Configuration Vertical

- Seal Configurations Single, Double, Tandem-API 682 Cartridge

- Available Inducer Standard

- Available Flanges 600# ANSI RF

- Suction and Discharge Size 6″ x 4″

- API Plan 11, 13, 14, 21, 31, 41, 52, 53, 54

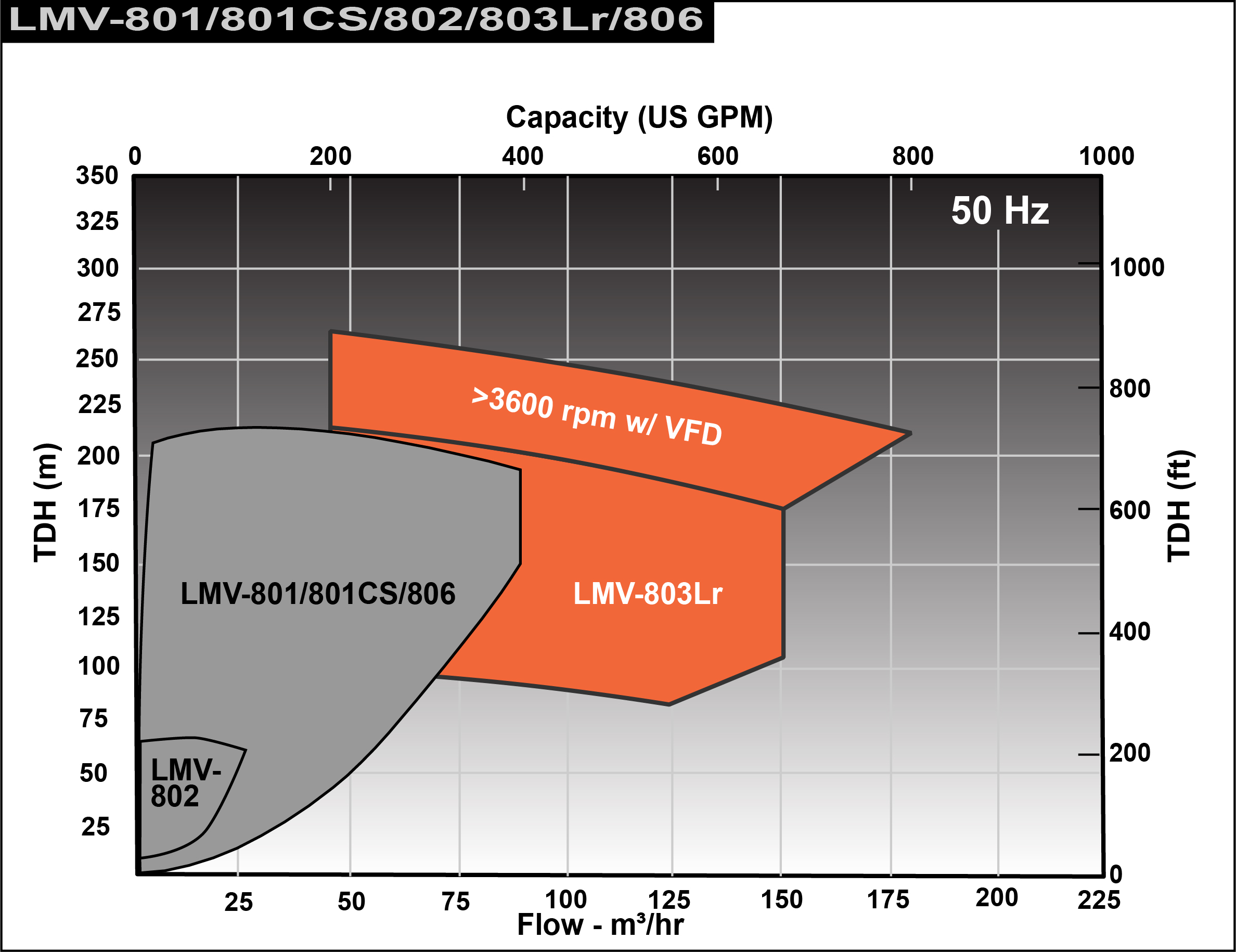

Metric 50 Hz

- Heads to 314 m

- Flows to 182 m3/hr

- Minimum NSPH <3 m

- Standards API 610 OH3, ISO 13709, ASME

- Maximum Motor Power 298 kW

- Temperature Range -129 to 204°C

- Maximum Allowable Working Pressure 69 bar

- Maximum Suction Pressure 28 bar

- Maximum Viscosity 750 cP

- Solids Range 400 microns

- Mounting Configuration Vertical

- Seal Configurations Single, Double, Tandem-API 682 Cartridge

- Available Inducer Standard

- Available Flanges 600# ANSI RF

- Suction and Discharge Size 6″ x 4″

- API Plans 11, 13, 14, 21, 31, 41, 52, 53, 54

| Part Name | Standard Build | Material Name |

| Pump Case | DH | 316L Stainless Steel |

| Seal Housing | DB | 316 Stainless Steel |

| Diffuser | DB | 316 Stainless Steel |

| Diffuser Cover | DB | 316 Stainless Steel |

| Impeller | DB | 316 Stainless Steel |

| Inducer | DB | 316 Stainless Steel |

| Inducer Stud | BB | 4140 Steel |

| Tab Washer | DB | 316 Stainless Steel |

| Shims | DJ | 300 Series Austenitic SS |

| Shaft | DD | 17-4 PH Stainless Steel |

| Pump Case Studs | BB | 4140 Steel |

| Throttle Bushing | RA | Carbon |

| Cartridge Seal | DB | 316 Stainless Steel |

| Seal Guard | GL | Aluminum Alloy |

| Bearing Box Housing | AA | Low/Medium Carbon Steel |

| Bearing Box Cover | AA | Low/Medium Carbon Steel |

| Coupling Housing | GC | Aluminum Alloy |

| Coupling Guard | GC | Aluminum Alloy |

Sundyne LMV 803 Lr Data Sheet US – PDF

Sundyne LMV 803Lr Data Sheet A4 – PDF

Sundyne LMV 803Lr Cutaway Poster – PDF

Sundyne Direct Drive API OH3, OH5 Centrifugal Pumps Brochure US – PDF

Sundyne Direct Drive API OH3 and OH5 Centrifugal Pumps Brochure A4 – PDF

Sundyne The Vertical Experts Brochure US – PDF