Carbon capture technology plays a key role in reducing carbon dioxide emissions, particularly from hard-to-abate sectors. Sundyne has pumps and compressors to support a wide-range of carbon capture technologies, as well as emerging CO2 utilization applications.

To learn more about Sundyne’s value proposition for CCUS, click here to view our CCUS brochure. We have mapped process flow diagrams covering a range of common processes in CCUS and identified where our product portfolio offers superior solutions.

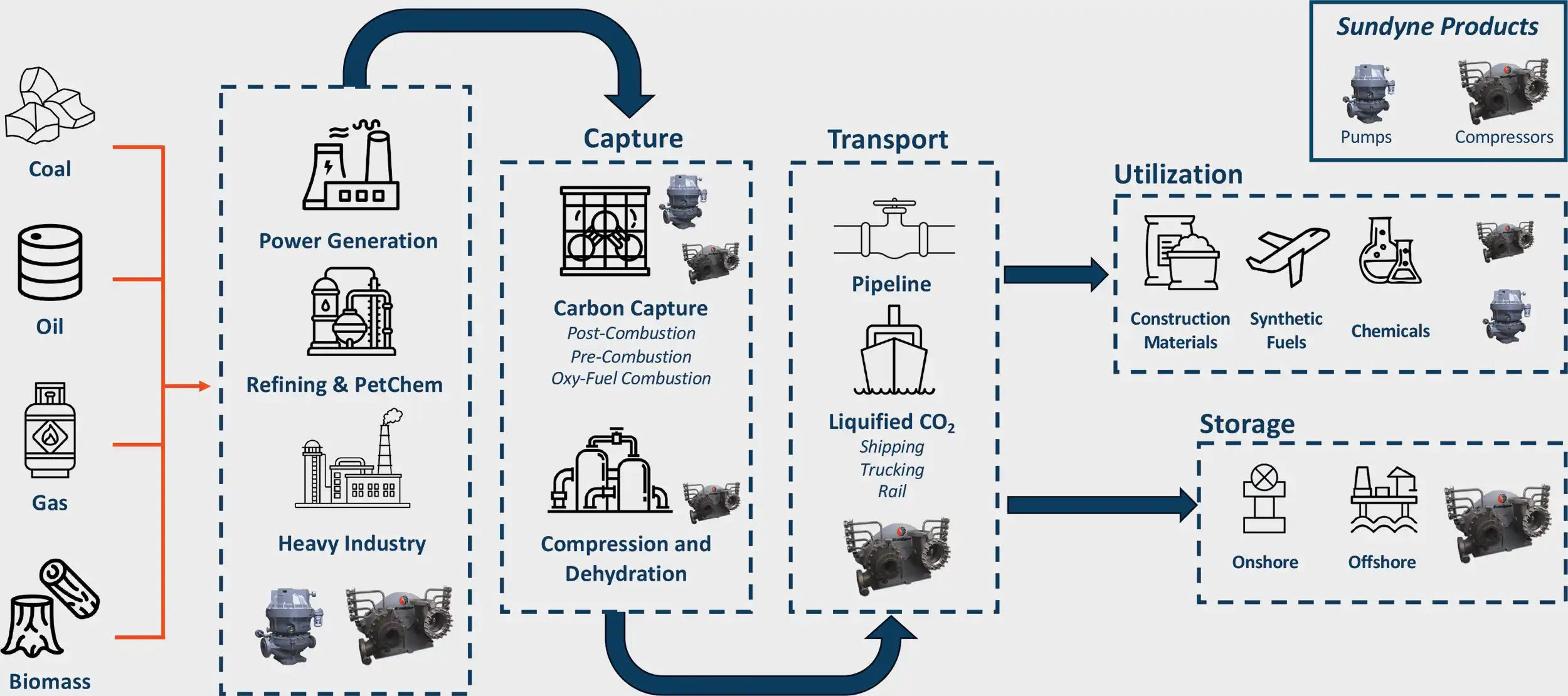

Carbon Capture, Utilization and Storage Value Chain

Sundyne has a range of products that serve the entire CCUS value-chain – including covering a range of carbon capture technologies, compression and dehydration, transportation, utilization, and storage.

Industries and Applications

CCUS has many advantages as a decarbonization solution:

- CCUS technology is ready today and can be scaled to capture CO2 emissions from any size emissions source, including power generation and industrial hard-to-abate emissions.

- CCUS serves processes that use fossil fuels, so it can be deployed in today’s energy mix without requiring new energy sources or production methods to be deployed.

- CCUS is an enabler to blue hydrogen, synthetic fuels production, direct air capture (DAC), and can be paired with biofuels production to produce negative-emissions fuels.

There are multiple carbon capture technologies that exist today. The three main categories are pre-combustion, post-combustion, and oxy-fuel combustion. Sundyne’s product portfolio offers a superior solution to a number of applications within each process.

