Genuine HMD Kontro sealless magnetic drive pump parts and service to give plant operators piece of mind

Plant operators need reliable sealless magnetic drive pumps to keep their chemical and hydrocarbon processing plants running efficiently. We continuously innovate and integrate new technology into our pumps to keep plant operations running smoothly and reliability.

At HMD Kontro, we stock inventory and manufacture replacement parts in our state of the art plant to speed delivery to your doorstep.

Process engineers – Lower your energy requirements with higher efficiency

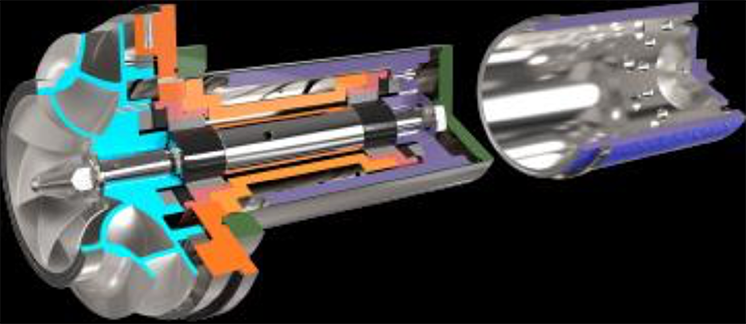

The ZeroLoss Containment Shell is a revolutionary new feature offered on HMD sealless magnetic drive pumps. The containment shell was designed to dissipate heat, helping to prevent flashing and vaporization, two common sources of failure in magnetic drive, sealless pumps. Made from PEEK Composite material, the ZeroLoss Shell provides a more efficient and robust alternative to traditional metallic containment shells. ZeroLoss shell conversions are available for many HMD pumps originally supplied with metallic containment shells.

ZeroLoss Containment Shells are especially effective for light hydrocarbon applications (specific gravity between 0.4 and 0.6) – because they are susceptible to flashing.

Conversion available on all GSA/I Frame 1 / 2, GSP Frame 1 / 2 / 3, GSPV, GSPLF, LMV-801 and GSPX.

Key Benefits of the ZeroLoss Containment Shell:

- Increased efficiency and reduced power consumption

- Elimination of eddy current losses leading to significant energy savings and lower life cycle costs – reduced power consumption leads to potential payback within 1 to 3 years on energy savings alone.

- Reduced carbon footprint and enhanced environmental benefits.

- More robust design and optimized MTBF

- Complete elimination of inductive heating, reducing heat transfer into the process liquid reducing the risk of flashing, which is often the cause of magnetic drive pump failure.

- Improved handling of volatile and heat sensitive liquids.

- More resilient for closed discharge or potential dry-run scenarios.

- Improved margin-to-safety flash factor – reduced risk of premature failure.

- Increased time for operator intervention during system upsets

- Simple retrofit capability

- Easy, field installed conversion for existing units

- ZeroLoss conversion kit available as an Insurance Spares Kit option.

Key Technical Specs for the ZeroLoss Containment Shell:

- API compliant, 40 bar rated.

- Suitable for operating temperatures from -148° to 248°F (-100° to 120°C)

- Engineered from hi-tech PEEK (PolyEther Ether Ketone) Composite material.

- High electrical resistivity – leads to zero losses.

- High strength – 5X lighter than steel but just as strong.

- Inert to a wide range of chemicals.

- Not affected by sub-zero temperatures.

- Thermal shock resistant.

- Similar form factors to existing metallic shells.

Plant operators – Increase your MTBF

Made from Ceramic Matrix Composite material, the CMC thrust bearing is an alternative to the standard Silicon Carbide internal thrust bearing material. The CMC Thrust Bearing conversion is suitable for any operating temperatures and process liquids, and offers a more robust design solution for volatile and marginal pumping applications.

GSA/I Frame 1 / 2, GSP Frame 1 / 2 / 3, GSPV, GSPLF, LMV-801 and GSPX.

Especially suited for refining and chemical plants with:

- Services containing liquified gases or heat sensitive liquids.

