Reliability and confidence for rotating equipment engineers

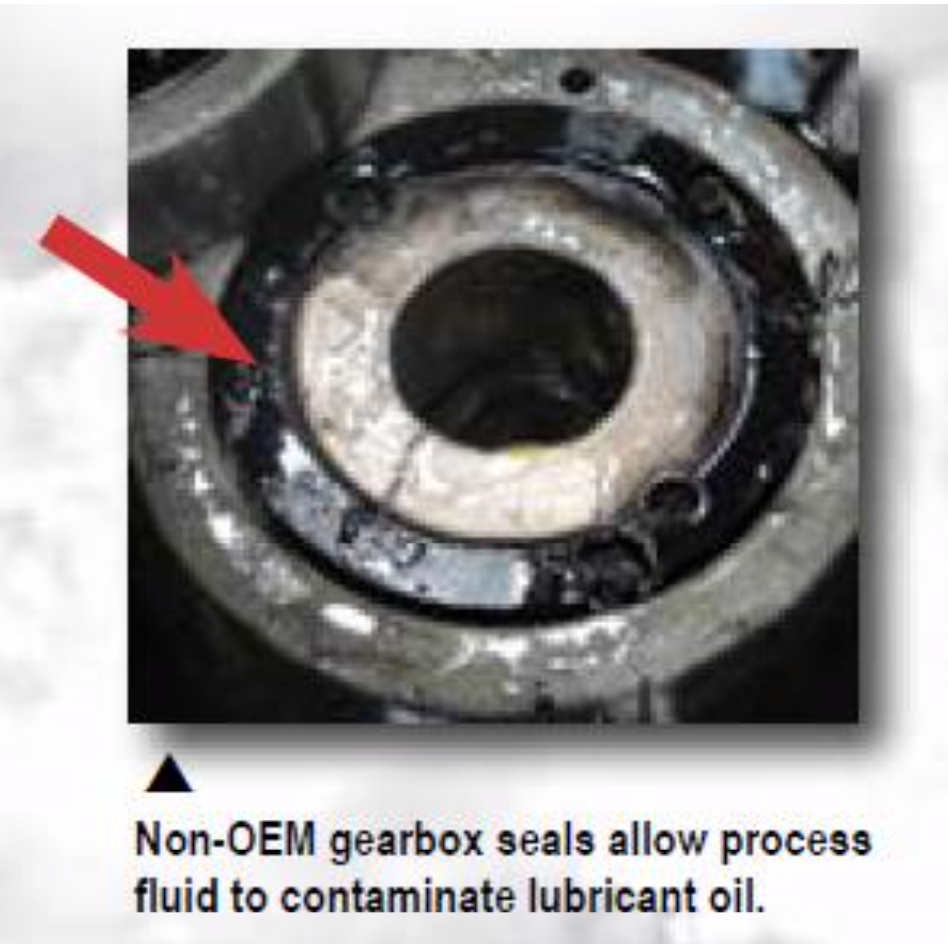

Precise tolerances are key to the performance of Sundyne pumps and compressors. Even the smallest variance can generate significant inefficiencies within a process flow and using non-OEM components dramatically increases the risk of equipment failure. These risks can be avoided by ensuring customers always use Sundyne Genuine Parts.

Sundyne Genuine Parts are machined accurately using advanced metallurgies, and are custom engineered to fit each specific machine. These precise tolerances are backed by decades of testing and development. Unlicensed fabricators, whose manufacturing processes fall short of the standards upheld at our global facilities, cannot duplicate the tolerances designed into our products. It is critical that our customers understand the dangers and risk of using replicator/pirated parts in Sundyne machines.

- Benefits

- Don't Risk Pirated Parts

- Reliability Assurance Kits

- Gearbox Exchange Program

- Gearbox Output Seal

- Anti-Friction Bearings

- Shaft Sleeves

- Journal Bearings

- Sundyne Oil Filter

- Desiccant Breather

- Lube Oil Pump

- Bearing Plate and Lube Pump Anti-Rotation Plate

- Gearbox Alignment Pins

- Low Foam Site Glass

- Gearbox Housing

- Downloads

Why You Should Use Sundyne Genuine Parts:

- High Quality Standards – Sundyne parts are engineered to rigorous standards and tolerances, then checked for dimensional integrity and accurate installation fit.

- Repair Specialists – Sundyne’s extensive network of authorized repair and overhaul facilities use Genuine Service and Parts to return older equipment to like-new condition.

- Warranty Protection – Genuine Service and Parts are warranted and their exclusive use protects the original warranty on existing Sundyne equipment. Additionally, using non-OEM parts can jeopardize ATEX certification and SIL level.

- 24-hour Support – We provide factory-based customer service and technical field support to our customers 24 hours a day, 7 days a week.

- Site Survey – To establish running parameters of working machinery, perform health checks and provide available upgrades

- Process Optimization – Establish baseline performance and design Re-rates to save power and enhance lifecycle MTBF

- Stock Optimization – Analyze your stock holding and advise upon Interchangeability and key components

- Hands-on Training – Sundyne offers hydraulic design basics and operations and maintenance training programs to ensure that end users can respond to changes in performance and understand the parts and service required for engineered machinery.