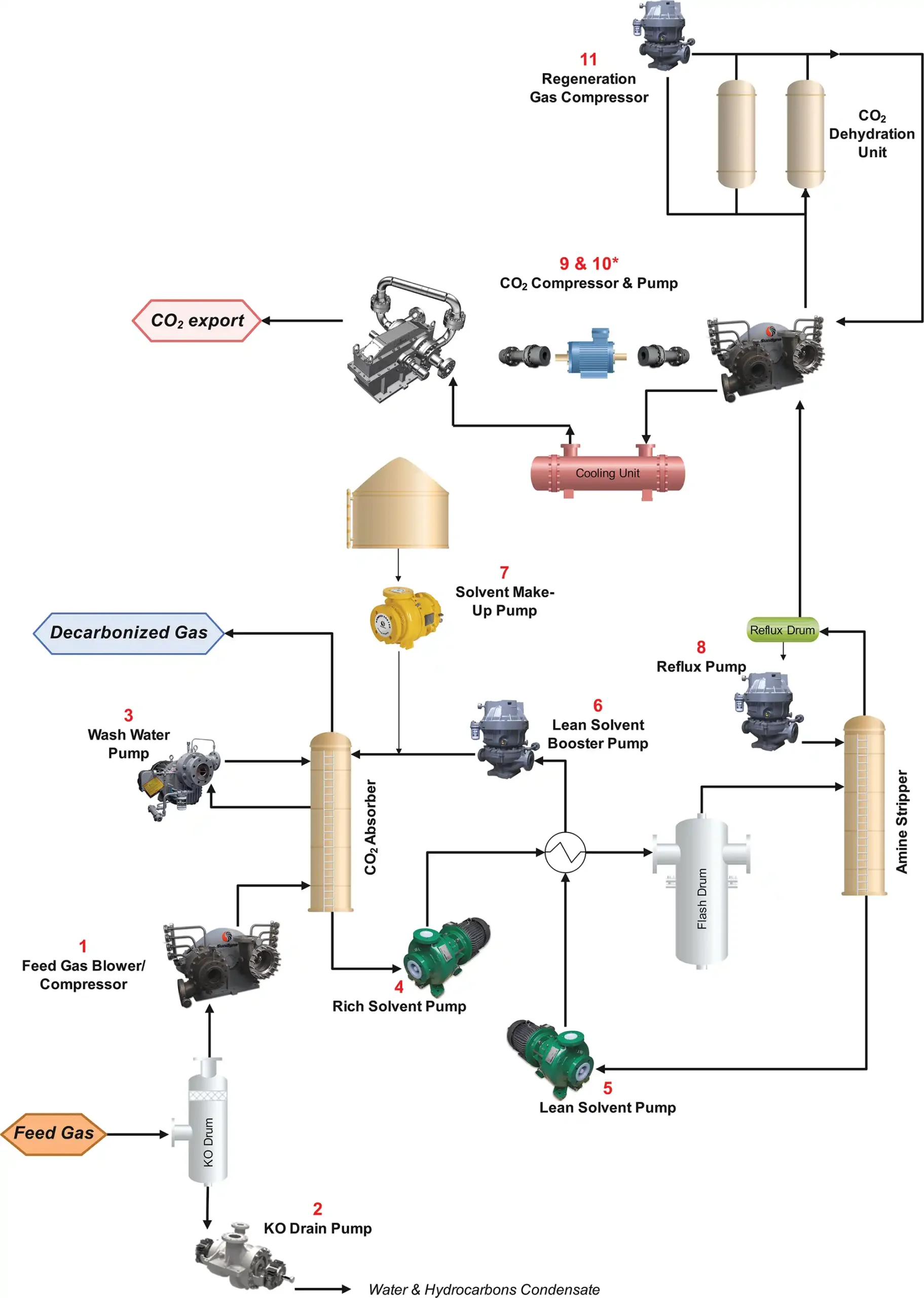

Sundyne Product Fit – Post-Combustion Carbon Capture

Post-combustion carbon capture is the most widely applicable solution today and has been commercially deployed at-scale. Chemical absorption is the most widely used method of CO2 separation within post-combustion capture. Sundyne’s pumps and compressors provide the critical rotating equipment services needed for this process.

Pre-Treatment:

A Gas Blower or Gas Compressor moves the flue gas into a vapor-liquid separator (called a KO, or knockout drum), which removes water and liquid hydrocarbons from the gas stream. The flue gas stream is also cooled prior to being fed into the absorption tower.

Absorption:

The untreated “sour” gas moves into the CO2 absorber. Here, circulation pumps inject aqueous lean amine solutions that bind onto CO2. The treated gas leaving the absorption column is CO2 free and can be released into atmosphere.

