For decades, Sundyne has worked with the world’s largest ammonia producers, pioneering many of the hydraulic solutions that are commonplace today. To learn more about Sundyne’s value proposition for ammonia production, click here.

About 80% of the ammonia produced by industry is used in agriculture as fertilizer, or as granular urea, urea ammonium nitrate (UAN), or ammonium nitrate (AN). Ammonia plays an important role in the energy transition because it is a flexible, long-term energy carrier and zero-carbon fuel. Ammonia is also used as a refrigerant gas for purification of water supplies, and it is used in the manufacture of plastics, explosives, textiles, pesticides, dyes and other chemicals.

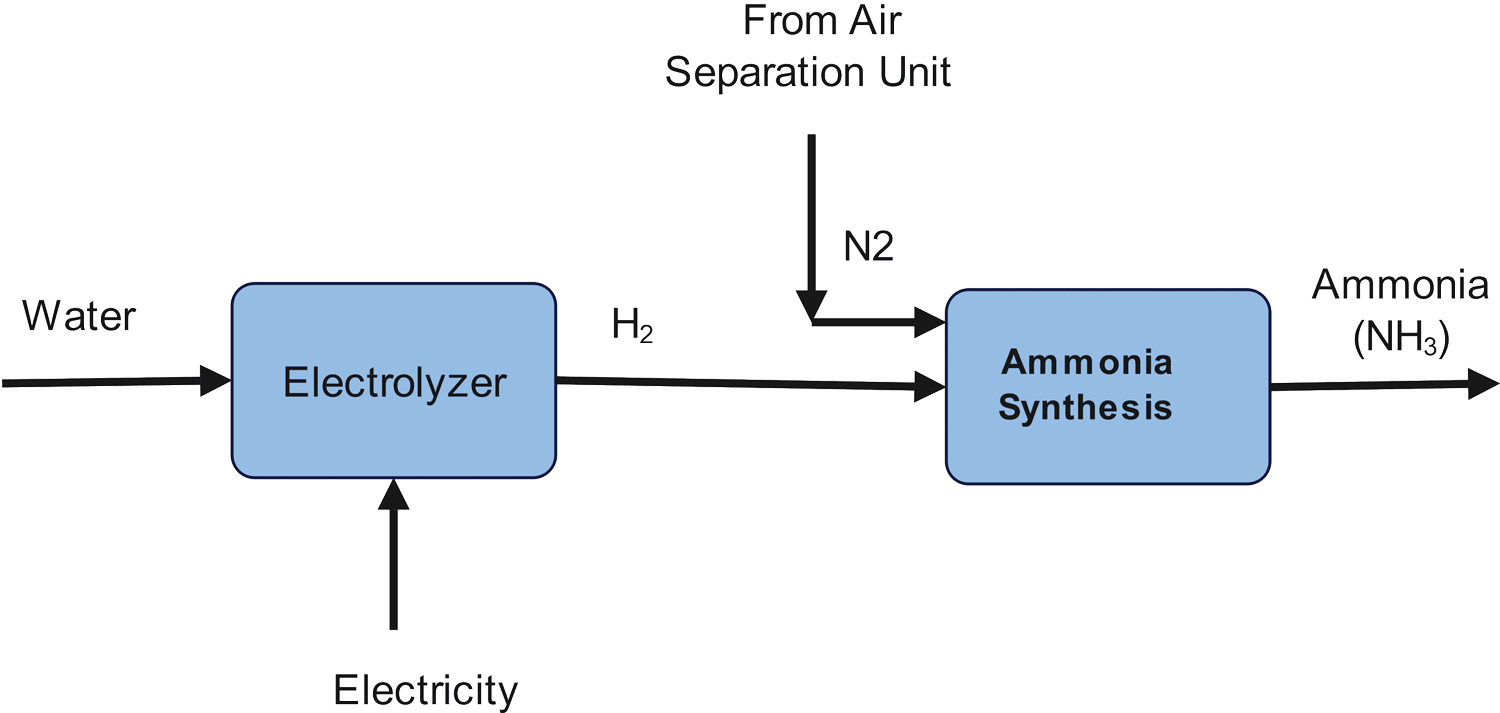

Green Ammonia

Ammonia can be made synthetically by combining nitrogen with hydrogen, in a process called ammonia synthesis. When this process is completed using renewable energy sources with zero carbon emissions (such as wind, solar, hydropower and geothermal energy) the result is green ammonia. Ammonia synthesis is achieved by combining green hydrogen and nitrogen at high temperature and pressures (modified Haber-Bosch Process):

Green Ammonia is often used as a:

- Hydrogen Carrier over long distances

- Fuel for engines, such as locomotives and ships, replacing diesel and marine fuel oil

- Fuel for electricity power generation

- Building block to make fertilizers, and a feedstock for industrial applications.

