For decades, Sundyne has supplied pumps and compressors to refineries worldwide. To satisfy the increasing global demand in Sustainable Aviation Fuel and Renewable Diesel, Sundyne is seamlessly transferring its expertise to the production of these renewable fuels.

To learn more about Sundyne’s value proposition for SAF and Renewable Diesel production, click here.

Industries & Applications:

Sustainable Aviation Fuel – SAF

Sustainable Aviation Fuel, made from non-petroleum feedstocks, is an alternative fuel that reduces emissions caused by air transportation. Non-petroleum renewable feedstocks used to produce SAF include food crops, municipal waste, woody biomass and fats/greases/oils. Currently ASTM approved SAF can be blended at different levels with limits of 5% to 50%, depending on the feedstock and how the fuel is produced.

Renewable Diesel – RD

Renewable Diesel, also known as Green Diesel, is a replacement for diesel. It can be used to fully replace diesel, or it can be blended with diesel.

RD & SAF production uses the same hydrotreating and separation processes used for petroleum derivatives fuels, therefore, it employs the same basic infrastructure and equipment. Many conventional refineries have chosen to convert to SAF & RD production or add renewable fuel units. Several grassroot plants have been built, solely dedicated to the production of SAF & RD.

Multiple Production Pathways

Several pathways have been developed to produce SAF & RD, including Hydro-processed Esters and Fatty Acids (HEFA) and Alcohol-to-Jet fuel (ATJ). HEFA is fully commercialized while ATJ is making great strides with promising pilot plants and near-term commercial facilities.

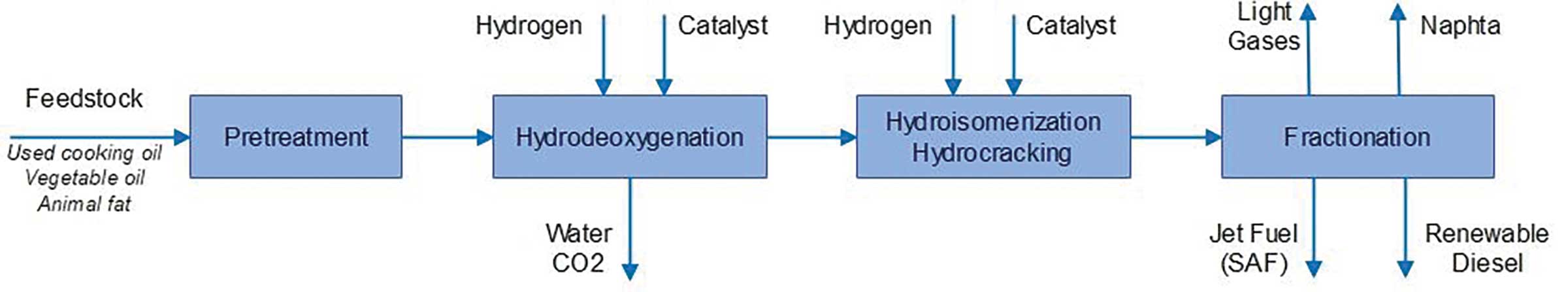

Hydro-processed Esters and Fatty Acids (HEFA) Jet Fuels

Any type of oil, such as animal fat, waste grease, vegetable oil or algae can be hydrogenated and isomerized to produce long-chain hydrocarbons. An additional selective cracking process yields sustainable aviation fuel. SAF & RD production use the same hydrotreating and separation processes that are used for petroleum diesel, and they employ the same basic infrastructure and equipment.