Desorption and Regeneration:

The “rich amine” (now containing the CO2) settles at the bottom of the absorber, where it is fed to the regenerator using sealless pumps. The pumps used in this process must be capable of supporting extremely high temperatures. Steam, generated in the reboiler, heats the amine and removes CO2 in the amine stripper. The “lean amine” from the regenerator is cooled in an exchanger, where it is returned to the absorber to be re-used. At the top of the regenerator, the released CO2 is saturated with water. The gas is routed through a reflux drum to condense the water vapor and remove any residual amine, which is then pumped back to the regenerator. The removed CO2 is concentrated and can be sent to a pipeline for sequestration or other utilization end-markets.

| Location | Service | Sundyne Equipment | Medium |

| 1 | Feed Gas Compressor | LF-2000 | Flue Gas |

| 2 | KO Drain Pump | Marelli, LMV | Water, HC Condensate |

| 3 | Wash Water Pump | Marelli, LMV | Water, Amine |

| 4 | Rich Solvent Pump | LMV, HMD, Ansimag, Marelli | Amine + CO2 |

| 5 | Lean Solvent Pump | LMV, HMD, Ansimag, Marelli | Amine |

| 6 | Lean Solvent Booster Pump | LMV, HMD, Ansimag, Marelli | Amine |

| 7 | Solvent Make-Up Pump | LMV, HMD, Marelli | Amine |

| 8 | Reflux Pump | Marelli, LMV | Amine + CO2 |

| 9 | CO2 Compressor* | LF-2000 | Wet CO2, Dry CO2, sCO2 |

| 10 | CO2 Pump* | LMV, HMP, Marelli | Liquid CO2 |

| 11 | Regeneration Gas Compressor | LMC/BMC, LF-2000 | CO2, Water |

* Sundyne offers the unique ability to integrate multiple services within a single machine, including an integrated CO2 pump and CO2 compressor mounted on one skid with one motor. Whenever CO2 is compressed to a supercritical state or whenever CO2 is liquefied then pumped, a dual-service machine guarantees the best integration of process & control management within a compact and modularized arrangement.

For additional process flow diagrams with Sundyne’s product solutions, please reference our CCUS brochure.

Pumps & Compressors for Carbon Capture, Utilization, and Storage

Pumps

- Lean and Rich Solvent Pumps

- Solvent Make-Up Pump

- CO2 Pump

- Reflux Pump

- Wash Water Pump

- Fuel Pump

Compressors

- CO2 Compressor

- N2 and H2 Compressors

- Regeneration Gas Compressor

- HP Flash Gas Compressor

- Feed Gas Compressor

- Recycle Gas Compressor

Recommended Sundyne Equipment

Sundyne’s portfolio of pumps & compressors is specifically designed to address SAF and RD production requirements. For over 60 years, Sundyne has provided pumps and compressors to the refining market. This experience translates to the renewable fuel market. Sundyne’s unique combination of technology, expertise and support provides a 360-degree, full lifecycle service that spans everything from project pre-feed to comprehensive 24×7 support, utilizing a global network of Authorized Service Centers and aftermarket specialists.

Sundyne Compressors

Sundyne’s Integrally-Geared Compressor line features a robust and compact design with an integrated gearbox that runs multiple stages, resulting in space-saving installations. In CCUS applications, efficient and reliable compression of CO2 is critical for the success of projects. Sundyne compressors offer improved efficiency and precise control of operating conditions based on a full scope responsibility including process controls. With modularization of packaged solutions, Sundyne offers reduced lead-times and optimizes the total cost of a compression unit. Sundyne compressors, available from standard to full API compliant configurations, can operate continuously for up to 5 years without requiring maintenance or service.

Sealless Magnetic Drive Pumps – HMD and ANSIMAG

Sundyne sealless pumps provide optimum safety and environmental protection for a wide range of applications in carbon capture and CO2 utilization. They are designed for hazardous and corrosive liquids, and applications that are difficult to seal. HMD Kontro metallic and Ansimag ETFE-lined sealless pumps ensure total product containment, increased reliability and uptime and simplified maintenance with no seals or seal support systems, whilst meeting industry standards such as ASME, ISO and API.

Sundyne LMV and HMP Pumps

Sundyne integrally geared centrifugal pumps are optimized for low flow-high head applications. They offer the best efficiency in the low flow range with a proven track record of high reliability. A single impeller in a Sundyne LMV pump spins at high speed to produce the same head as a multistage pump running at synchronous speed. Sundyne LMV pumps are ideally suited for services such as boiler feed water pumps, condensate pumps, solvent circulation pumps and reflux pumps. To achieve even higher heads, two or more integrally geared stages run in series in Sundyne HMP pumps. Such pumps can be used in liquid CO2 injection applications. The compact design reduces installation cost, and the simplicity limits the number of spare parts while making maintenance easier.

Marelli Pumps

Marelli pumps leverage a track record of more than 60 years in centrifugal pump design, development, manufacturing and service. Marelli caters to global markets from conventional oil & gas and petrochemicals to fast-evolving Clean Energy segments, including green/blue hydrogen, ammonia, carbon capture, and renewable fuels processing. Marelli covers a wide range of API 610 in OH, BB and VS types to meet stringent customer specifications.

Sunflo Pumps

Sundyne Sunflo pumps are fit for purpose, industrial grade pumps designed for Low flow – High head applications, such as boiler feed water, condensate, and demineralized water circulation. The design development of Sunflo range pumps is built on Sundyne knowledge and experience of its API integrally geared pumps. A single impeller runs at high speed to produce high heads in a very compact and reliable design. The close coupled configuration eliminates alignment, simplifies installation while further reducing footprint. The Sunflo cartridge shaft assembly comes complete with all the rotating parts and enables quick and easy servicing of the pump in-place.