- Asset Management – provision of complete operation and maintenance packages for Sundyne Equipment with guaranteed performance commitments.

Look for the Sundyne Genuine Parts logo before installing any part in your pump or compressor.

Do Not Use Pirated Parts

Costs/Risks of using Pirated Parts:

- Costly Process Downtime

- Liability Exposure

- Health and Safety Issues

- Part Replacement Costs

- Repair Costs

- Environmental Impact

- Intensified Vibration Levels

- Increased Noise

- Higher Energy Consumption

- Increased NPSH Requirements

- Rework and Recycle Needs

- Fit and Assembly Problems

We work diligently to ensure appropriate legal action is taken when replicators are in violation of patents or misrepresent the parts they’re providing customers

Genuine Sundyne Parts Customized for Your Pump or Compressor on Site – Ready for Maintenance or Repairs

The new Sundyne Reliability Assurance Kit brings the reliability and efficiency of our recently released upgraded component parts to older generation machines. The upgraded components in the kits are designed to increase reliability and make units more tolerant to condition changes. These kits offer a simple and cost-effective way to rebuild a unit from the process seals all the way through the gearbox, improving performance and simplifying inventory management without the need for a direct replacement or a full conversion.

Key Benefits of Reliability Assurance Kits:

- Improved reliability & MTBF – genuine and specific spare parts for each unit.

- Better inventory management – the Sundyne Genuine Parts in the RAK are under a single part number versus having to track dozens of numbers in an ERP system.

- Ease of maintenance – parts are contained in a single heavy-duty package, which is easily purchased, stored and accessed by maintenance teams.

- RAKs are sealed to reduce – and even eliminate – part contamination and corrosion.

- Easy replenishment – used parts can be restocked by ordering a kit refill.

Parts and Data Included in the Reliability Assurance Kits:

- Upgraded Anti-Friction Bearings – increased efficiency and shaft longevity.

- Lube Pump Anti-Rotation Plate – higher radial shaft load tolerances.

- Gearbox SundSEAL – minimizes leakage, increases life span, and reverse pressure capable.

- Desiccant Breather – prevents moisture, reduces internal rust, and maximizes efficiency.

- Other standard wear parts – process seals, nuts, bolts, washers, screws, o-rings, etc.

- Spec Sheets.

- Performance Curves.

- Instruction and Operation Manuals, including cross-section drawings.

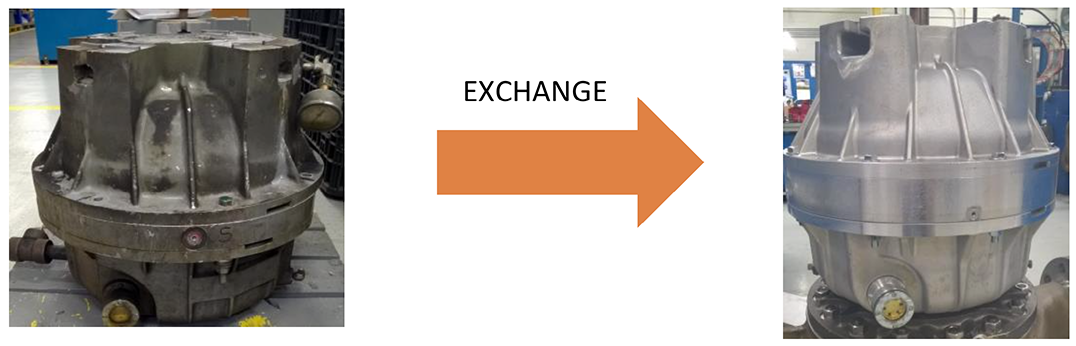

Return your Sundyne Pump or Compressor to Original Factory Performance Specifications

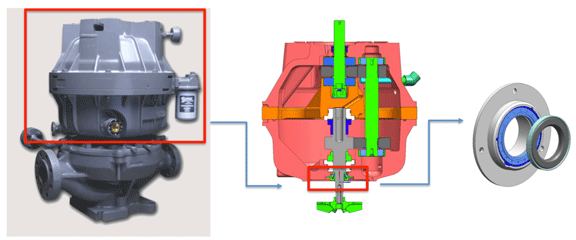

The Sundyne Gearbox Exchange Program offers end users a chance to return their Sundyne LMV, LMC, BMP or BMC gearbox to original factory performance specifications. The exchange is quick and cost effective while providing the many benefits of a brand new Sundyne gearbox. Once a customer puts in a request, Sundyne will ship the gearbox while the old unit is returned for a rebate.

Key Benefits of Gearbox Exchange:

- New unit provided with partial rebate credit for returned old unit.

- Significant savings compared to a new gearbox purchase.

- Includes most recent technology, parts, and metallurgies (seals, filters, lubrication, etc.).

- Improved reliability and extended operating life.

- Reduced noise and vibration levels.

- Easy and quick change in maintenance workshop (plug-in concept).

- Improved parts inventory, lowered risk.

Gearboxes received through the Exchange Program include a 12-month warranty from start-up, or 18 months from shipment. Note that normal delivery lead-time is 2 weeks for standard gearboxes with standard paint.

