Utilizing genuine parts and service gives process engineers confidence in their Marelli API Pumps

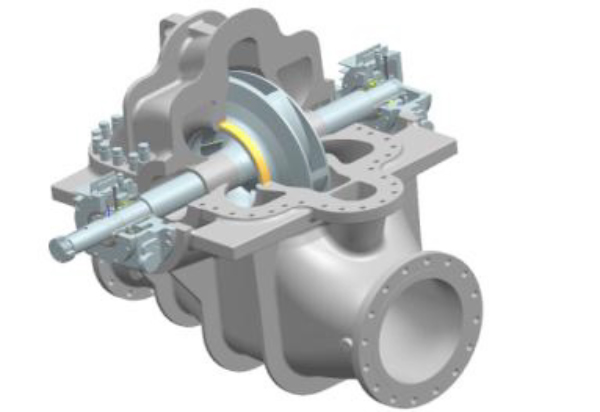

Marelli API Pumps are engineered to exact specifications according to process and rotating equipment engineer’s needs. To improve reliability and efficiency, Marelli has made investments in upgraded component materials, including shafts, shaft sleeves, impellers, and casings. These parts are extremely critical to the performance of Marelli pumps, even the smallest deviations from required specifications can lead to mechanical failure, excessive vibration, and reduced reliability.

Reduce your Total Cost of Ownership

- Reduced downtime, improved operation time

- Extended maintenance intervals and reduced maintenance costs – longer seal life

- Quick retrofit capability

- Easy, field installed upgrade for existing units

- Marelli Genuine Part – superior factory developed solution

Key Benefits of the material upgrade:

- API-610 compliant.

- Significant pump life increases and reliability improvements.

- Compatible on all Sundyne Marelli products.

- Increased efficiency and longevity – results in improved MTBR and reliability.

Key Technical Specifications:

- Proprietary design and compatibility study – only available for purchase from Sundyne.

- Upgraded component parts are available for all customers and models.

- Inventory should be kept on hand, allowing for quick installation or replacement.

- Older units – upgrading to new parts is recommended.

- Units with excessive parts consumption should be reviewed for potential upgrades.

- New process conditions are excellent candidates to discuss upgraded parts or conversions/rerates.

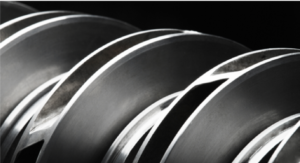

Designed to reduce rotational friction, the nonmetallic wear-rings reduce clearances according to API, improving efficiency and reliability

Shaft sleeves and wear-rings are extremely critical components for the efficiency of Marelli pumps. The smallest deviations from required specifications can lead to excessive vibration and reduced reliability. Sundyne non-metallic parts are manufactured to precise tolerances that are far superior to any alternative on the market.

Key Benefits of Nonmetallic Wear-Rings:

- API-610 compliant.

- Significant pump life increases and reliability improvements.

- Increased efficiency and impeller/casing longevity – results in improved MTBR and reliability.

- Wear-rings, shaft sleeves, and impellers are completely interchangeable with existing part numbers.

- Improved tolerances leading to increased pump life and reduced vibration.

- Field installation capability – engineers can be confident they’re getting a factory developed solution designed for their pump.

- Compatible with all Marelli pump models.

Key Technical Specifications:

- API-610 compliant.

- Eliminates potential vibration and catastrophic failures.

- Software Simulation CFD.

- Quick prototyping.

- 3D Scanning.

- Proprietary design – only available for purchase from Sundyne.

Process and Rotating Equipment Engineers must consider:

- All Marelli pump models where efficiency is critical for operation.

- It’s common for refineries, petrochemical and chemical plants to have established agreements with 3rd party suppliers, that include wear-parts. Marelli routinely rejects the sleeves and wear rings offered by these suppliers as they aren’t able to meet precise specifications. Engineers should replace shaft sleeves and wear-rings with Marelli original parts.

- Consider fixing bad actors and machines experiencing excessive vibration or loss of efficiency.

- All products suitable for improving efficiency and hydraulic behavior.

Proper lubrication is critical to keeping Sundyne Marelli machines operating at optimum levels

An oil system that operates properly decreases friction, reduces wear, protects from corrosion, absorbs heat, reduces noise, and helps prevent damage from debris. Pure and Purge Oil Mist was designed specifically for Marelli pump bearing housings to maximize uptime and extend MTBR.

Key Benefits of Pure and Purge oil mist:

- Reduction in total cost of ownership – designed to keep Sundyne Marelli machines operating longer at lower temperatures, minimizing downtime, extending maintenance intervals and reducing maintenance costs.

- Reduced oil consumption.

- Increased bearing life.

- Improved mechanical seal life – when bearings last longer so do seals.

