``If that compressor goes down, the plant goes down. That's why we commissioned a Sundyne.``

Reliable Process Gas Compressors for Midstream, Downstream and Power Generation

In 1965, Sundyne designed and built the first integrally geared vertical compressor for Union Carbide. The space saving design was based on the very successful Sundyne LMV integrally geared pump technology. Since then, more than 50 years of experience and innovation has come from thousands of deployments in oil and gas upstream, midstream and downstream plants in some of the world’s most demanding environments.

Today, the Sundyne compressor line features single- and multi-stage centrifugal designs for API 617 and fit-for-purpose applications including fuel gas boost in power generation. Each model is custom built to provide pulsation- and vibration-free operation, and to deliver oil-free process gas with zero emissions.

NACE compliant Sundyne Compressors handle the most difficult gas processing operations. Each unit is engineered in accordance with industry standards, and is designed to run continuously for 5 to 7 years without the need for costly maintenance or over-hauls.

Sundyne gas compressors provide the performance envelope, the feature set, the reliability ratings and the uncompromising efficiency needed to address the Best Efficiency Point (BEP) for any application.

World Renowned for Handling Difficult Applications

OIL & GAS PRODUCTION & PROCESSING

Flash Gas

Gas Gathering

NATURAL GAS PROCESSING

Mole Sieve Regeneration

Off Gas Compression

Natural Gas Boosting

Nitrogen Circulation

Demethanizer

POWER GENERATION

Fuel Gas Boost

Carbon Capture Recycle Compression

Syngas Recycle & Flash Gas

HYDROCARBON PROCESSING

Hydrogen Recycle

Lift Gas

H2S Wet Gas

Stripper Overhead

Gas Boost

Recycle Gas (PP, PE, H2)

Reactor Feed & Regeneration

Recirculation Gas

Ethylene Feed & Recycle

HC Boost / Overhead

Butane

Clean Fuels

Desulfurization

Nitrogen Startup

CHEMICAL PROCESSING

Ammonia

Hydrogen Recycle

Waste Gas

Refrigeration

Purge Gas

Flue Gas

CO2 / CO

Nitrogen

Vinyl Chloride

Chlorine

LMC-Vertical Line Mounted Integrally Geared Compressors

- Flows to 2,500 acfm (4,150 m³/hr)

- Maximum Pressure 2,300 psi (160 bar)

- Maximum Speed 34,200 rpm

- Max Motor Size 550 HP (410 kW)

- Temperature Range -200 to +500°F (-130 to +260°C)

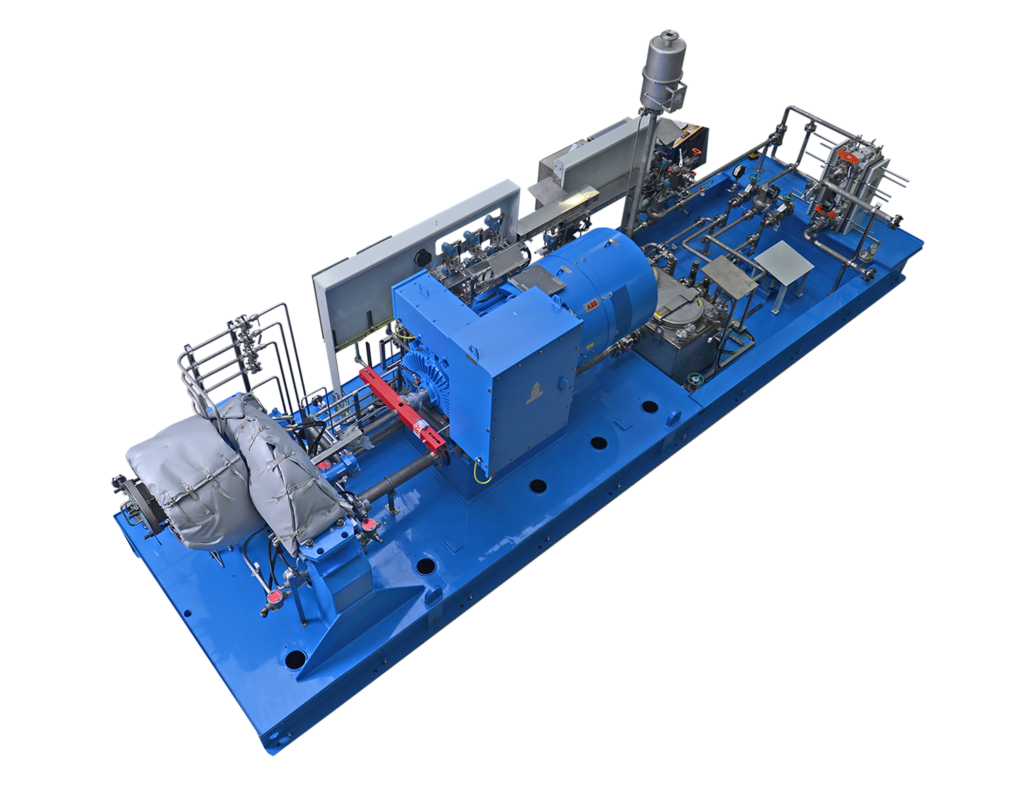

BMC Integrally Geared Centrifugal Process Gas Compressors

- Flows to 2,500 acfm (4,150 m³/hr)

- Maximum Pressure 2,300 psi (160 bar)

- Maximum Speed 34,200 rpm

- Maximum Power 550 HP (410 kW)

- Temperature Range -200 to +500°F (-130 to +260°C)

LF 2X80 Integrally Geared Multistage Compressor

- Flows to 6,000 acfm (10,200 am³/hr)

- Max Working Pressure 1,440 psi (100 bar)

- Max Speed 32,000 rpm (60 Hz), 32,000 rpm (50 Hz)

- Max Motor Size 800 HP, 596 kW

- Temperature Range -200 to 500°F (-130 to 260°C)

LF 2000 Integrally Geared Multistage Compressor

- Flows to 10,000 acfm (17,000 am³/hr)

- Max Working Pressure 5,000 psi (350 bar)

- Max Speed 42,000 rpm (60 Hz), 42,000 rpm (50 Hz)

- Max Motor Size 10,000 HP, 7,500 kW

- Temperature Range -200 to 500°F (-130 to 260°C)