Accuracy under high-pressure for checking the density of process fluids in a high pressure pipe-line

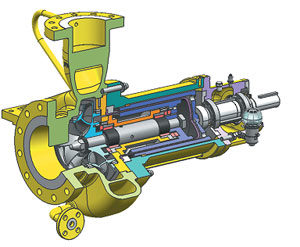

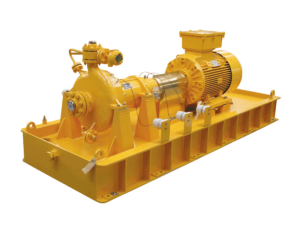

Original equipment manufacturers worldwide have discovered the benefits of the HPGS pump when checking the density of fluids passed down a high-pressure pipeline. Process engineers utilize this pump on pipeline skids to take a sample of the fluid out of the main product stream. The sample is then passed through the densitometer, which analyses the fluid, and is then returned to the main pipeline.

The HPGS sealless magnetic drive pump can withstand system pressures up to 2680 psi (185 bar).

- Sealless design for total product containment

- Ideal in petrochemical and site utilities

- Modular/lnterchangeable high efficiency wet end

- Provide maximum flow and head coverage across all product ranges

- High efficiency magnetic couplings

- Various metallic materials of construction available

- System pressures up to 2680 psi (185 bar)

- Ideal sampling unit for densitometer applications

- Flows up to 1,460 GPM (330 m³/hr)

- Heads to 685 ft (210 m)

- Temperature Range -40 to 500°F (-40 to 260°C)

HPGS sealless magnetic drive, end suction centrifugal pumps comply with specifications required by the oil, gas, petroleum and heavy chemical industries. The GSP is typically used in toxic, aggressive, hot, crystallizing and high value processes.

APPLICATIONS

Chemical Processing

- Chlor-Alkali

- Pesticides

- Insecticides

- Herbicides

- Fertilizer

Hydrocarbon Processing

- Sour water

- Sulfuric acid

- Benzene

- Xylene

- Toluene

Upstream

- Produced water

- LACT

Aquatic and Marine

- Seawater

- Caustic

Battery Manufacturing

- Sulfuric acid

- Potassium hydroxide

Biofuels

- Bio-diesel

- Ethanol

Food and Beverage

- Fragrances

Mining

- Sodium cyanide

- Sulfuric acid

- Hydrochloric acid

Pharmaceutical

- Silicon oil (Heat transfer fluid)

Pulp and Paper

- Chlorine

- Sulfuric Acid

Semiconductor Manufacturing

- Hydrofluoric acid

- Sulfuric acid

Steel Finishing, Pickling, Etching and Plating

- Hydrochloric acid

Water and Wastewater Treatment

- Sodium hypochlorite

- Sodium hydroxide

- Sulfuric acid

- Ferric Chloride

Our pumps combine cutting-edge technology with over seventy years of expertise and experience to give you complete piece of mind.