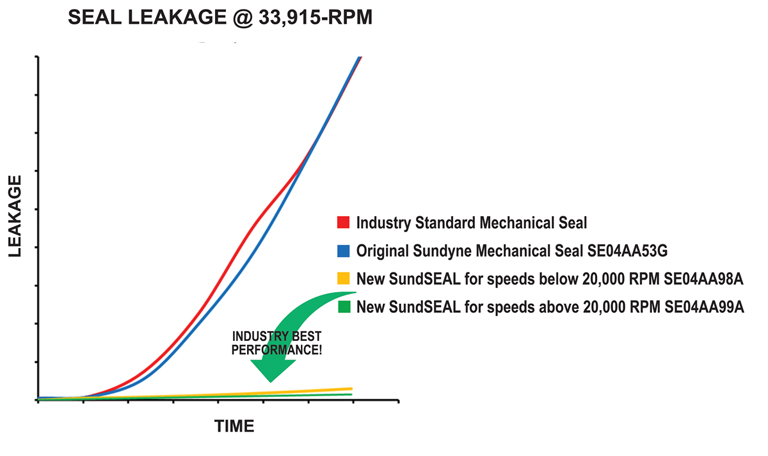

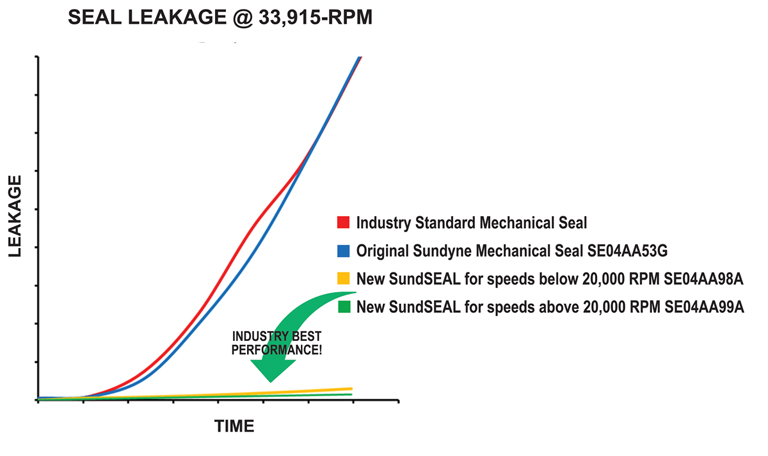

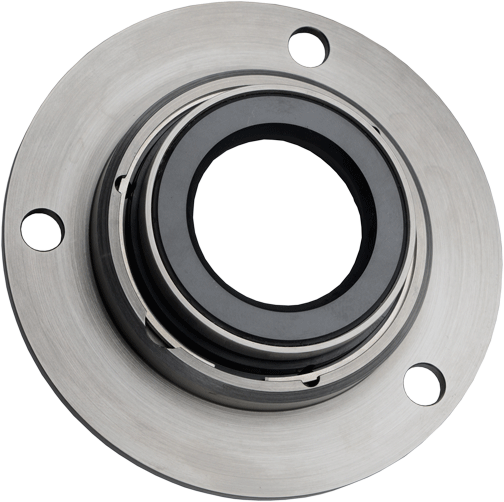

Increase your Sundyne pump reliability with a SundSEAL Gearbox Output Seal

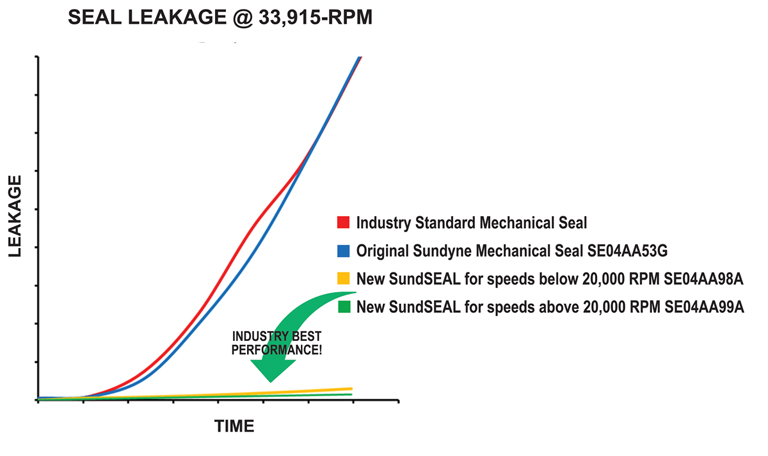

The new Gearbox Output SundSEAL is a proprietary, easy-to-upgrade seal that delivers a robust sealing interface. The new seal is proven to reduce leakage which, when configured with proper lubrication and system pressure management, vastly improves overall operational efficiency.

The Gearbox Output SundSEAL is suitable for any customer, application, or operating condition with an existing LMV/BMP-3XX pump or LMC/BMC-3XX compressor in operation.

The straightforward retrofit capability, makes the SundSEAL is an easy upgrade for existing Sundyne integrally geared pumps.