- Low NPSHa applications or those with an increased risk of dry-running.

- The ZeroLoss Shell conversion is also recommended with CMC Thrust Bearing Conversion.

Key Benefits of the CMC Thrust Bearing Conversion:

- More robust design and optimized MTBF

- Mode of failure far more benign than the standard SiC / SiC internal being design.

- Improved handling of volatile and heat sensitive liquids.

- More resilient for closed discharge or potential dry-run circumstances.

- Low cost conversion opportunity

- Minimal replacement parts required, only the internal thrust bearing.

- Short lead time component.

- Simple retrofit capability

- Easy, field installed conversion for existing units.

- CMC Thrust Bearing conversion kit available as a Service Kit option.

Process and rotating equipment engineers will increase bearing life and pump reliability

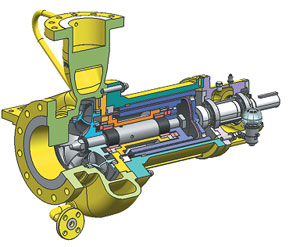

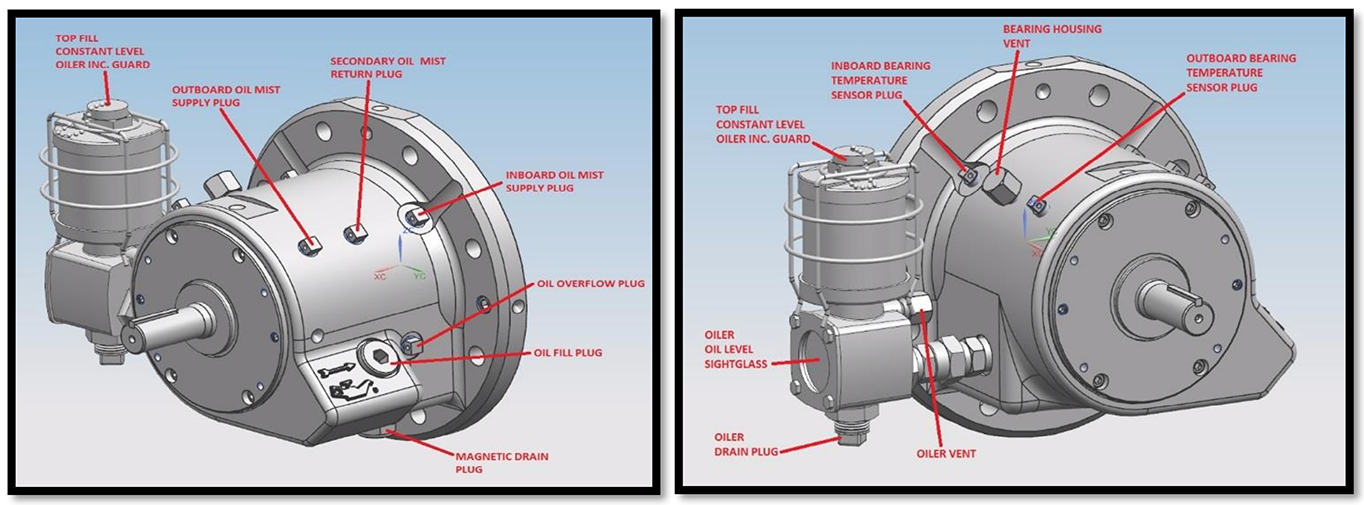

To prevent oil over-filling on site and to enable bearing monitor devices to be fitted, HMD has developed a modular bearing housing for the HMD GSP pump range. The bearing assembly is designed to improve robustness, enhance the options available, and facilitate upgrading while being offered as an upgrade option for existing GSP pumps.

Available on GSP Frame 1 / 2 / 3 pumps

Especially well suited for refineries and chemical plants with sealless magnetic drive pumps with the following parameters:

- Sites with a history of over-filling bearing housings.

- GSP installations where alternative bearing seals or oil mist lubrication is required, or where external bearing monitoring (e.g. vibration and/or temperature monitoring) is required.