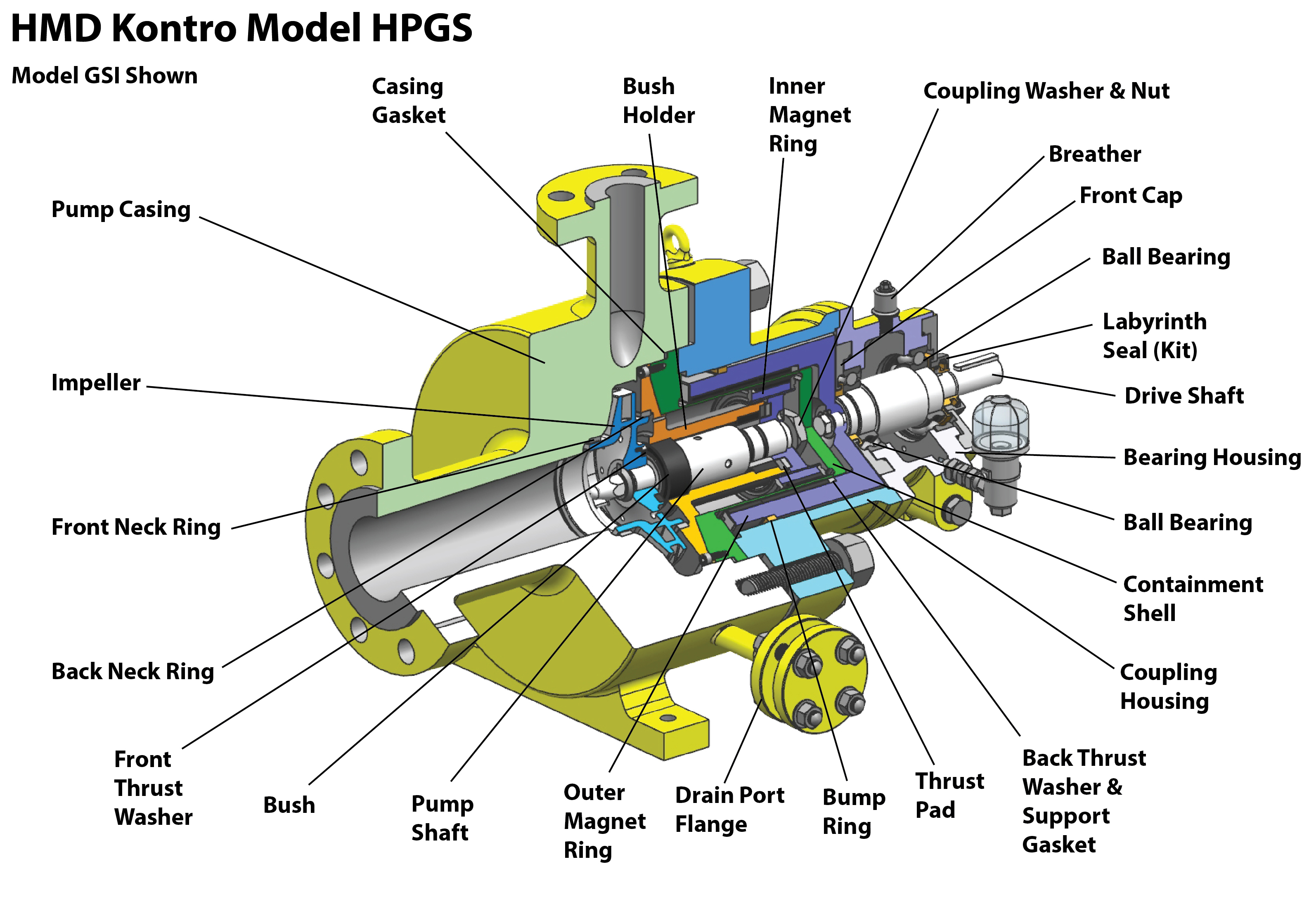

Product Security – Magnetic drive sealless pumps are the safest and most robust means for liquid transfer. By eliminating the seal, the primary opportunities for leaks associated with traditional sealed pumps are completely removed.

Efficiency – By improving performance and reducing maintenance calls, sealless magnetic drive pumps can dramatically lower downtime and lost production. In sum, this equates to maximized efficiency that can be seen on your bottom line.

Reliability – Sealless magnetic drive pumps have proven their reliability in even the most severe climate conditions, from the frozen tundra of Siberia to the deserts of the Middle East and the humid climes of Louisiana’s refineries. In fact, there are Sundyne HMD Kontro pumps that have been in operation for over 30 years and are still running today.

Safety – Sundyne HMD Kontro sealless magnetic drive pumps are manufactured to conform to international design and safety standards, including ATEX, ISO, API and ANSI requirements. Plus, with no mechanical seals to leak hazardous chemicals, these pumps offer a clear choice for process industry professionals who regularly deal with volatile or high value materials.

Cost-effective – Sealless magnetic drive pumps require less monitoring and maintenance than traditional sealed designs, equating to substantial savings over the life of the pump.

Service – Global service centers keep HMD Kontro sealless magnetic drive pumps operating with peak performance. Standard pumps and parts are available from the factory and in the field.