Reduction in Total Cost of Ownership

- Reduced downtime, improved operation time

- Extended maintenance intervals and reduced maintenance costs – longer seal life

Optimized Performance

- New port design for optimal drainage and pressure management

- Minimum leakage reduction of 50%

- The lower gearbox housing now has three additional passage ways connecting the oil sump area to the SundSEAL, improving the seal’s ability to control oil leakage

Added Gearbox Protection

- Reverse Pressure Capability up to 275 psi creates a barrier between the process seals and the gearbox interior, keeping process fluid out of the gearbox

Quick retrofit capability

- Easy, field installed upgrade for existing units

Sundyne Genuine Part

- Superior factory developed solution

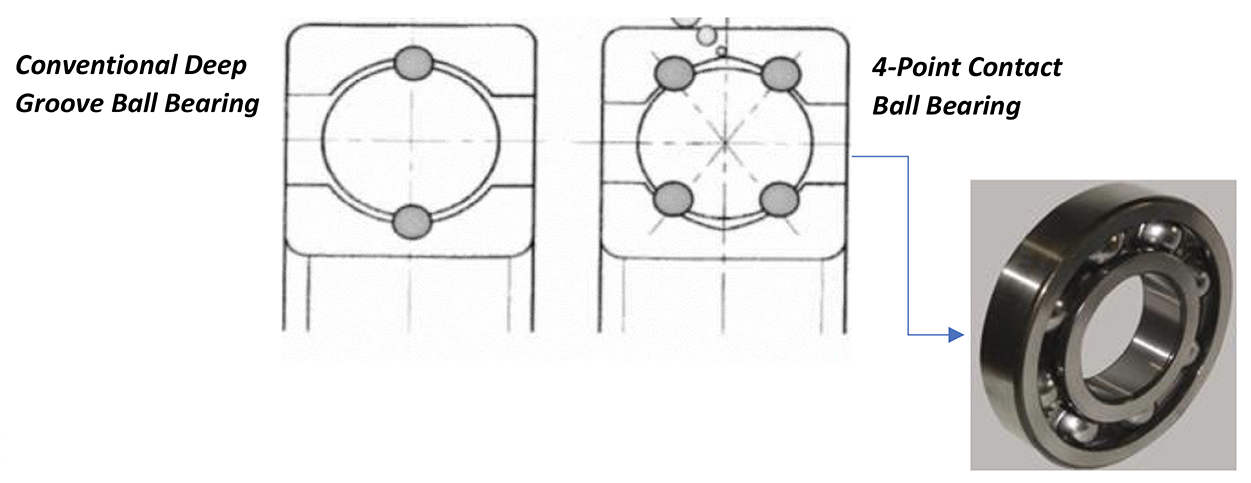

All Sundyne integrally gear drive pumps should be upgraded to the new anti-friction bearing (excluding LMV-34X models)

Ball bearings are designed to reduce rotational friction and support radial and axial loads. Most bearings use a 2-Point contact design limiting the load capability and life of the bearing. The new Sundyne anti-friction bearing is a proprietary bearing which provides a significant increase in bearing life.

Key Benefits of the Anti-Friction Bearings:

- API-610 compliant for L10 bearing life – 25,000 hours at rated point.

- Significant bearing life increases and reliability improvements over non-Sundyne bearings.

- Compatible with all Sundyne gear driven units except LMV-34X.

- Increased efficiency and shaft longevity – results in improved MTBR and reliability.

- Bearings are completely interchangeable.

Key Technical Specifications:

- 4-Point contact design – increased bearing life through additional load carrying capacity

- Steel vs Phenolic cage – stronger, more robust design.

- No filling slot – eliminating potential vibration and failure point.

- Proprietary design – only available for purchase from Sundyne.

Shaft sleeves are an extremely critical component of any pump or compressor

Using a non-genuine Sundyne shaft sleeve puts the process engineer’s plant at risk due to vibration, leaks and reduced reliability

Shaft sleeves are part of the high-speed shaft assembly stack up, meaning even the smallest deviations from required specifications can lead to mechanical seal leakage, excessive vibration and reduced reliability. Sundyne shaft sleeves are manufactured to precise tolerances that are far superior to any alternative on the market.

Applies to all Sundyne pumps and compressors – LMV-80X, LMV-32X, LMV-3XX, LMC-3XX, BMP-3XX, and BMC-3XX models

It’s common for maintenance departments at refineries, petrochemical-chemical plants and chemical manufacturing facilities to have established agreements with seal suppliers, including shaft sleeves. Sundyne routinely rejects the shaft sleeves offered by maintenance department suppliers as they do not meet the Sundyne precise specifications.

Key Benefits of Sundyne Shaft Sleeves:

- Increased reliability and MTBR compared to non-Sundyne sleeves.

- Improved tolerances leading to increased seal life and reduced vibration.

- Field installation capability.

- Sundyne sleeves will operate properly at speeds up to 24,000 rpm.

- Compatible with all Sundyne pump and compressor models.

Key Technical Specifications of Sundyne Shaft Sleeves:

- Measured to flatness at 0.00002 inches (1/10th the thickness of an average hair.)

- End-to-end parallelism at 0.0003 – reducing potential seal leakage.

- 17-4 precipitation hardened stainless steel instead of 316 stainless steel – increased strength to maintain shape when loaded up by the required axial stack up.

- Tolerances checked with granites per Federal Specifications GGG-P-463C Grade A – grade B granites are commonly used on non-Sundyne sleeves and are not adequate.

