ISO 2858/15783 ETFE-Lined Aggressive Liquids Chemical Pump

No leaks for safe processing and handling of hazardous chemicals

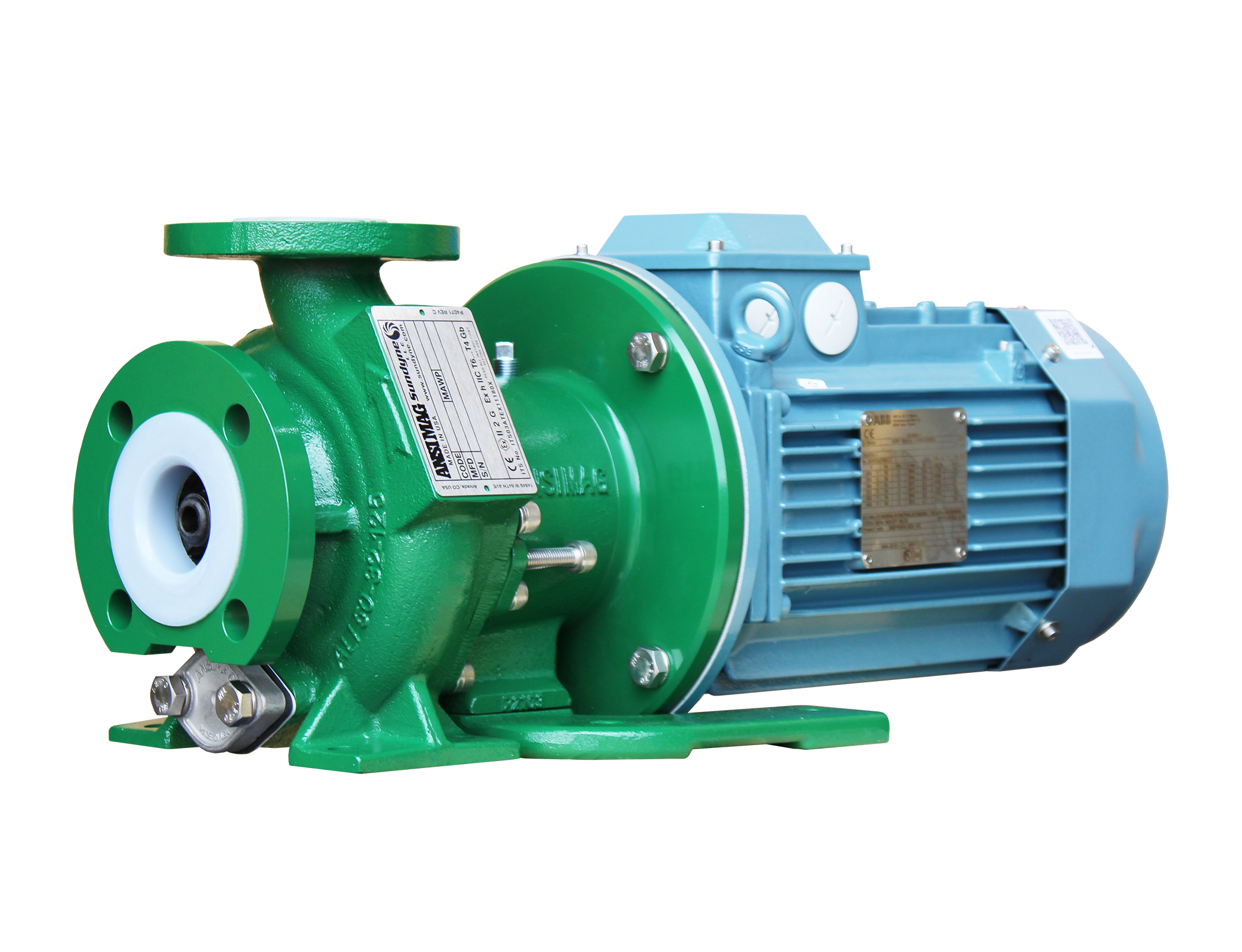

The Ansimag ALI (Aggressive Liquid ISO), ETFE lined, sealless magnetic drive centrifugal pump is ideal for most applications in the chemical, specialty chemical, steel, municipal water, wastewater and process water transfer in upstream Oil & Gas industries.

ANSIMAG sealless magnetic drive pumps are more energy-efficient than mechanically sealed pumps. An innovative rear casing generates no eddy currents thus eliminating heat generation and reducing energy costs. Because ANSIMAG pumps do not have seals – there are no leaks, no emissions and no costs related to seal maintenance.