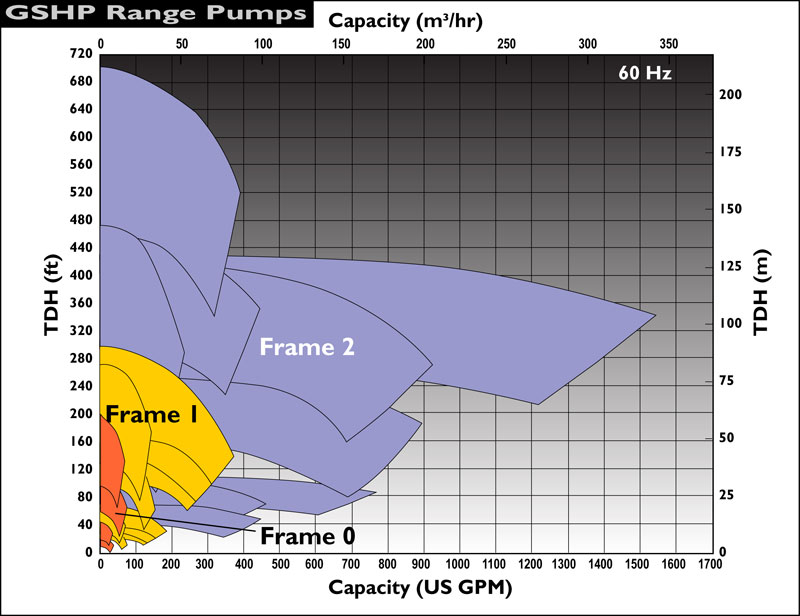

US 60 Hz

- Heads to 1,146 ft

- Flows to 3,647 gpm

- Maximum Motor Power 535 HP

- Temperature Range -40 to 660°F

- Maximum Case Working Pressure 580 psi

- Hydrotest Pressure 870 psi

- Maximum Viscosity 200 centistokes

- Solids Range Maximum of 5% w/w less than 150 microns

- Motor Details Industry standard

- Mounting Configuration Horizontal close and long coupled

- Dimensional Standards API 610 OH2, ISO 13709

- Number of Available Hydraulics 28

- Available Flanges 150#/300# RF

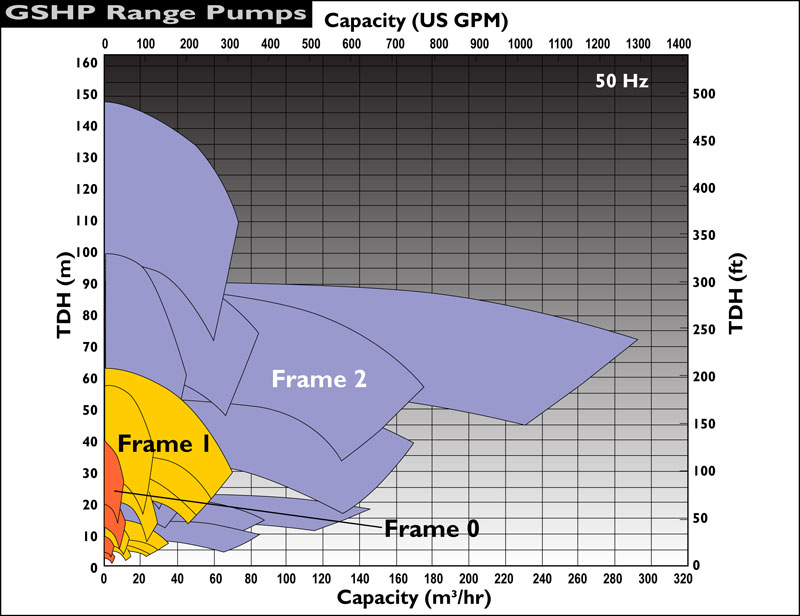

Metric 50 Hz

- Heads to 245 m

- Flows to 3,467 m3/hr

- Maximum Motor Power 400 kW

- Temperature Range -40 to 350°C

- Maximum Case Working Pressure 19.3 kg/cm2

- Hydrotest Pressure 41 kg/cm2

- Maximum Viscosity 200 centistokes

- Solids Range Maximum of 5% w/w less than 150 microns

- Motor Details Industry Standard

- Mounting Configuration Horizontal close and long coupled

- Dimensional Standards ISO 13709

- Number of available hydraulics. 28

- Available Flanges 150#/300# RF

Standard materials of construction

- A-8 and S-5 with silicon carbide internal bearings and spiral wound gaskets.

Other material options are available on request

- Duplex Stainless Steel

- Alloy 20 and Alloy C276

- Various flange options are available as standard

POWER MONITOR

Installed in the Motor Control Center (MCC), a power monitor measures the power required to operate the pump. By setting High and Low trip points, the power monitor is the perfect solution for protecting your pump from:

- Dry running

- Low flow operation

- High flow operation

- Severe cavitation

- Magnet de-coupling

New ZeroLoss Containment Shell

Reduces Power Losses in the Pump to Zero

Excellent energy savings can now be made thanks to the introduction of the ZeroLoss containment shell for larger pumps. The elimination of eddy current losses can result in up to a 20% saving in power consumption, further enhancing the benefits and green credentials of magnetic drive technology from Sundyne HMD Kontro.

The advantage increases in proportion with the magnetic coupling size and is particularly appropriate for larger pumps, making the magnetic drive option even more attractive because through life costs are reduced further. Lower powerconsumption not only results in reduced running costs but alsopotentially provides lower initial capital costs, as smaller motors can be specified.

In addition, installation costs can be reduced as lower-rated cabling may be required, and there are space-savings from the ability to use a smaller base plate for the pump and motor combination.

SECONDARY CONTROL & CONTAINMENT

HMD Kontro Sealless magnetic drive pumps are available with secondary control devices to restrict any leaks. Mechanical devices are fitted to the drive shaft assembly and are activated in the unlikely event of containment shell failure. Also, the pump coupling housing is fitted with gaskets to eliminate any leaks across the joining faces.

Solids Handling

All HMD Kontro pumps, as standard, can handle up to 5% hardsolids and 150 microns diameter. The solid size can increase by fitting a self-cleaning in line filter, to 8% solids and 250 microns.

For larger solids HMD Kontro can provide pumps with a clean flush system or filter built into the flush pipework.

HMD Kontro HPGSP Brochure US – PDF

HMD Kontro HPGSP Brochure A4 – PDF

HMD Kontro Zero Loss Containment Shroud Technical Paper – PDF

HMD Kontro Zero Loss Containment Shell Brochure A4 – PDF

HMD Kontro Zero Loss Containment Shell Technical Profile A4 – PDF

HMD Kontro Zero Loss Containment Shell Data Sheet US – Â PDF

HMD Kontro Sealed vs Sealless Pump Technical Article – PDF

HMD Kontro Sealless Pump Know How Guide US – PDF

HMD Kontro Sealless Pump Know How Guide A4 – PDF

HMD Kontro No Seal Required Technical Article – PDF

HMD Kontro Product Range Brochure US – PDF