Journal bearings should be replaced during any gearbox maintenance or reliability upgrade

Applies to all Sundyne integrally geared drive pumps – LMV/BMP-3XX models

Journal bearings are a vital component of all Sundyne pumps and compressors with high radial and/or thrust loads. They provide a sheared layer that allows the surface of the shafts to slide relative to the stationary part of the machine – essentially, they protect the shafts by separating them from the gearbox. In depth technical knowledge of each Sundyne unit and advanced manufacturing capabilities are required to properly size the Sundyne journal bearing to the precise measurements necessary for optimal operation. Failing to meet these specifications puts the Sundyne pump or compressor at risk of premature failure.

Key Benefits of Sundyne Journal Bearings:

- Engineered to fit individual pump and compressor specifications. Sundyne engineers and machinists have decades of experience and unparalleled product knowledge necessary to manufacture journal bearings to precise sizes and tolerances.

- Non-contact journal bearings – significantly prolonged bearings and shaft life.

- Advanced sizing tool to identify optimal journal bearing.

Key Technical Specifications of Sundyne Journal Bearings:

- Critical variables that determine journal bearing sizes are depth and width land length, bearing surface design, oil temperature, flow rate, pressure, and lube groove location.

- Each bearing is custom designed for individual serial numbers.

- Dimensional interchangeability, bi-directional operation, and proprietary leaded-bronze.

- Improved washer design – distributes oil flow more uniformly between the rotating shaft and stationary thrust bearing.

- Testing for tapered land design yields 85% increase in load carrying capacity with a more concise repeatability of the overload limit.

The ultimate in oil protection for Sundyne pumps and compressors

Oil filters provide critical protection for sensitive bearings, gears, and seal components in the Sundyne gearbox against the harmful effects of contamination. The SundGARD oil filter is engineered to high specifications providing substantial reliability and performance.

Using non-Sundyne oil filters can damage or crash your pump and compressor gearbox, leading to production losses and costly maintenance.

Key Benefits of the Sundyne Oil Filter:

- Unique helical-wrap pleat support systems and composite element structure that provide high beta rations to achieve extremely low contamination levels necessary to stop the chain reaction of abrasive wear.

- Captures contaminates so effectively that bearing service life is extended by as much as 6X, providing significant maintenance cost savings and greater system uptime.

- Designed for purpose – Sundyne Genuine Part engineered to maximize reliability and uptime.

- Field installation capable – the filter should be stocked and replaced regularly to ensure proper filtration

Key Technical Specifications:

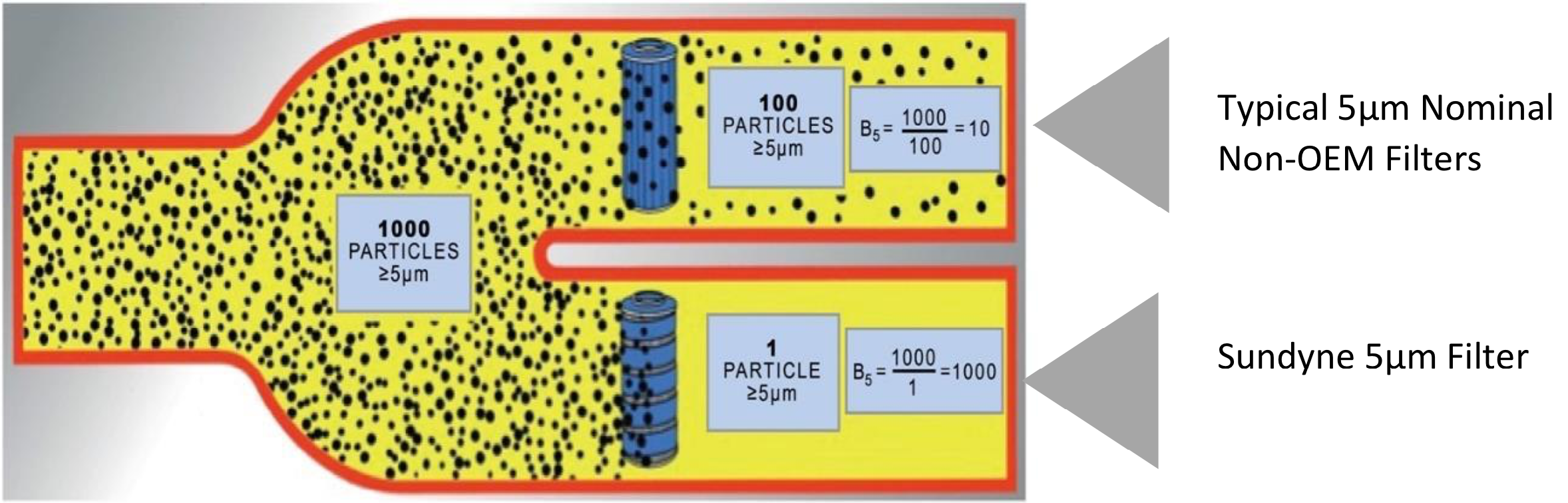

- Rated at B5 = 1000, meaning no more than one out of 1000 particles 5 microns or larger entering the filter will pass downstream.

