HMD Kontro Sealless Magnetic Drive Pumps

Since pioneering the sealless magnetic drive pump in the 1940’s, HMD Kontro have been at the forefront of the liquid handling industry providing pump products with high performance, superior reliability, increased safety and full industry compliance.

An HMD Kontro sealless pump is a conventional centrifugal pump without mechanical seals. Using modern engineering and technologies developed over decades of experience in the handling of harsh and hazardous fluid applications, HMD Kontro pumps offer numerous benefits:

• Total fluid containment providing better environmental protection & operator safety

• No seals or seal support systems simplifying procurement, installation, operation and maintenance, reducing lifecycle costs

• World class sealless pump technology that offers the highest levels of robustness in the field, increasing Mean Time Between Failure (MTBF) and plant uptime

• Compliance to industry standards and global availability

Common HMD Kontro Pump Applications

Upstream Oil and Gas

- Offshore Oil Rigs

- FPSO’s

Hydrocarbon Processing

- Downstream Refining

- Downstream Petrochemical

Chemical Processing

- Chlor-Alkali

- Fine Chemical Production

Industrial

- Pharmaceutical manufacturing

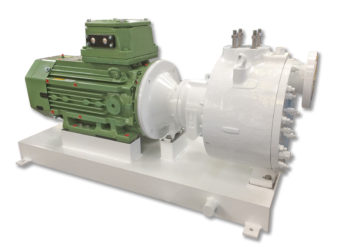

Chemical Service Pump – CSA/CSI

- Flows to 1,408 gpm (320 m³/hr)

- Heads to 490 ft (150 m)

- Design Pressure: 275 psi (18.9 bar) ASME; 232 psi (16 bar) ISO

- Temperature Range -40 to 500°F (-40 to 260°C)

General Service Pump – GSA/GSI

- Flows to 1,408 gpm (320 m³/hr)

- Heads to 490 ft (150 m)

- Design Pressure: 275 psi (18.9 bar) ASME; 232 psi (16 bar) ISO*

- Temperature Range -40 to 500°F (-40 to 260°C)

*360 psi (25 bar) & 710 psi (49 bar) designs available for selected models

General Transfer Pump – GTA/GTI

- Flows to 115 gpm (26 m³/hr)

- Heads to 125 ft (38 m)

- Design Pressure: 275 psi (18.9 bar) ASME; 232 psi (16 bar) ISO

- Temperature Range -40 to 500°F (-40 to 260°C)

High Pressure Pump – HPGS

- Flows to 317 gpm (72 m³/hr)

- Heads to 305 ft (93 m)

- Design Pressure: 2,680 psi (185 bar)

- Temperature Range -40 to 400°F (-40 to 205°C)

Self Priming Pump – SPGS

- Flows to 200 gpm (45 m³/hr)

- Heads to 170 ft (52 m)

- Design Pressure: 145 psi (10 bar)

- Temperature Range -40 to 248°F (-40 to 120°C)

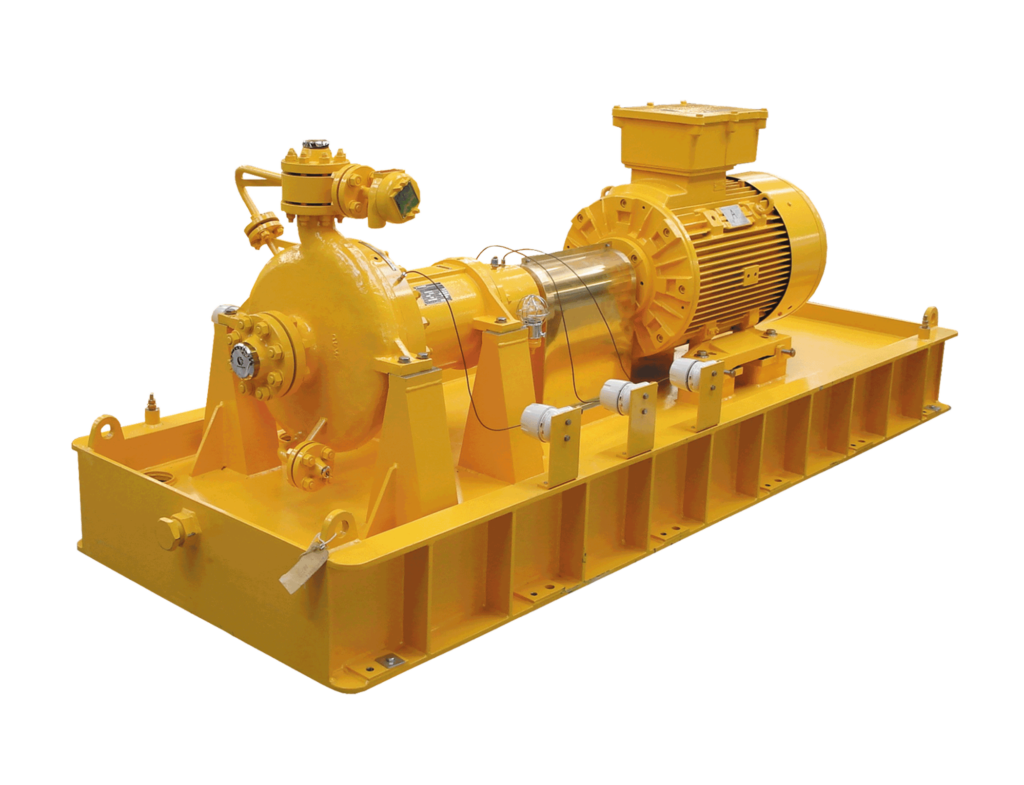

Petrochemical & Petroleum Industry API 685 Pump – GSP

- Flows to 3,084 gpm (700 m³/hr)

- Heads to 790 ft (240 m)

- Design Pressure 580 psi (40 bar)

- Temperature Range -148 to 660°F (-100 to 350°C)

Vertical API 685 Pump – GSPV

- Flows to 1,035 gpm (235 m³/hr)

- Heads to 295 ft (90m)

- Design Pressure: 580 psi (40 bar)

- Temperature Range -40 to 400°F (-40 to 205°C)

Low-Flow API 685 Pump – GSPLF

- Flows to 380 gpm (86 m³/hr)

- Heads to 720 ft (220 m)

- Design Pressure: 580 psi (40 bar)

- Temperature Range -148 to 600°F (-100 to 315°C)

Vertical Low-Flow API 685 Pump – LMV-801S

- Flows to 380 gpm (86 m³/hr)

- Heads to 720 ft (220 m)

- Design Pressure 1,450 psi (100 bar)

- Temperature Range -148 to 400°F (-100 to 205°C)

High Pressure API 685 Pump – HPGSP

- Flows to 1,275 gpm (290 m³/hr)

- Heads to 490 ft (150 m)

- Design Pressure: 2,683 psi (185 bar)*

- Temperature Range -40 to 500°F (-40 to 260°C)

*2,683 psi (185 bar) designs available for selected models