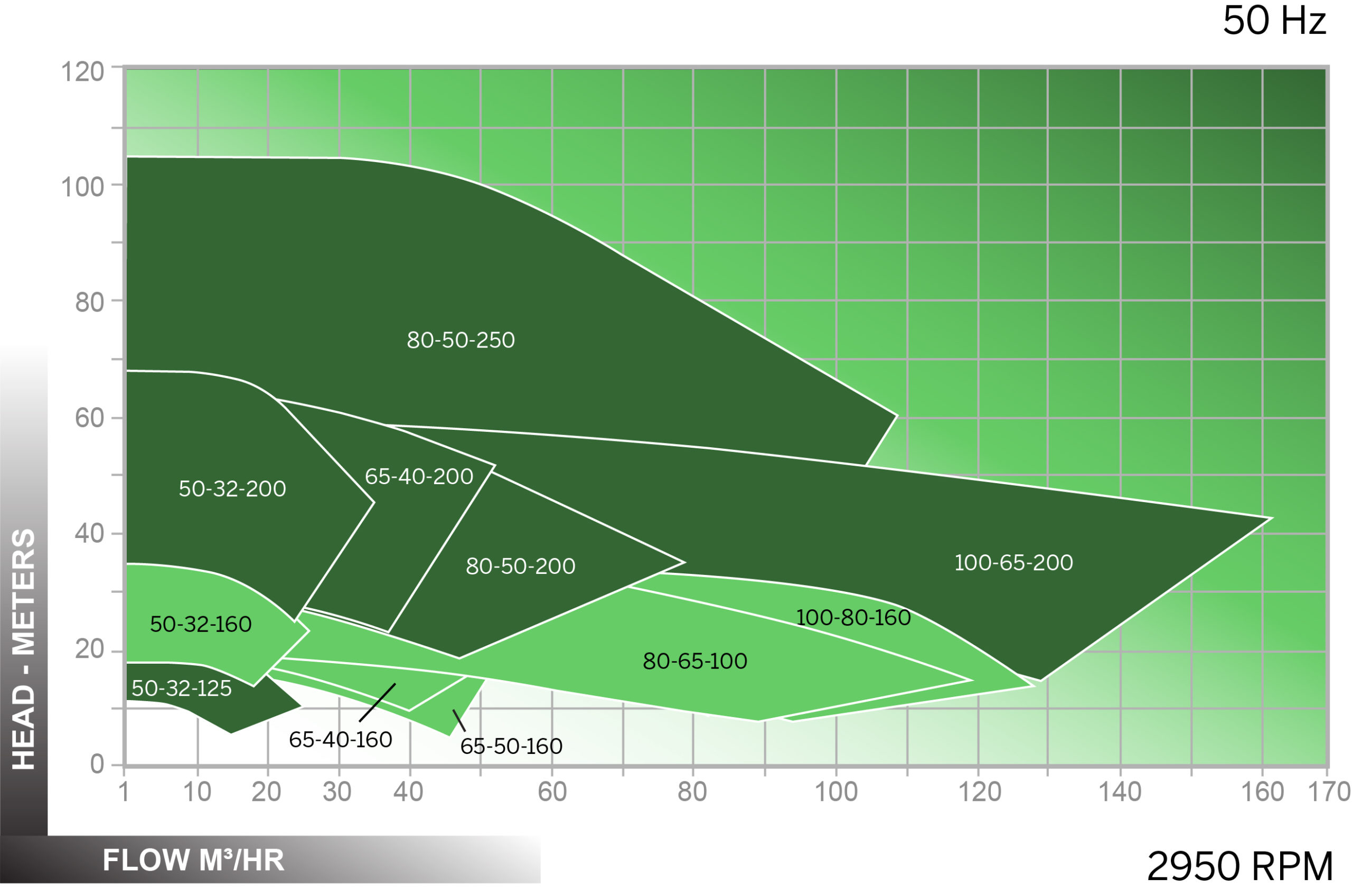

- Flows up to 150 m³/hr

- TDH up to 105 m

- Temperature Range -29 to 121°C

ANSIMAG ALI pumps provide affordable replacement options for aging ISO 2858 sized pumps, because the line covers a wide range of sizes and standard external dimensions to facilitate sealless or sealed pump replacement without changing piping or base plates.