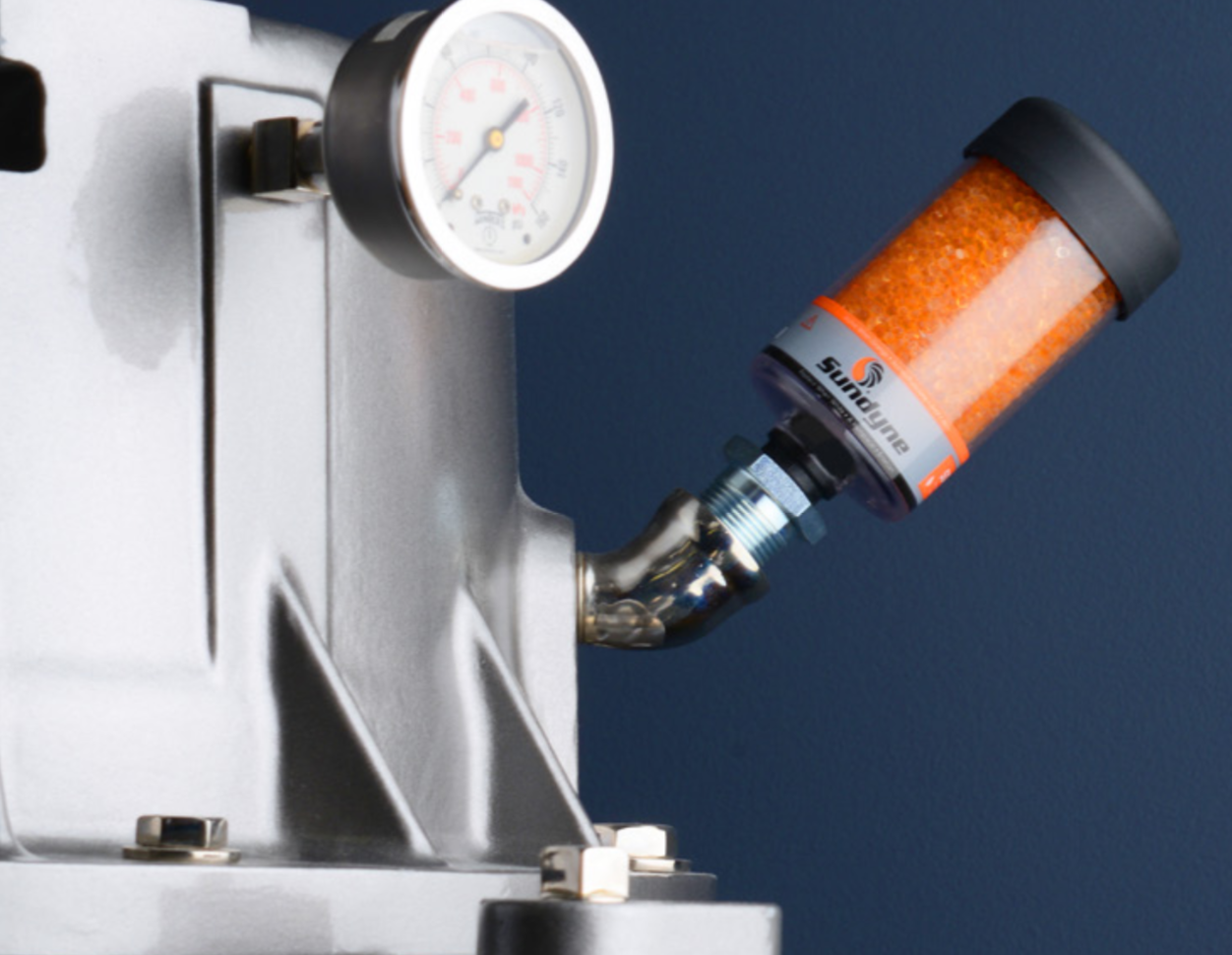

The Sundyne desiccant breather is designed to protect your gearbox from corrosion and contamination

The gearbox is the heart of your Sundyne integrally geared pump or compressor. Keep your gearbox running reliably and maximize MTBR, by protecting the interior components from moisture and particulates.

Avoid costly downtime and achieve a lifetime of reliability, today!

All Sundyne gear driven pumps and compressors – LMV-3XX, LMC-3XX, BMP-3XX, and BMC-3XX models should have the new desiccant breather.

Key Benefits of the Sundyne Desiccant Breather:

- Designed for purpose – Sundyne Genuine Part engineered to protect gearboxes from corrosion and contamination.

- Durable outer casing and robust connection – designed to stand up to the environmental rigors of the process industry.

- Easy field installation – Simply unscrew and replace the original breather on the gearbox air intake with the Sundyne desiccant breather.

Key Technical Specifications of the Sundyne Desiccant Breather:

- Subject to 100% humidity at 70o F ambient temperature, the breathers reduced the humidity in the gearbox by 80-85%.

- Moisture-absorbing silica gel media and particulate filtering polyester elements.

- Check valves located at the base of the breather allow air exchange only when necessary – extending the life of the breather

The Sundyne lube oil pump was designed specifically for Sundyne gearboxes to maximize uptime and extend MTBR

Proper lubrication is critical to keeping Sundyne machines operating at optimum levels. A lube oil system that operates properly decreases friction, reduces wear, protects from corrosion, absorbs heat, reduces noise, and helps prevent damage from debris.