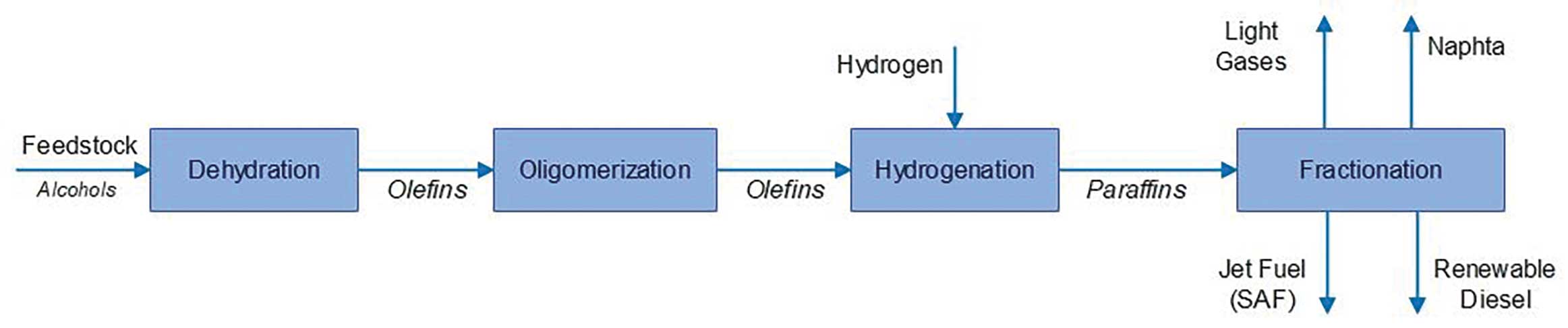

Alcohol-to-Jet (ATJ)

The Alcohol-to-Jet pathway utilizes alcohol as a source (either Iso-butanol or Ethanol) for the production of SAF & RD. The Alcohol can be produced from sugary, starchy and biomass feedstocks. ATJ converts alcohols into SAF & RD by removing the water (Dehydration) and linking the molecules together to get the desired carbon chain length (i.e., Oligomerization). Further processing includes Hydrogenation and Fractionation to get the SAF & RD.

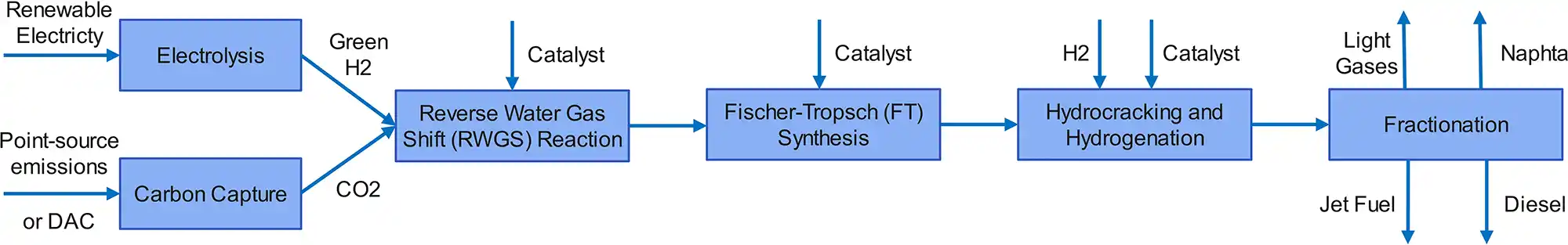

Fischer-Tropsch (FT) Synthesis or Power-to-Liquid (PtL) SAF

The Fischer-Tropsch synthesis pathway uses a syngas or a hydrogen source, along with carbon monoxide or dioxide as a feedstock, to produce SAF & RD. The syngas can be produced via biomass gasification, or a more pure hydrogen stream can be used as a feedstock. If green hydrogen is used, then the SAF is termed “Power-to-Liquid”. A Reverse Water-Gas Shift (RWGS) reaction can be used to convert the CO2 into CO, and then a Fischer-Tropsch synthesis reaction is used to convert the syngas (H2 + CO) into liquid hydrocarbons.

