We use Sundyne Compressors for gaseous phase polyethylene production mainly. Sundyne has a niche in smaller designs with smaller capacities. They are a good fit.

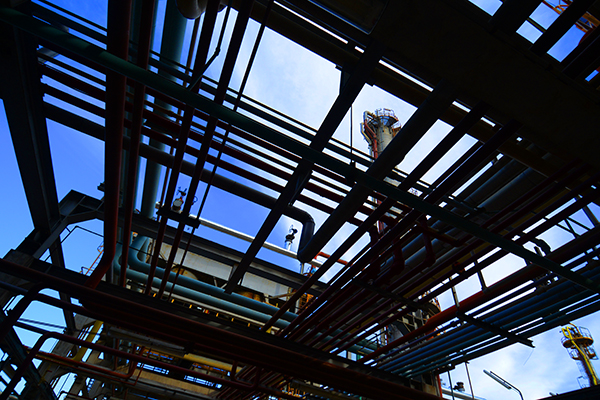

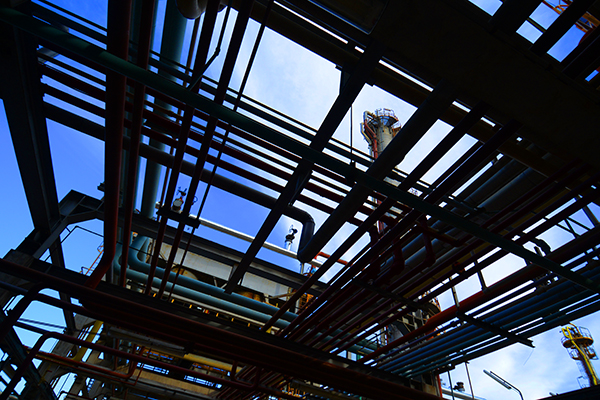

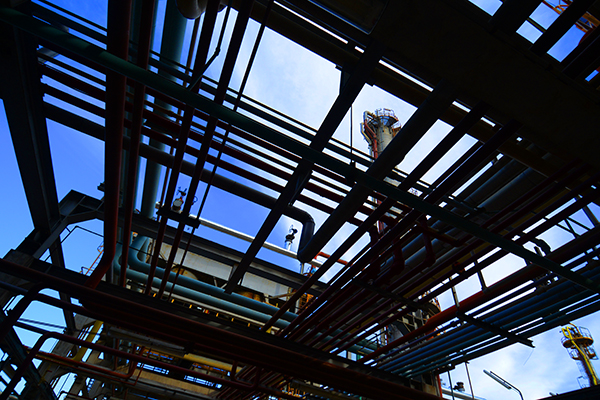

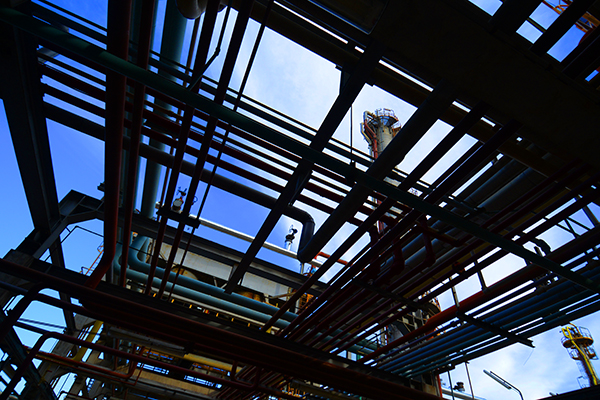

Safe and Efficient Pumps and Compressors for Chemical Production

The chemical processing industry consists of thousands of companies that convert oil, petrochemicals, natural gas, air, water, metals and minerals into tens-of-thousands of different products for use by both industry and households. Complex combinations of reaction, distillation, absorption, filtration, extraction, drying and screening operations are commonly utilized to produce chemicals. The equipment used for these processes must be corrosion-resistant and able to withstand elevated temperatures and pressures. Chemical processes must be efficient to save on resources, and safe to people and the environment. Sundyne centrifugal pumps and compressors are perfectly suited for these processes – and in many cases, they set the standard for industrial chemical production.