The new lube pump is compatible with all LMV-31X and LMV-32X 50 hp and 200 hp gearboxes.

Key Benefits of the Sundyne Lube Oil Pumps:

- Reduction in total cost of ownership – designed to keep Sundyne machines operating longer at lower temperatures, minimizing downtime, extending maintenance intervals and reducing maintenance costs.

- Sundyne Genuine Part – superior factory developed solution with a new rugged design that eliminates pin shear.

- Added gearbox protection – improved gearbox lubrication.

- Optimized performance – with the addition of the carbon bushing and the newly developed drive lugs help reduce wear inside the lube pump.

Key Technical Specifications of the Sundyne Lube Oil Pump:

- Wear between the drive pins and the gearbox input shaft was improved. After an analysis of the contact area between the old drive pins and the input shaft, drive lugs were developed to reduce wear between the two parts.

- Wear inside the lube pump is also reduced by the addition of a carbon bushing and a coated bronze bearing, as shown by the red arrows in the photo below.

- New lube pump PU01AB06 height reduced by 0.045” from PU01AB05 – providing additional clearance for older models.

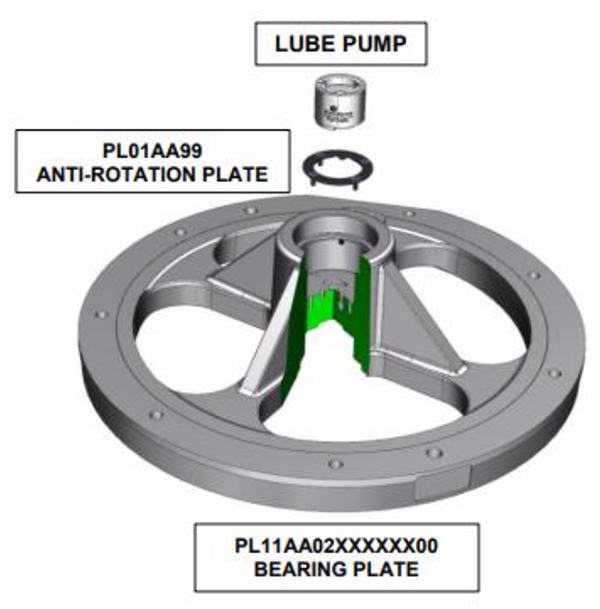

The Sundyne bearing plate provides critical support for the Sundyne pumps and compressors.

Support for the lube pump, which lubricates the entire gearbox, the lower radial bearings for the input shaft, and the upper thrust and radial bearings for the high-speed shaft. Manufactured to precise tolerances, even slight deviations from specification can cause significant damage or catastrophic failure.

Key Benefits of Sundyne Bearing & Lube Anti-Rotation Plate:

- Increased operational reliability and robustness

- Designed for use with all existing Sundyne lube pumps

- Field installation capability with retrofit option for all LMX-31X models in operation.

- Superior lube pump anti-rotation reliability – through elimination of spiral pin.

Key Technical Specifications of Bearing & Lube Anti-Rotation Plate:

- The new bearing plate has a larger diameter lube pump housing bore and four threaded holes that locate and anchor the anti-rotation plate.

- To use the PL01AA99 anti-rotation plate, existing bearing plates require replacement and upgrade to PL11AA02XXXXXX00.

- The PL11AA02XXXXXX00 bearing plate was configured so that all previous bearing plate versions could be obsoleted. Bearing plate part numbers that have been obsoleted include – PL01AA05XX, PL01AA17XXXX, PL01AA96XX0000

- The redesign requires two additional parts be sold with the bearing plate. To simplify, four common bearing plate builds (representing 90% of all 31X sales) have been configured that include the additional parts – consult Sundyne for configurations.

This upgrade is available to you:

- Part is available individually or as part of a Reliability Upgrade Kit (RUK) which includes all upgraded component parts for LMX-31X machines – consult Sundyne for unique part number(s).

- Another alternative is a gearbox exchange which comes pre-assembled with all the upgraded component parts – plug-in repair concept.

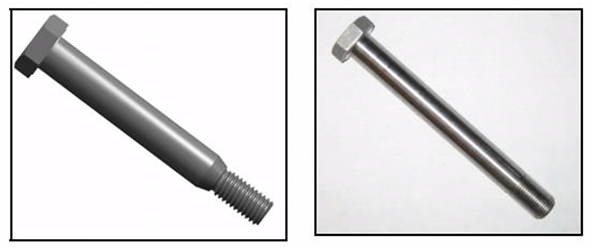

Upgrade your Sundyne gearbox with quick installation of Genuine Sundyne gearbox alignment pins

All Sundyne gear driven pumps and compressors – LMV-3XX, LMC-3XX, BMP-3XX, and BMC-3XX models.

Sundyne pumps and compressors are designed to last. One of the original Sundyne pumps with a serial number from the 1960’s is still in operation today. In order to maximize the life of a Sundyne gearbox, routine maintenance and repairs must be completed. Repeated assembly and disassembly of the gearbox housing causes wear of the close tolerance alignment bolt holes. The upgraded Sundyne alignment bolts use new material that eliminate wear and prevents misalignment of the gearbox housing.