Pumps & Compressors for SAF and RD Production

Pumps

Feed Pumps

Reflux Pumps

Bottoms Pumps

Overhead Pumps

Product Pumps

Reactor Feed Pumps

Reactor Recycle Pumps

Amine Solution Pumps

Pumps

Drain Pumps

Slop Pumps

Water Feed Pumps

Caustic Pumps

Citric Acid Pumps

Boiler Feed Water Pumps

Condensate Pumps

KO Drum Pumps

Compressors

H2 Make-up Compressor

Hydrogen Storage Compressor

Recycle Gas Compressor

Oligomerization Flash Gas Recycle Compressor

Refrigerant Gas Compressor

Recommended Sundyne Equipment

Sundyne’s portfolio of pumps & compressors is specifically designed to address SAF and RD production requirements. For over 60 years, Sundyne has provided pumps and compressors to the refining market. This experience translates to the renewable fuel market. Sundyne’s unique combination of technology, expertise and support provides a 360-degree, full lifecycle service that spans everything from project pre-feed to comprehensive 24×7 support, utilizing a global network of Authorized Service Centers and aftermarket specialists.

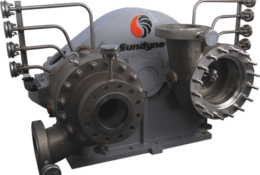

Sundyne Integrally-Geared Pumps

Sundyne integrally geared pumps are optimized for low flow-high head applications. Applications such as charge, reflux and overhead are ideally suited for Sundyne LMV pumps. Other services include boiler feed water pumps and high-pressure washing water pumps. The single impeller running at high speed produces the same head as multistage pumps running at synchronous speed. The compact and simple design reduces installation cost and the number of spare parts, making maintenance easier. Sundyne LMV pumps have the added benefit of offering the highest efficiency in the low flow range.

Marelli Pumps

Marelli pumps leverage a track record of more than 60 years in centrifugal pump design, development, manufacturing and service, to fulfill the latest standards for oil & gas, petrochemical and green markets. SAF/RD production requires a variety of API 610 pumps. Marelli pumps are designed for extreme reliability and a wide range of flow rates, to accommodate the most stringent customer specifications.

Sundyne Sealless Pumps – HMD and ANSIMAG

Sundyne has been the market leader in sealless magnetic drive pump technology for several decades. Sundyne HMD Kontro metallic and Ansimag lined sealless pumps offer total product containment in a simple, compact design. These pumps handle harsh, hazardous and corrosive liquids and other difficult to seal applications within SAF/RD production with increased reliability, minimized maintenance and the highest levels of safety. Helping to minimize energy consumption, Sundyne HMD Kontro sealless pumps are available with the non-metallic ZeroLoss containment shell that eliminates magnetic coupling losses and in turn increases energy efficiency and reliability when handling heat sensitive liquids. All Sundyne sealless pumps operate without the need for complicated seal support systems and deliver the lowest total cost of ownership across ANSI, ISO and API platforms.

PPI Diaphragm Compressors

Sundyne enables organizations to deliver Net-Zero through sustainable, safe and environmentally conscious compression solutions with the broad portfolio of advanced Hydrogen compressors and packages renowned for highly reliable, leak-free performance that deliver the critical non-contaminating compression of Hydrogen required for the production of SAF. Aftermarket support for PPI Diaphragm compressors is provided via Sundyne’s global network of channel partners.

Sundyne Integrally-Geared Compressors

Sundyne Integrally-Geared Compressor line features a robust and compact design with an integrated gearbox that runs multiple stages, resulting in space-saving installations. In the refining industry, where process optimization and control are critical, Sundyne compressors offer improved efficiency and precise control of operating conditions. Sundyne integrally-geared small to medium size compressors provide a superior solution, particularly for applications such as Hydrogen Compressors or Recycle Gas Compressors that involve compressing low molecular weight gases.

Sundyne compressors, available from standard to full API compliant configurations, can operate continuously for up to 5 years without requiring maintenance or service. With easy access to internal components like impellers and bearings, maintenance downtime and cost are significantly reduced.