Bulk Chemicals

Process engineers in chemical plants satisfy global markets with large scale commodity chemicals. These commodities include organic and inorganic chemicals.

Polymers and Plastics

Major chemical companies use base chemicals to produce polyethylene for packaging films, bottles and containers; polypropylene for manufacturing packaging, appliances, clothing and carpeting; polyvinyl chloride for producing piping, construction materials and packaging; polystyrene used in packaging, toys, recreation and appliances. These polymers and plastics represent approximately 80% of the industry’s output worldwide.

Chlor Alkali

Bulk chemical process engineers introduce current into an aqueous/salt brine to produce chlorine and caustic soda (sodium hydroxide). Major markets, such as plastics and pharmaceuticals require chlorine for their manufacturing process. Caustic soda is a basic ingredient for paper, textiles, detergents, and most forms of industrial and municipal water treatment.

PTA – Purified Terephthalic Acid

PTA is primarily used as a precursor to manufacture polyester, which is used to make clothing and it’s also needed for plastic bottles. PTA is produced through a catalytic liquid phase oxidation of paraxylene in acetic acid.

Acids

The most common acids produced in chemical plants include sulfuric, phosphoric and nitric. These acids are utilized as base chemicals for production of industrial and household goods. Acids require specialized and safe handling by Sundyne sealless magnetic drive pumps.

Peroxides

Chemical reactions are initiated with various peroxides in manufacturing. Peroxides are used as oxidant and bleaching agents. They are also used as polymerization initiators, sources for phenol and acetone, and to make peroxysulfuric acid.

Ammonia

Global chemical production engineers utilize large-scale ammonia production plants to produce ammonia as a base chemical for fertilizer, plastic production, fibers, explosives, nitric acid and intermediates for dyes and pharmaceuticals.

Specialty Chemicals

Batch chemical plants manufacture thousands of specialty chemicals, such as: adhesives, agri-chemicals, cleaning products, cosmetics, liquids used for construction, elastomers, food additives, fragrances, industrial gases, lubricants, polymers, surfactants, and textiles.

Isocyanates

Chemical engineers produce isocyanates to manufacture flexible and rigid foams, fibers, and coatings, such as paints, varnishes and elastomers. Sealless magnetic drive pumps are used for the safe handling of these volatile chemicals.

Pharmaceuticals

Pharmaceutical companies utilize sterile processes and equipment on an industrial-scale to synthesize drugs for world-wide distribution. Process engineers in the manufacturing process utilize sealless magnetic drive pumps to keep the drugs sterile and pure.

Agricultural Chemicals

Chemical agents including herbicides and insecticides that are used to control crop-harming insects and weeds.

Herbicides

Chemical engineers manufacture herbicides which are commonly known as weed-killers. Producers are concerned about the safety of the active components used to manufacture herbicides. Sealless magnetic drive pumps offer a safe way to handle the ingredients and packaging of herbicides.

Fertilizer

The main nitrogen-based fertilizer is ammonia or its solutions. In a modern chemical plant, nitrogen fertilizer is produced from natural gas. In several transformative steps, natural gas (essentially methane) is combined with nitrogen to form nitrogen fertilizer. The main end products for fertilizer are ammonium nitrate and urea.

Urea

Chemical producers manufacture urea for use as a nitrogen-release fertilizer. It is produced from synthetic ammonia and carbon dioxide. As large quantities of carbon dioxide are produced during the ammonia manufacturing process as a byproduct from hydrocarbons (predominantly natural gas), or occasionally from coal, urea production plants are almost always located adjacent to the site where ammonia is manufactured. The urea production process requires extremely high pressure to make pellets from extremely viscous liquids.

Insecticides

Chemical companies produce these substances to kill insects in agriculture, medicine, industry and for sale to consumers. Many are toxic to both humans and animals, so safe handling with sealless magnetic drive pumps is environmentally responsible.

Biosides

A diverse group of poisonous substances including preservatives, insecticides, disinfectants, and pesticides are used to control organisms that are harmful to human or animal health, or that cause damage to natural or manufactured products. Manufacturers utilize sealless magnetic drive pumps throughout the process to safely handle the ingredients and final products in biocides.