Key Benefits of the GSP External Bearing Assembly Upgrade:

- The new design prevents the risk of oil over-filling, increasing bearing life.

- Allows for alternative bearing isolators to be installed.

- Vibration sensor and temperature sensor provision supplied as standard, enabling these monitoring devices to be retrofitted.

- Includes provision for oil mist bearing lubrication.

- Optimized interchangeability.

- Modular design for quick and easy retrofit to GSP pumps in the field.

Maintenance made faster and simpler

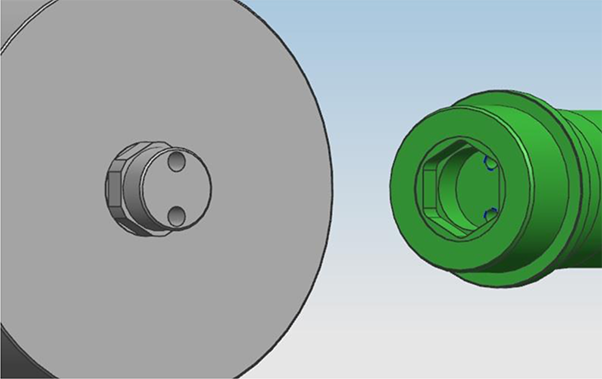

HMD has developed a Hexagon Outer Magnet Ring (OMR) Drive as an upgrade option to the existing eccentric drive design. The upgrade allows for quicker re-assembly of the bearing housing during routine maintenance activities, reducing pump downtime. The Hexagon OMR Drive is a robust alternative to the eccentric drive design and may be the preferred option for process and rotating engineers.

GSA/I Frame 1 / 2 and GSP Frame 1 / 2 units

Key Benefits of the Hexagon OMR Upgrade:

- Hexagon OMR Drive preferred by customers as it is easier to re-assemble than an eccentric drive design, allowing for quicker bearing replacement and reducing downtime during planned maintenance activities.

- More robust than the eccentric drive design leading to increased MTBF.

- Upgrade can be completed quickly and easily in the field.

Sealless Magnetic Drive Pump Protection for Process Plants

Power Monitoring represents one of the best values available today to protect your pump from system upset damage and avoid costly shutdowns, unexpected repair costs, and premature equipment failures. A SundGard power monitor senses true power input and can be set to alarm or shut off if preset power limits are exceeded. By simply monitoring motor input power, nearly all pumping conditions that typically damage pumps can be quickly detected and avoided.

For use with any HMD pump

Detectable Pumping Conditions include:

- Dry-running

- Low Flow/Back-on-Curve

- Increased Viscosity/Precipitation

- Deadhead/Closed Discharged Valve➢ High Flow/End-of-Curve

- Jammed Impeller

- Severe Cavitation

- Decoupling (Magnetic Drive Pumps)

Key Benefits of the SundGard Power Monitor:

- Minimizes pump damage due to system upsets.

- Reduces downtime, service and spares parts costs.

- Integral current transformer eliminates extra component and installation costs.

- Provides valuable feedback to troubleshoot operational problems.

Genuine HMD Parts Customized for Your Sealless Magnetic Dive Pump on Site – Ready for Maintenance or Repairs

Leveraging over 70 years of sealless magnetic drive technology experience, our technical team has conducted a comprehensive analysis of the most common repairs and typical maintenance issues. Through this analysis HMD has developed a broad portfolio of spare parts kits that can beheld in stock by end users, or at HMD Kontro’s regional hubs, to ensure a quick, easy and economical repair of sealless pumps onsite.