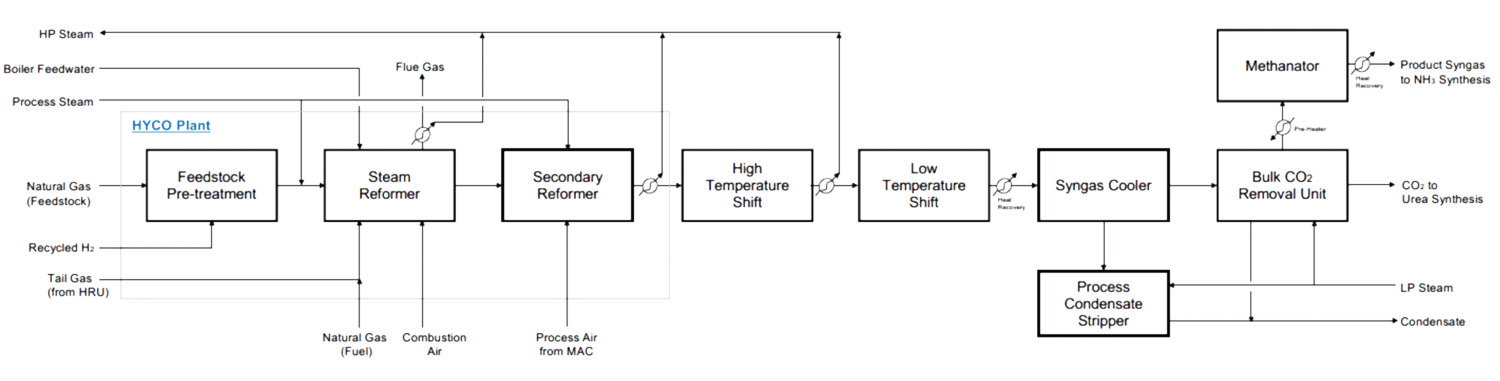

Blue Ammonia

Blue ammonia is made from nitrogen and hydrogen derived from natural gas feedstocks, with the carbon dioxide by-product from hydrogen production captured, utilized or stored (CCUS). The product characteristics of blue ammonia are identical to conventionally produced ammonia.

Blue Ammonia is manufactured by converting gaseous nitrogen (N2) and hydrogen (H2) in synthesis gas (Syngas) in the presence of a catalyst. The Syngas comes from Hydrogen, which is produced by reforming or gasification of fossil feedstocks combined with CO2 Capture.

Being a carrier of hydrogen energy, blue ammonia helps hard-to-abate sectors decrease their carbon intensity, such as transportation and power generation.

Pumps & Compressors for Green and Blue Ammonia Production

Some ammonia solutions (at concentrations of 25% or higher) are corrosive, so the hydraulic equipment used to produce ammonia must be durable and reliable. A wide range of pumps & compressors are used in Green and Blue Ammonia Production, including:

Pumps

- Boiler Feed Water Circulation Pumps

- Hydrogen Condensate Pump

- Sea Water Pump

- Cooling Water Pumps

- Corrosion Inhibitor Pumps

- Water Feed & circulation Pumps

- KO Drum Pumps

- Amine Circulation & Booster Pump

- Wash Water Pumps

Compressors

- Refrigerant Gas Compressors

- Hydrogen Recycle Compressor

- Fuel Gas Compressors

- Natural Gas Feed Compressor

- CO2 Compressor

- Molecular Sieve Regeneration Gas Compressor

- PSA Regeneration Compressor

- Gas Treatment Compressor

- Flare Gas Recovery Compressor

Recommended Sundyne Equipment

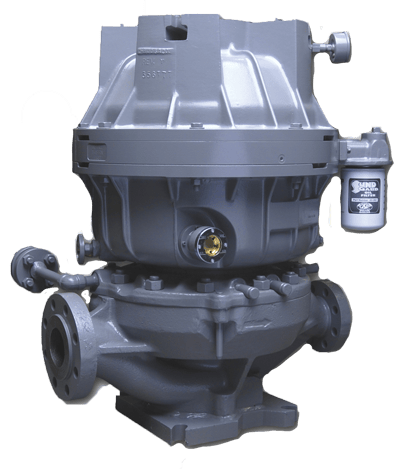

Sundyne LMV Pumps

Integrally geared pumps are designed for low-flow high-head applications such as pumping ammonia into a pipeline or pumping boiler feed water. The LMV pump features a single impeller running at high speed to produce high heads. This compact and simple design requires fewer spare parts than a multistage pump while offering much easier maintenance. Sundyne LMV pumps offer the highest efficiency in the low flow range. Sundyne’s advanced inducer technology solves situations where the NPSH available is limited.

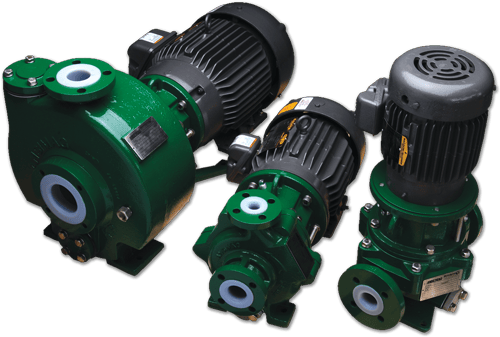

Sealless Magnetic Drive Pumps – HMD and ANSIMAG

Sundyne sealless pumps provide optimum safety and environmental protection for a wide range of ammonia applications. They are designed for hazardous and corrosive liquids, and applications that are difficult to seal. HMD Kontro metallic and Ansimag ETFE-lined sealless pumps ensure total product containment, increased reliability and uptime and simplified maintenance with no seals or seal support systems, whilst meeting industry standards such as ASME, ISO and API.

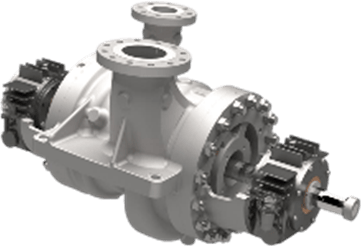

Marelli Pumps

Marelli pumps leverage a track record of more than 60 years in centrifugal pump design, development, manufacturing and service, to fulfill the latest standards for oil & gas, petrochemical and green markets, including carbon capture, H2, green and blue ammonia and biofuels processing. Marelli pumps are designed for extreme reliability and a wide range of flow rates, to accommodate the most stringent customer specifications.

Sundyne Compressors

Sundyne compressors leverage more than 60 years of experience and innovation from thousands of deployments in some of the world’s most demanding environments. Sundyne compressors feature single- and multi-stage centrifugal designs that are custom built to provide pulsation- and vibration-free operation, and to deliver oil-free process gas with zero emissions. Sundyne compressors offer the performance envelope, broad feature set and the reliability needed to address the B.E.P. for any application.

Criteria for Selecting Pumps and Compressors Used for Ammonia Production

- Reliability: ammonia plants are built to run for 20-50 years. Sundyne equipment has a service life of 30 years and some units have operated for more than 50 years.

- Efficiency: The footprint of Sundyne equipment allows users to install additional equipment in less space, like the addition of CO2 capture on existing plants. Sundyne’s 70-plus year track record makes it easy for operators to run equipment at B.E.P.

- Worker Safety Via Leak Free Operation: Ammonia compressors are subject to strict safety regulations. Sundyne liquid mechanical seals and dry-gas seals are proven for use in the petroleum, chemical and gas industry services. Ansimag and HMD sealless pumps are leak-proof by design, with fully enclosed wet-ends that eliminate leakage.

- Superior Chemical Resistance: Ammonia processing can wreak havoc on a pump’s internals. A wide range of metallic and ETFE materials are available to address any process requirement.

- Simplified Maintenance: The global volume of ammonia production illustrates the need for reliable equipment that minimizes plant downtime. Sealless pumps have fewer parts and no seal support systems, which increases Mean Time Between Maintenance (MTBM), and minimizes costs.

For decades, Sundyne has worked with the world’s largest ammonia producers, pioneering many of the technologies that are commonplace today. Sundyne’s value proposition for ammonia production is represented by reliable technology that’s easy to install and meets the toughest certifications in the industry.