The ANSIMAG ALI is ideal for most corrosive or acidic applications in the chemical, specialty chemical and steel industries.

Simple By Design

With only 9 wetted parts, ANSIMAG pumps are the simplest, most reliable pumps to own, operate and maintain.

APPLICATIONS

Chemical Processing

- Chlor-Alkali

- Pesticides

- Insecticides

- Herbicides

- Fertilizer

Hydrocarbon Processing

- Sour water

- Sulfuric acid

- Benzene

- Xylene

- Toluene

Upstream

- Produced water

- LACT

Aquatic and Marine

- Seawater

- Caustic

Battery Manufacturing

- Sulfuric acid

- Potassium hydroxide

Biofuels

- Bio-diesel

- Ethanol

Food and Beverage

- Fragrances

Mining

- Sodium cyanide

- Sulfuric acid

- Hydrochloric acid

Pharmaceutical

- Silicon oil (Heat transfer fluid)

Pulp and Paper

- Chlorine

- Sulfuric Acid

Semiconductor Manufacturing

- Hydrofluoric acid

- Sulfuric acid

Steel Finishing, Pickling, Etching and Plating

- Hydrochloric acid

Water and Wastewater Treatment

- Sodium hypochlorite

- Sodium hydroxide

- Sulfuric acid

- Ferric Chloride

Proven to be reliable, safe, compact and efficient, ANSIMAG sealless magnetic drive ETFE lined pumps provide a number of operational benefits:

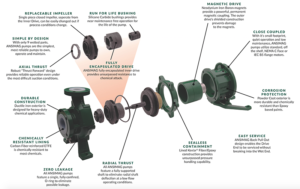

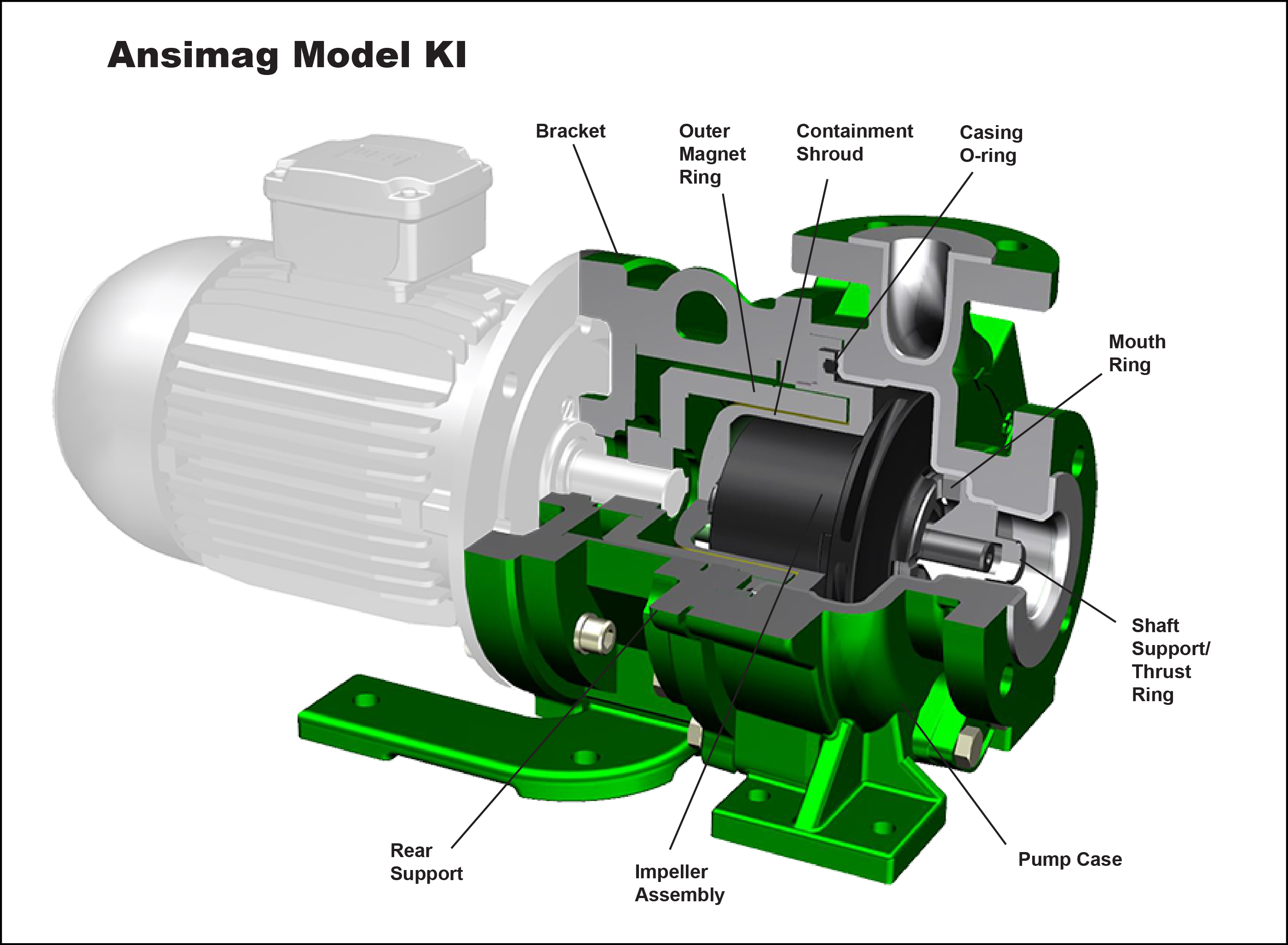

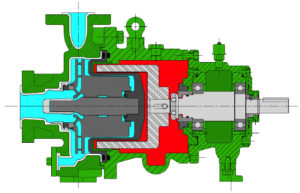

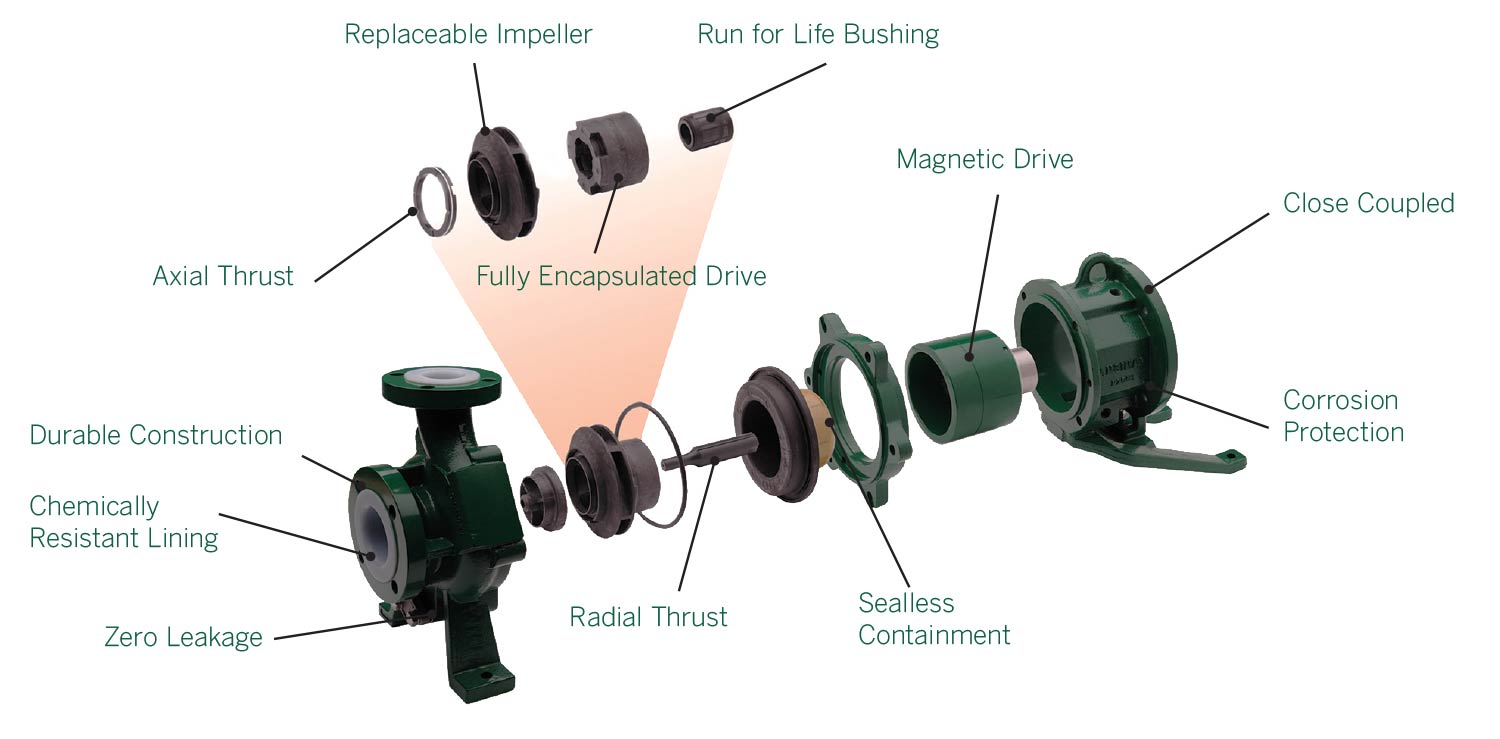

- Magnetic Drive: this patented technology hermetically seals the inner magnets, isolating them from process fluid, which maintains magnet integrity for the life of the unit.

- Close Coupled Design: leverages off-the-shelf NEMA C Face or IEC-B5 Flange motors, and still provides a small footprint, quiet operation and low maintenance.

- Corrosion Protection: Powder Coat exterior is more durable and chemically resistant than Epoxy based paints.

- Easy Service: ANSIMAG Back Pull Out design enables the pump to be serviced without removing the casing from the piping.

- Sealless Containment: Lined Kevlar Fiber/Epoxy construction provides unsurpassed pressure handling capability.

- Radial Thrust: All ANSIMAG pumps feature a fully-supported shaft to eliminate radial shaft deflection at low flow operating conditions.

- Zero Leakage: A single, fully-contained O-ring eliminates possible leakage.

- Chemically Resistant Lining: Carbon Fiber reinforced ETFE is resistant to most chemicals.

- Durable Construction: Ductile iron exterior is designed for heavy-duty chemical applications.

- Axial Thrust Washers: increase the allowable operating range over thrust balanced methods. This increases the pump’s reliability through a positive thrust surface that is unaffected by cavitation, solids or transient suction conditions.

- Simple Sealless Design: Consisting of only 9 wetted parts, ANSIMAG pumps can be quickly and easily repaired in the field. Routine maintenance or repairs can be performed without the need for special tools or training.

