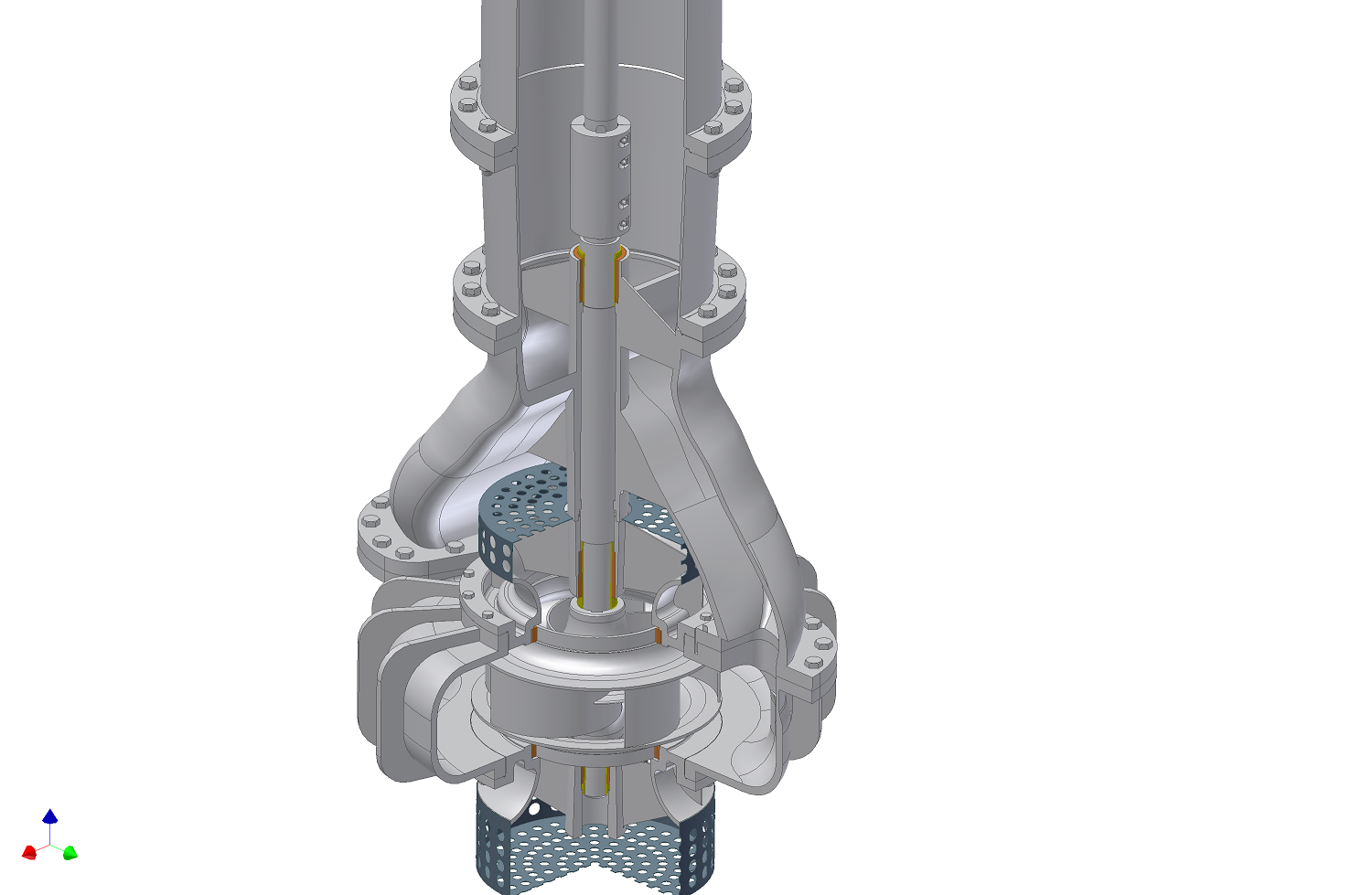

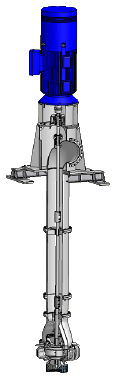

The FQ API-610 11th Edition VS2 vertical mounted, double suction impeller centrifugal pumps are highly reliable and ideal for sump applications. Ideal for refining cooling towers, raw water intake, water transfer, irrigation and development.

