What is CCUS (Carbon Capture, Utilization, Storage)?

Carbon Capture, Utilization, and Storage (CCUS) is a set of processes used to “capture” carbon dioxide (CO2) from emissions generated by large-scale industrial and power generation processes. CCUS is a decarbonization solution that can be used in any process that uses a fossil fuels – including power generation, steelmaking, cement production, refining and petrochemical production, natural gas processing, and ammonia and fertilizer production. Once CO2 is captured, it can be transported for use in certain industrial processes or for safe and permanent sequestration underground.

How is CO2 captured?

There are three main categories of carbon capture technology:

- Pre-combustion: removing CO2 from fossil fuels before combustion to produce syngas

- Post-combustion: separating CO2 from flue gas after fossil fuel or biomass combustion

- Oxy-fuel combustion: burning fuel with pure oxygen (rather than air), resulting in a nearly pure CO2 stream

Within each capture process technology, there are various CO2 separation techniques. These include absorption, adsorption, membranes, and cryogenics.

Once carbon dioxide is captured from an emissions source, it is dehydrated and compressed using a CO2 compressor to a supercritical state. From there, the supercritical CO2 is typically sent via pipeline to either an underground storage site or an industrial facility for CO2 utilization.

How is CO2 stored?

When stored, or permanently sequestered, the CO2 is injected deep underground into porous rock formations, such as saline aquifers or depleted oil & gas reservoirs. These geologic formations are thoroughly evaluated to ensure that the injected CO2 will remain trapped within the formation. After injection, continuous monitoring and verification is required to ensure there is no leakage back to atmosphere. In this way, carbon storage permanently stores CO2 that would have otherwise been vented to atmosphere at the emissions source.

How can CO2 be utilized instead of stored?

As an alternate to permanent sequestration, there is an emerging market for using CO2 as a feedstock to create new products. Key CO2 utilization examples include urea production, converting CO2 into synthetic fuels or chemicals, carbonation for food and beverage production, embedding CO2 into concrete or other building materials, and using CO2 as a coolant in industrial processes.

In these ways, CO2 utilization turns a waste product (carbon dioxide emissions) into a valuable new product, while also providing an outlet to avoid emissions to the atmosphere. This creates an additional value-stream that will help support the economics of carbon capture in the long-term.

What pumps and compressors are used in carbon capture?

As an OEM for both pumps and compressors, Sundyne offers the unique advantage of being able to provide a full range of rotating equipment services for carbon capture and CO2 handling. In the CCUS value-chain, Sundyne’s products are well suited for several key services and we are working with technology licensors, leading EPCs, and end-users across the value-chain to provide high quality rotating equipment. Key examples include application-specific packages for CO2 compression, centrifugal compressors for recycle and regeneration gas services, and sealless pumps for amine circulation and solvent make-up.

Sundyne’s comprehensive portfolio also gives us the ability to integrate multiple services within a single machine. For example, Sundyne is able to provide an integrated liquid-CO2 pump and CO2 compressor mounted on one skid with one motor. Whenever CO2 is compressed to a supercritical state or whenever CO2 is liquefied then pumped, a dual-service machine guarantees the best integration of process & control management within a compact and modularized arrangement.

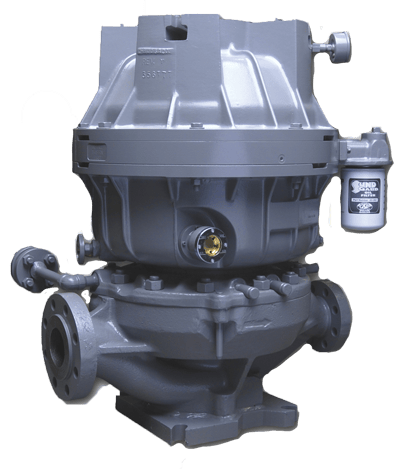

Sundyne Compressors

Sundyne’s Integrally Geared Compressor line features a robust and compact design with an integrated gearbox that runs multiple stages, resulting in space-saving installations. In CCUS applications, efficient and reliable compression of CO2 is critical for the success of projects. Sundyne compressors offer improved efficiency and precise control of operating conditions based on a full scope responsibility including process controls. With modularization of packaged solutions, Sundyne offers reduced lead-times and optimizes the total cost of a compression unit. Sundyne compressors, available from standard to full API compliant configurations, can operate continuously for up to 5 years without requiring maintenance or service.

Sundyne’s Integrally Geared Compressor line features a robust and compact design with an integrated gearbox that runs multiple stages, resulting in space-saving installations. In CCUS applications, efficient and reliable compression of CO2 is critical for the success of projects. Sundyne compressors offer improved efficiency and precise control of operating conditions based on a full scope responsibility including process controls. With modularization of packaged solutions, Sundyne offers reduced lead-times and optimizes the total cost of a compression unit. Sundyne compressors, available from standard to full API compliant configurations, can operate continuously for up to 5 years without requiring maintenance or service.

