What is SAF (Sustainable Aviation Fuel)?

Sustainable Aviation Fuel, made from non-petroleum feedstocks, is a drop-in alternative fuel that reduces emissions caused by air transportation. Non-petroleum renewable feedstocks include the food and yard waste portion of municipal solid waste, woody biomass, fats, greases and oils. Currently, ASTM-approved SAF can be blended at different levels between 5% and 50%, depending on the feedstock and how the fuel is produced.

What is Renewable Diesel (RD)?

Renewable Diesel, also known as Green Diesel, is a replacement for conventional diesel. It can be used to fully replace diesel or blended with any amount.

RD & SAF production uses the same hydrotreating and separation processes used for petroleum diesel, therefore, it employs the same basic infrastructure and equipment. Many conventional refineries have chosen to convert to SAF & RD production or add renewable fuel units. Several grassroot plants have been built, solely dedicated to the production of SAF & RD.

Multiple Pathways

Several pathways have been developed to produce SAF & RD, including Hydro-processed Esters and Fatty Acids (HEFA) and Alcohol-to-Jet fuel (ATJ). HEFA is fully commercialized while ATJ is making great strides with promising pilot plants and near-term commercial facilities.

-

- Hydro-processed Esters and Fatty Acids (HEFA) jet fuel:

Any type of oil, such as animal fat, waste grease, vegetable oil or algae can be hydrogenated and isomerized to produce long-chain hydrocarbons. An additional selective cracking process yields sustainable aviation fuel. SAF & RD production use the same hydrotreating and separation processes that are used for petroleum diesel, and they employ the same basic infrastructure and equipment. - Alcohol-to-Jet (ATJ):

The Alcohol-to-Jet pathway utilizes alcohol as a source (either Iso-butanol or Ethanol) for the production of SAF & RD. The Alcohol can be produced from sugary, starchy and biomass feedstocks. ATJ converts alcohols into SAF & RD by removing the water (Dehydration) and linking the molecules together to get the desired carbon chain length (i.e., Oligomerization). Further processing includes Hydrogenation and Fractionation to get the SAF & RD.

- Hydro-processed Esters and Fatty Acids (HEFA) jet fuel:

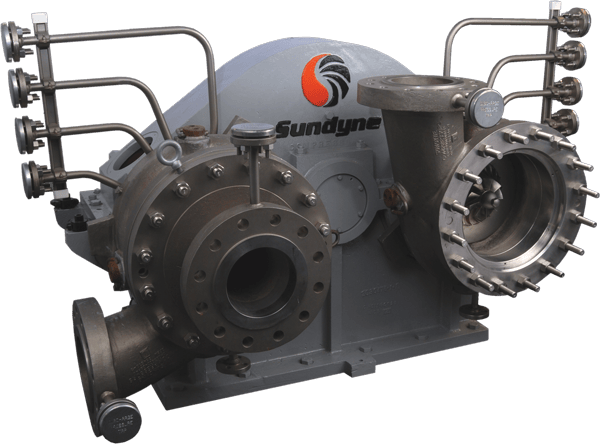

Sundyne Pumps and Compressors:

Relying on decades of experience, gained at thousands of references in conventional petroleum refineries, Sundyne pumps and compressors are ideally suited for the production of renewable fuels.

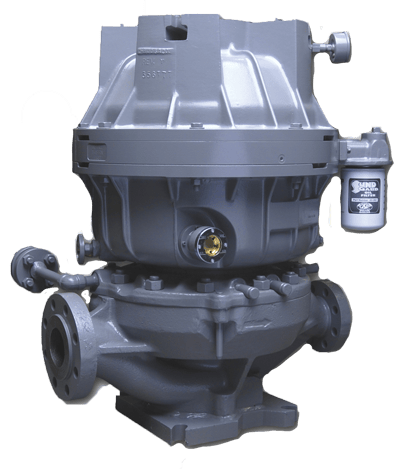

Sundyne Integrally Geared Pumps:

Sundyne OH6 pumps are optimized for low flow-high head applications, such as reactor charge pumps, reflux pumps, overhead pumps, high pressure washing water pumps and bottoms pumps. The single stage pumps running at greater than synchronous speed offer the highest efficiency available, as well as robustness, reliability, ease of maintenance and ease of rerates. The compact design, compared to multistage pumps running at synchronous speed, reduces installation costs and the number of spare parts needed.

Sundyne Marelli:

API 610 pumps are widely used throughout the SAF & RD plants. OH2, BB2, BB3, VS1, VS4 models offer superior reliability and compliance with the latest revision of the API 610 standard. Marelli pumps accommodate the most stringent customer specifications.

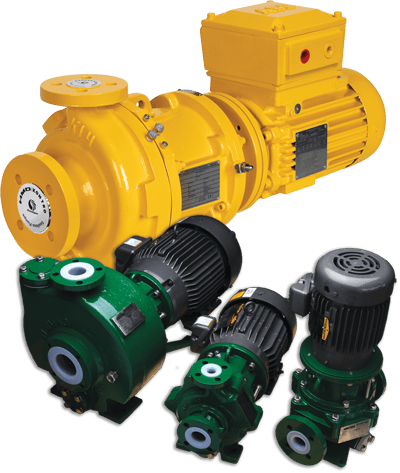

Sundyne HMD and Ansimag Pumps:

Sundyne has been the market leader in sealless magnetic drive pump technology for several decades. Sundyne HMD metallic and Ansimag lined sealless pumps offer total product containment in a simple, compact design. These pumps handle harsh, hazardous and corrosive liquids, as well as other difficult-to-seal applications, with increased reliability, minimized maintenance and the highest levels of safety.

Sundyne Integrally Geared Compressors:

Sundyne integrally geared compressors feature single or multiple stage configurations. The robust and compact design results in space-saving installations. In the refining industry where process optimization and control are critical, Sundyne compressors offer improved efficiency and precise control of operating conditions. They are well suited for hydrogen compressors and recycle gas compressors that involve compressing low molecular weight gases.

Sundyne PPI Diaphragm Compressors

Sundyne enables organizations to deliver Net-Zero through sustainable, safe and environmentally conscious compression solutions. Sundyne’s broad portfolio of advanced Hydrogen compressors and packages are renowned for highly reliable, leak-free performance that delivers non-contaminating Hydrogen compression for SAF production. Aftermarket support for PPI Diaphragm compressors is provided via Sundyne’s global network of channel partners.

In Summary:

Sundyne’s complete portfolio of centrifugal pumps, centrifugal and diaphragm compressors offers a complete solution for your rotating equipment needs in sustainable aviation and renewable diesel plants. Over 70 years of experience, countless references and exceptional service capability make Sundyne the number one partner for the reliable operation of your renewable fuel plant. To learn more, Contact Sundyne Today.