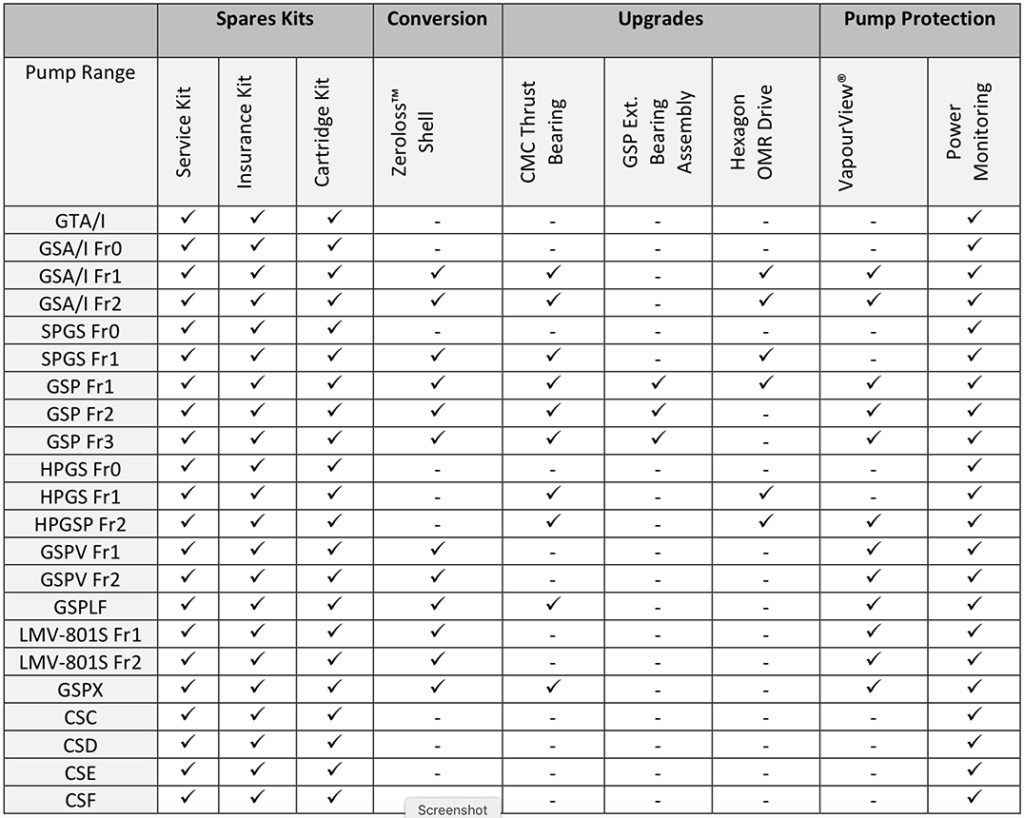

Service, Insurance and Cartridge Kits are available for all HMD pump ranges

Key Benefits of HMD Spare Parts Kits:

- Improved reliability & MTBF – genuine and specific spare parts for each unit.

- If held on-site, End Users will benefit from maximized process uptime while ensuring continuity of operational safety.

- Better inventory management.

- Easy replenishment – used parts can be restocked by ordering a kit refill.

Types of Spare Parts Kits:

Service Kits

- Designed to address standard maintenance requirements in regular services, these kits contain bearings, gaskets and O-rings.

- We recommend these kits be kept in stock for planned maintenance procedures.

- Parts included in the kit:

- Product Lubricated Bearings

- Gaskets

- O-Rings

Insurance Spares Kit

- Insurance Kits represent the best value solution for sealless pump repair while in place. It comes at a discounted price compared to the sum of the individual parts contained. Designed to provide uptime continuity, it resolves most pump failures.

- Parts included in the kit:

- Internal Magnet Ring (IMR)

- Outer Magnet Ring (OMR)

- Containment Shell

- Product Lubricated Bearings

- Gaskets

- O-rings

- Conveniently packaged, the kit can be held in stock or ordered as required.

- Simple, quick installation with replenishment as parts are used.

- Significantly shorter lead times than a cartridge.

- Ideal for applications with fewer critical uptime considerations. These kits can also be used to repair damaged cartridges that can then be kept on hand as another standby.

Cartridge Assembly Kit

- The drop-in cartridge contains all the wetted sealless pump parts (except the casing) and slots in to replace worn or damaged parts without a skilled operative being required. Keeping a cartridge kit in stock is prudent for high value processes that cannot tolerate the expense of maintenance downtime.