Simple by Design

ANSIMAG features a unique combination of design features, application expertise and local support to provide process engineers and plant operators with the most reliable and safe sealless magnetic drive process pumps to keep their plants up and running.

ANSIMAG pumps provide a wide range of capabilities that are needed to handle harsh chemicals used in refining and petro-chemical applications. Each pump in the product family meets and exceeds all ASME/ANSI B73.3, B73.2 and ISO 2858 chemical process pump standards.

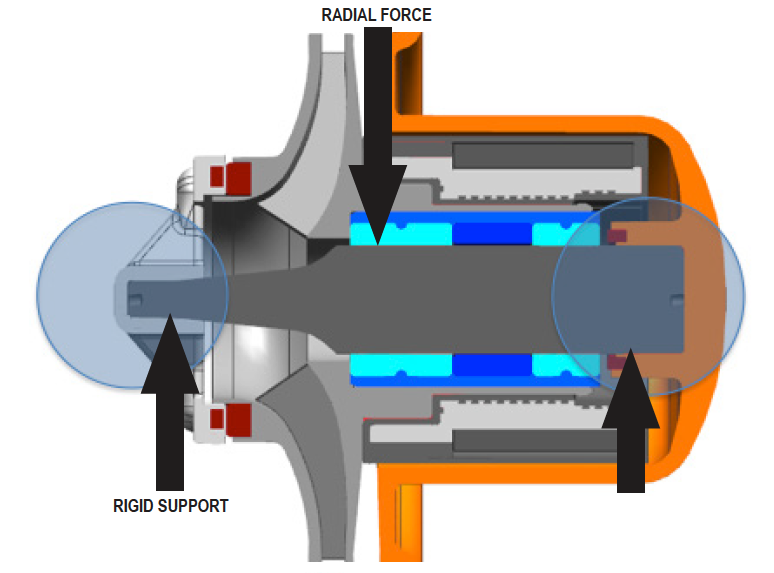

FULLY SUPPORTED IMPELLER

ANSIMAG pumps increase reliability by rigidly supporting the stationary pump shaft at the pump suction and rear containment shell, which prevents radial impeller deflection when operating at low flow (or off BEP) conditions. This support increases the pump’s allowable operating range, and also makes ANSIMAG pumps more reliable than cantilevered or overhung impeller designs.

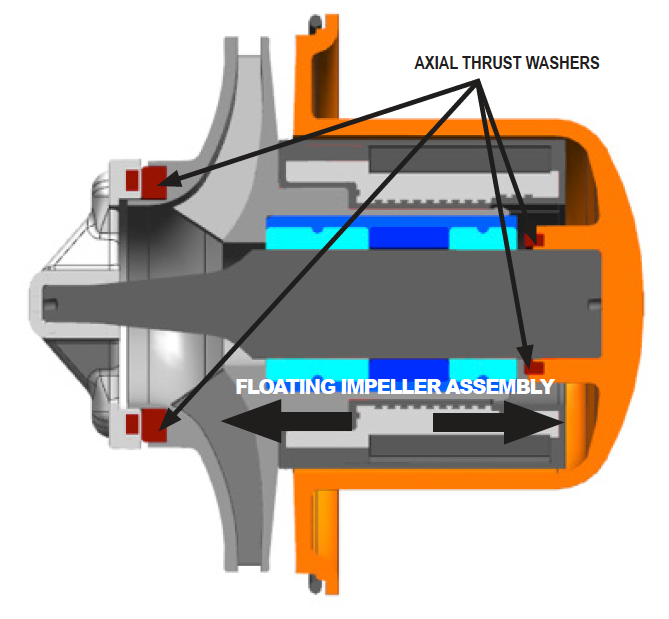

AXIAL THRUST WASHERS

Unlike competitive offerings, ANSIMAG pumps provide a positive thrust surface that is unaffected by cavitation, solids or transient suction conditions. Axial Thrust Washers increase the allowable operating range of the pump while also improving reliability compared to pumps with thrust balanced methods.

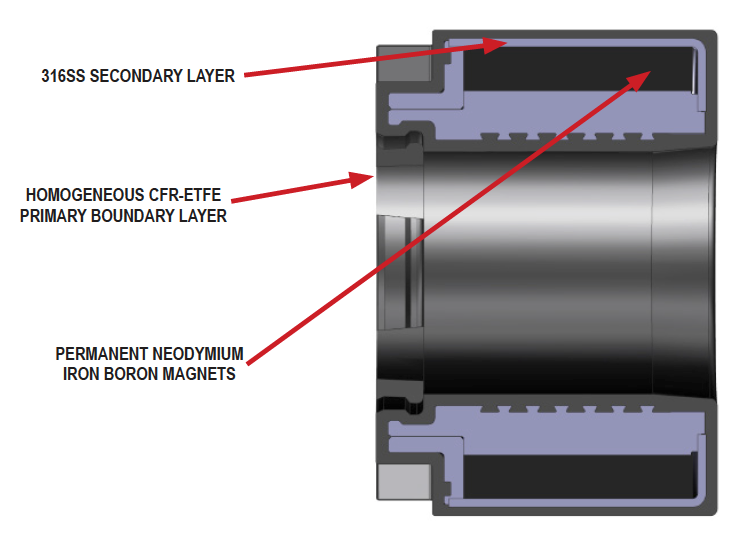

FULLY ENCAPSULATED INNER DRIVE

Patented inner drive encapsulation provides unsurpassed resistance to chemical attack. The integrity and strength of the magnets are maintained for the lifetime of the unit by hermetically sealing the inner magnets and isolating them from process fluid. A secondary stainless steel layer is also provided for increased durability.