- Decreased manpower for lubrication tasks.

- Fewer oil changes.

- Increased safety / reduced fire risk – oil mist is a lean mixture that will not support combustion and will not explode.

- Maintenance teams have more time to focus on high priority tasks and initiatives – oil mist allows for less time working on lubrication systems.

- Superior critical component protection when pump is idle – reduces surface corrosion.

- Field installation capable – bearing covers, deflectors, and oil rings can be replaced in the field without major modifications.

- OH2, BBX models experience the biggest improvement from using oil mist.

- Perfect for spare units or grass-roots projects during the construction phase.

- Inventory should be kept on hand, allowing for quick installation or replacement.

Genuine Sundyne Parts Customized for Your Pump or Compressor on Site – Ready for Maintenance or Repairs

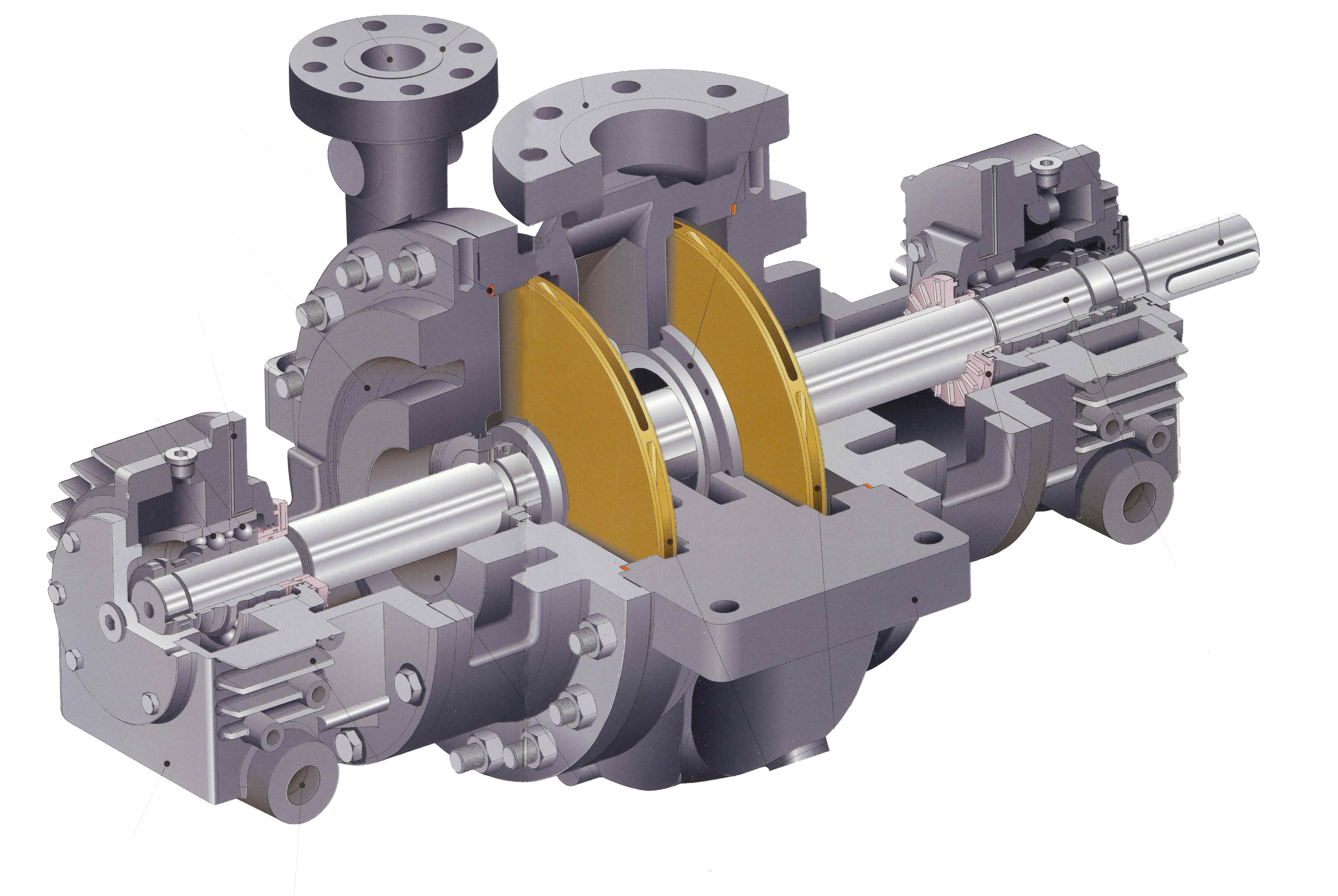

The new Sundyne Reliability Assurance Kit brings the reliability and efficiency of our recently released upgraded component parts to older generation machines. The upgraded components in the kits are designed to increase reliability and make units more tolerant to condition changes. These kits offer a simple and cost-effective way to rebuild a unit from the process seals all the way through the gearbox, improving performance and simplifying inventory management without the need for a direct replacement or a full conversion.