- Replaceable Impeller: a single-piece replaceable impeller is attached to the inner magnet drive via ANSIMAG’s patented tongue & groove system. The separation provides a cost effective approach to warehouse spare parts management and re-rating operations.

- Run-for-Life Bushing: Silicon Carbide bushings provide near maintenance-free operation for the life of the pump.

- Fully-Encapsulated Inner Drive: provides unsurpassed resistance to chemical attack.

Metric 50 Hz

- Heads to 105 m

- Flows to 150 m3/hr

- Maximum Motor Power 75 kW

- Temperature Range -29 to 121°C

- Maximum Case Working Pressure 19 bar

- Hydrotest Pressure 29 bar

- Maximum Viscosity 900 SSU (200 centistokes)

- Solids Range to 20%

- Bearing Materials Available Silicon Carbide, Carbon Graphite Optional

- Mounting Configuration Horizontal close coupled

- Dimensional Standards ISO 2858, ISO 15783

- Number of available hydraulics. 11

- Available Flanges ISO PN16 / ISO PN25

- Carbon Fiber Reinforced ETFE

- Glass Fiber Reinforced PFA (impeller parts)

- ETFE or PFA lined ductile iron (casing)

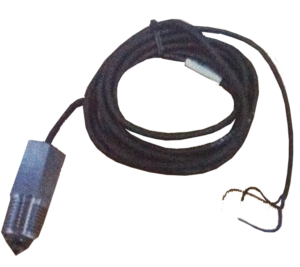

POWER MONITOR

Installed in the Motor Control Center (MCC), a power monitor measures the power required to operate the pump. By setting High and Low trip points, the power monitor is the perfect solution for protecting your pump from:

- Dry running

- Low flow operation

- High flow operation

- Severe cavitation

- Magnet de-coupling

Solids Handling

With its generous internal clearances, ANISMAG pumps are designed to handle liquids with solids up to 20%+ w/w, 1/8 inch diameter.

Unlike competitive designs, ANSIMAG pumps do not rely on close fitting internally wetted Silicon Carbide wear rings (held in place with non-metallic snap rings) that can trap solids or lock-up the pump.

Frequently Handled Solids:

- Inorganic Salts

- Fine Sand

- Caustic Precipitates

- TiO2(Paints & Coatings)

- Slag (Steel Pickeling)

- Carbon Black