REPLACEMENT IMPELLER

A single piece replaceable impeller is attached to the inner magnet drive via ANSIMAG’s patented tongue and groove system. The separation provides a cost effective approach to warehouse spare parts management and makes it easy to swap out the impeller as process conditions change.

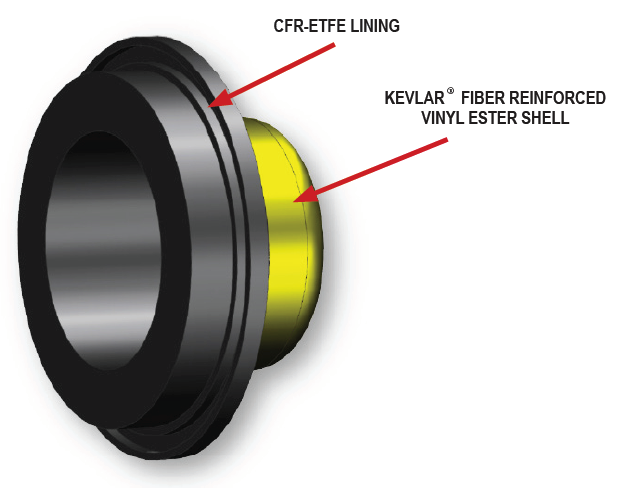

NON-METALLIC CONTAINMENT SHELL

This innovative CFR-ETFE lined rear casing generates zero hysteresis losses during operation, thus eliminating heat generation and reducing energy costs. With a burst pressure of 6X MAWP of the pump, the Kevlar fiber reinforced vinyl ester shell delivers unprecedented reliability, and makes ANSIMAG pumps more energy-efficient than mechanically sealed pumps.

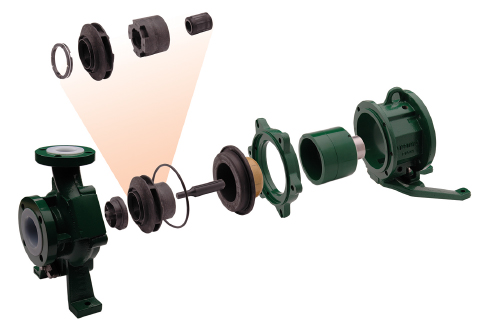

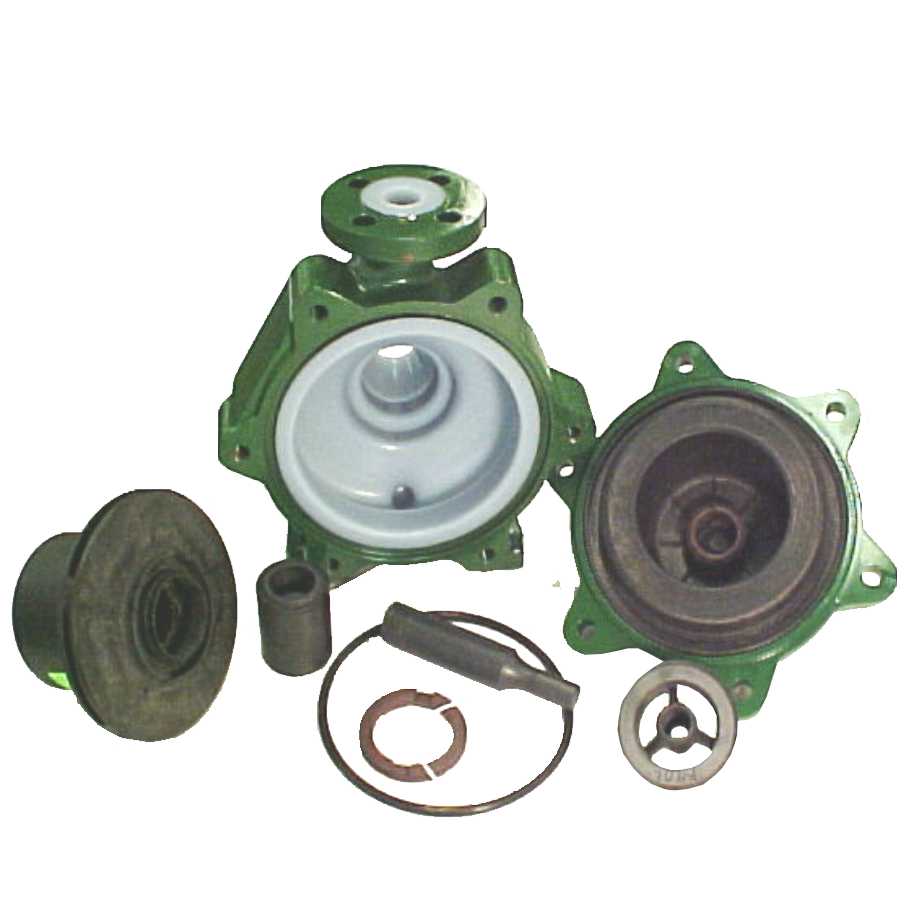

SIMPLE SEALLESS DESIGN

Consisting of only 9 wetted parts, ANSIMAG pumps can be quickly and easily repaired in the field. Routine maintenance or repairs can be performed without the need for special tools or training.

ANSIMAG

Competitor