Key Benefits of Reliability Assurance Kits:

- Improved reliability & MTBF – genuine and specific spare parts for each unit.

- Better inventory management – the Sundyne Genuine Parts in the RAK are under a single part number versus having to track dozens of numbers in an ERP system.

- Ease of maintenance – parts are contained in a single heavy-duty package, which is easily purchased, stored and accessed by maintenance teams.

- RAKs are sealed to reduce – and even eliminate – part contamination and corrosion.

- Easy replenishment – used parts can be restocked by ordering a kit refill.

Parts and Data Included in the Reliability Assurance Kits:

- Upgraded Anti-Friction Bearings – increased efficiency and shaft longevity.

- Lube Pump Anti-Rotation Plate – higher radial shaft load tolerances.

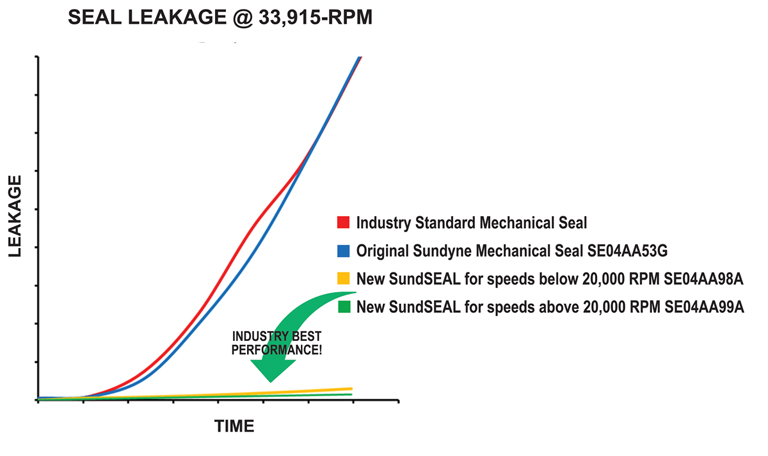

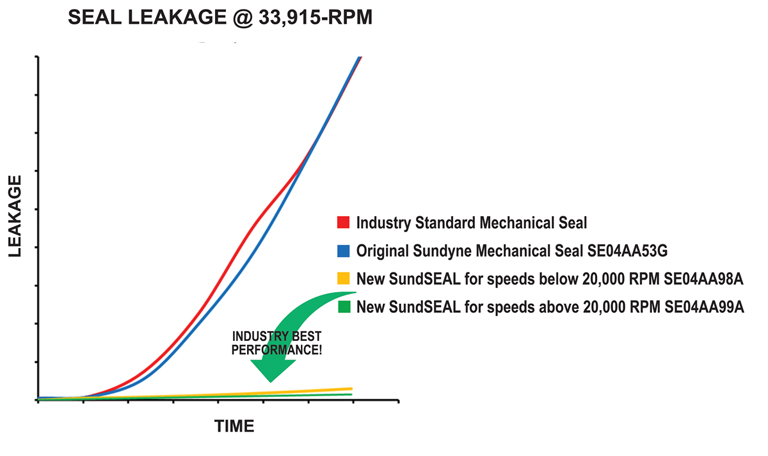

- Gearbox SundSEAL – minimizes leakage, increases life span, and reverse pressure capable.

- Desiccant Breather – prevents moisture, reduces internal rust, and maximizes efficiency.

- Other standard wear parts – process seals, nuts, bolts, washers, screws, o-rings, etc.

- Spec Sheets.

- Performance Curves.

- Instruction and Operation Manuals, including cross-section drawings.

Sundyne Genuine Parts Brochure, US – PDF

Sundyne Genuine Parts Brochure, A4 – PDF

Sundyne SundGARD Oil Filter, US – PDF

Sundyne SundGARD Oil Filter, A4 – PDF

Sundyne Gearbox Reliability Upgrade Kit Flyer, US – PDF

Sundyne Gearbox Reliability Upgrade Kit Flyer, A4 – PDF

Sundyne Gearbox Exchange Flyer, US English – PDF

Sundyne Gearbox Exchange Flyer, A4 English – PDF

Sundyne Gearbox Exchange Flyer, A4 Mandrin – PDF

Sundyne Gearbox Exchange Flyer, A4 Korean – PDF

Sundyne Gearbox Exchange Flyer, Deutsche – PDF

Sundyne Gearbox Exchange Flyer, Espanol – PDF

Sundyne Gearbox Exchange Flyer, Portuguese – PDF