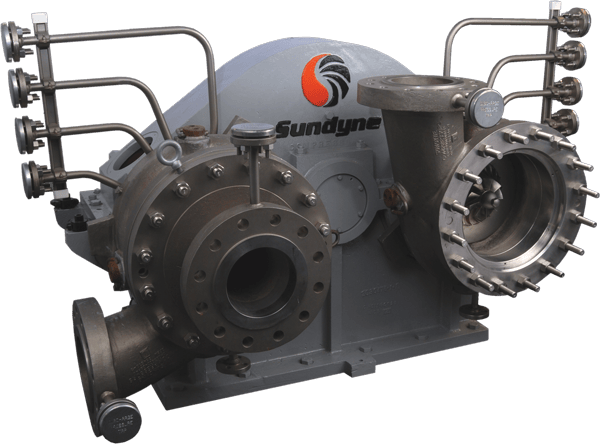

Sundyne LMV and HMP Pumps

Sundyne integrally geared centrifugal pumps are optimized for low flow-high head applications. They offer the best efficiency in the low flow range with a proven track record of high reliability. A single impeller in a Sundyne LMV pump spins at high speed to produce the same head as a multistage pump running at synchronous speed. Sundyne LMV pumps are ideally suited for services such as boiler feed water pumps, condensate pumps, solvent circulation pumps and reflux pumps. To achieve event higher heads, two or more integrally geared stages run in series in Sundyne HMP pumps. Such pumps can be used in liquid CO2 injection applications. The compact design reduces installation cost, and the simplicity limits the number of spare parts while making maintenance easier.

Sundyne integrally geared centrifugal pumps are optimized for low flow-high head applications. They offer the best efficiency in the low flow range with a proven track record of high reliability. A single impeller in a Sundyne LMV pump spins at high speed to produce the same head as a multistage pump running at synchronous speed. Sundyne LMV pumps are ideally suited for services such as boiler feed water pumps, condensate pumps, solvent circulation pumps and reflux pumps. To achieve event higher heads, two or more integrally geared stages run in series in Sundyne HMP pumps. Such pumps can be used in liquid CO2 injection applications. The compact design reduces installation cost, and the simplicity limits the number of spare parts while making maintenance easier.

Marelli Pumps

Marelli pumps leverage a track record of more than 60 years in centrifugal pump design, development, manufacturing and service. Marelli caters to global markets from conventional oil & gas and petrochemicals to fastevolving Clean Energy segments, including green/blue hydrogen, ammonia, carbon capture, and renewable fuels processing. Marelli covers a wide range of API 610 in OH, BB and VS types to meet stringent customer specifications.

Marelli pumps leverage a track record of more than 60 years in centrifugal pump design, development, manufacturing and service. Marelli caters to global markets from conventional oil & gas and petrochemicals to fastevolving Clean Energy segments, including green/blue hydrogen, ammonia, carbon capture, and renewable fuels processing. Marelli covers a wide range of API 610 in OH, BB and VS types to meet stringent customer specifications.

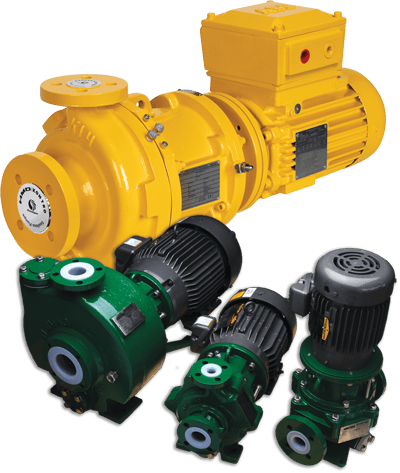

Sealless Magnetic Drive Pumps – HMD and ANSIMAG

Sundyne sealless pumps provide optimum safety and environmental protection for a wide range of applications in carbon capture and CO2 utilization. They are designed for hazardous and corrosive liquids, and applications that are difficult to seal. HMD Kontro metallic and Ansimag ETFE-lined sealless pumps ensure total product containment, increased reliability and uptime and simplified maintenance with no seals or seal support systems, whilst meeting industry standards such as ASME, ISO and API.

Sundyne sealless pumps provide optimum safety and environmental protection for a wide range of applications in carbon capture and CO2 utilization. They are designed for hazardous and corrosive liquids, and applications that are difficult to seal. HMD Kontro metallic and Ansimag ETFE-lined sealless pumps ensure total product containment, increased reliability and uptime and simplified maintenance with no seals or seal support systems, whilst meeting industry standards such as ASME, ISO and API.

Sunflo Pumps

Sunflo P-3000 Centrifugal pumps are fit-for-purpose, Industrial grade pumps designed for Low flow – High head applications, such as boiler feed water, condensate, and demineralized water circulation. The design development of Sunflo range pumps is built on Sundyne knowledge and experience of its API integrally geared pumps. A single impeller runs at high speed to produce high heads in a very compact and reliable design. The close coupled configuration eliminates alignment, simplifies installation while further reducing footprint. The Sunflo cartridge shaft assembly comes complete with all the rotating parts and enables quick and easy servicing of the pump in-place.

Sunflo P-3000 Centrifugal pumps are fit-for-purpose, Industrial grade pumps designed for Low flow – High head applications, such as boiler feed water, condensate, and demineralized water circulation. The design development of Sunflo range pumps is built on Sundyne knowledge and experience of its API integrally geared pumps. A single impeller runs at high speed to produce high heads in a very compact and reliable design. The close coupled configuration eliminates alignment, simplifies installation while further reducing footprint. The Sunflo cartridge shaft assembly comes complete with all the rotating parts and enables quick and easy servicing of the pump in-place.

| For additional examples and to see an overview of where our rotating equipment portfolio fits into standard carbon capture process flow diagrams, refer to our market brochure: |  |

To learn more about how Sundyne’s pumps & compressors are supporting Carbon Capture, Utilization and Storage (CCUS) around the globe, or to speak with a Sundyne representative about a project opportunity, please contact us.