Key Benefits of Sundyne Gearbox Alignment Pins:

- Reduction in total cost of ownership – eliminates misalignment of gearbox housings.

- Added gearbox protection – eliminates unnecessary vibration from misalignment.

- Sundyne Genuine Part – superior factory developed solution.

- Quick retrofit capability – easy, field installed upgrade for existing units.

Key Technical Specifications of Sundyne Gearbox Alignment Pins:

- Smaller thread diameter and a gentle lead in chamfer to the bolt shank – eliminates wear on the gearbox housing alignment hole.

- Interchangeable with existing housings – the hold size has not changed.

- Same threads as older bolts – same nuts and washers can be used.

The new gearbox alignment pin is more robust and reduces vibration compared to the old pin (right).

Make sure your oil levels are maintained to keep your Sundyne gearbox running optimally and efficiently

All Sundyne gear driven pumps and compressors – LMV-3XX, LMC-3XX, BMP-3XX, and BMC-3XX models.

Proper lubrication is critical to keeping Sundyne pumps and compressors operating at optimum levels. In order to ensure the lubrication system is functioning properly, accurate oil levels must be maintained. The new Sundyne low foam sight glass provides a significant improvement from previous designs, providing much more accurate oil level readings at all oil temperatures and operating speeds.

Key Benefits of Sundyne Low Foam Sight Glass:

- Added gearbox protection – accurate oil level readings allow customers to be proactive in maintaining their Sundyne machine, eliminating unnecessary failures.

- Easier maintenance – quickly identify oil levels and have confidence the readings are accurate.

- Quick retrofit capability – easy, field installed upgrade for existing units.

- Sundyne Genuine Part – superior factory developed solution.

Key Technical Specifications of Low Foam Sight Glass:

- The low foam sight glass works on the principle that the oil is maintained in the extended sight glass for a longer period allowing entrained air to be released.

- Extensive factory testing, which included running a gearbox at 34,000 rpm for an extended period and filling the gearbox with cold oil (at its pour point) to ensure an accurate oil level can be read while filling regardless of the oil temperature.

New low foam site glass (right) to insure your gearbox is effectively lubricated to keep your Sundyne pumps and compressors running reliably.

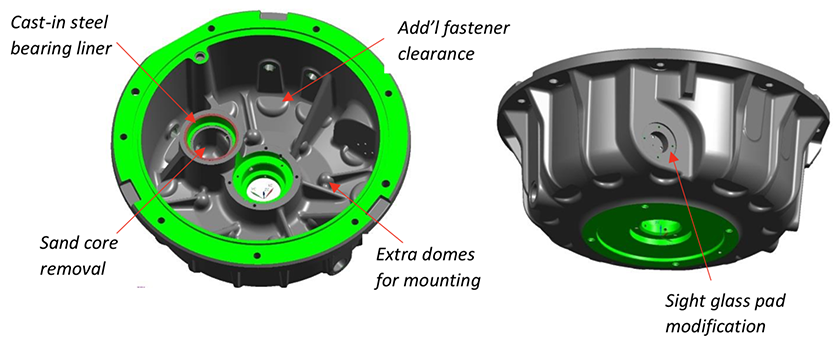

Sundyne gearbox housings are critical to the performance of Sundyne pumps and compressors

Compatible with all LMX / BMX-31X AND LMV-32X pumps and compressors.

Gearbox housings provide a few key functions on a Sundyne gearbox – they’re a fixture for the alignment of the gears and shafts, they support for the motor, and they provide environment protection for the internal components. Build with advanced metallurgies to specific sizes and tolerances, Sundyne gearbox housings are not easily replicated and are critical to the performance of the Sundyne machine.

Key Benefits of Sundyne Gearbox Housing:

- Reduction in total cost of ownership – reduction in porosity improves structural integrity leading to extended maintenance intervals.

- Improved MTBR – cast-in bearing liner yields more consistent and controlled features which ensures critical internal gearbox components (shafts and gears) are properly aligned.

Key Technical Specifications of Gearbox Housing:

- Cast-in bearing liners – stronger, more robust design improves housing life and maintains internal part alignment.

- New sophisticated tooling for permanent mold castings.

- Better surface finish.

- Increased mounting capacity to the seal housing.

- Dimensionally interchangeable with older designs.

Sundyne Genuine Parts Brochure, US – PDF

Sundyne SundGARD Oil Filter, US – PDF

Sundyne SundGARD Oil Filter, A4 – PDF

Sundyne Gearbox Reliability Upgrade Kit Flyer, US – PDF

Sundyne Gearbox Reliability Upgrade Kit Flyer, A4 – PDF

Sundyne Gearbox Exchange Flyer, US English – PDF

Sundyne Gearbox Exchange Flyer, A4 English – PDF

Sundyne Gearbox Exchange Flyer, A4 Mandrin – PDF

Sundyne Gearbox Exchange Flyer, A4 Korean – PDF

Sundyne Gearbox Exchange Flyer, Deutsche – PDF

Sundyne Gearbox Exchange Flyer, Espanol – PDF

Sundyne Gearbox Exchange Flyer, Portuguese – PDF