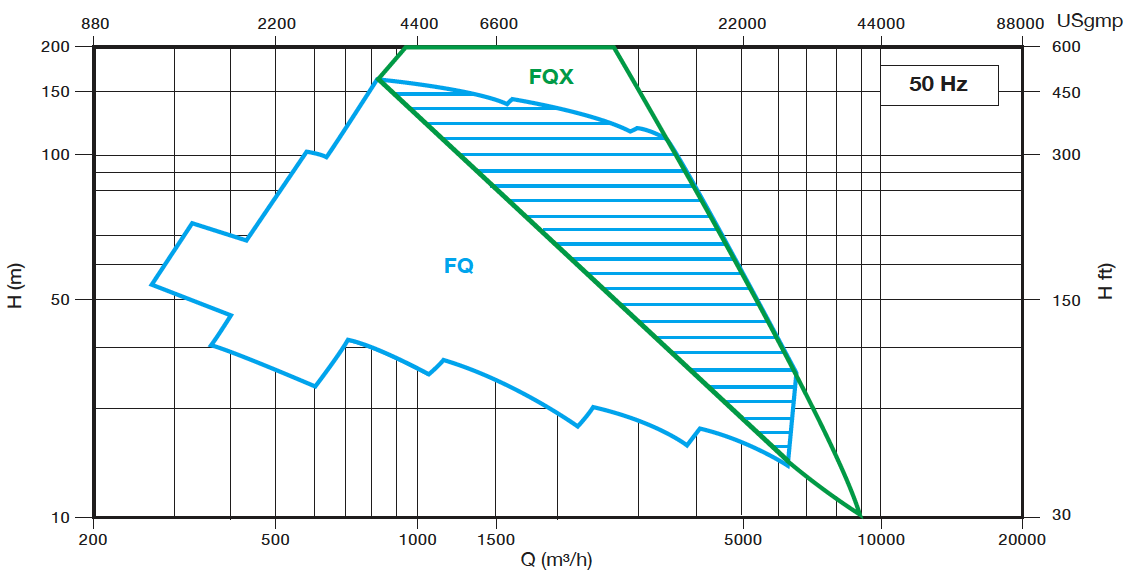

The FQ sub-family comprises all one stage pumps while the FQX sub-family comprises pumps with several stages, one of them as FQ sub-family inside the bulb volute, and all other stages incorporation alongside the suspension column itself.

- Flows to 39,600 gpm (10,000 m³/hr)

- Heads to 490 ft (150 m)

- Maximum Case Working Pressure 218 psi (15 bar)

- Temperature Range -22 to 482°F (-30 to 250°C)

APPLICATIONS

- Sea water intake

- Desalination plants

- Water reservoir

- Cooling towers

- Industrial applications

- Petrochemical

- Refineries

- Tank farms for Oil & Gas

- API tanks

- Waste water treatment plants

Marelli has more than 50 years of experience in centrifugal pump design, development, manufacturing and service around the world. Vertical suspended centrifugal pumps are a core product family developed under API610/ISO 13709, latest edition standards.

Double suction vertical suspended centrifugal pumps FQ/FQX, improve the hydro-mechanical performances compare to the traditional vertical pumps, saving costs in their preventive maintenance and overhaul, to help the hydraulic management in medium and big flow applications.

US 60 Hz

- Heads to 490 ft

- Flows to 39,600 gpm

- Standards API 610 VS2

- Maximum Motor Power 2,000 HP

- Temperature Range -22 to 482°F

- Maximum Case Working Pressure 218 psi

- Maximum Suction Pressure Flooded

- Differential Head 492 ft

- Maximum Viscosity Consult Factory

- Mounting Configuration Submersible Vertical

- Seal Configurations API 682

Metric 50 Hz

- Heads to 150 m

- Flows to 10,000 m3/hr

- Standards ISO 13709

- Maximum Motor Power 1500 kW

- Temperature Range -22 to 250°C

- Maximum Case Working Pressure 15 bar

- Maximum Suction Pressure Flooded

- Differential Head 150 m

- Maximum Viscosity Consult factory

- Mounting Configuration Submersible Vertical

- Seal Configurations API 682

| Part | S1 | S5 | S6 | S8 | C6 | A8 | D1 |

| Pressure Casing | Carbon Steel (A216 WCB) | 12% CHR | 316 AUS | Duplex | |||

| Impeller | Cast Iron | Carbon Steel | 12% CHR | 316 AUS | 12% CHR | 316 AUS | Duplex |

| Wear Rings | Cast Iron | 12% CHR Hardened | Hard-faced 316 AUS | 12% CHR Hardened | Hard-faced 316 AUS | Hard-faced Duplex | |

| Shaft | Carbon Steel | AISI 4140 | 316 AUS | 12% CHR | 316 AUS | Duplex | |

| Bearing Housing | Carbon Steel (A216 WCB) | ||||||

| Base Gasket | AUS, Spiral Wound | 316 AUS Spiral Wound | AUS, Spiral Wound | 316 AUS, Spiral Wound | Duplex SS Spiral Wound | ||