Upgrade Improves Reliability, Reduces Downtime, Enhances Performance and Decreases Maintenance Intervals

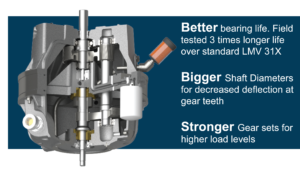

Arvada, Colorado: August 17, 2020 – Sundyne, a global leader in the design and manufacture of API compliant pumps and compressors for the oil & gas, refining, power generation, chemical and water treatment industries, today announced a simple upgrade for LMV 31X pumps with the introduction of the LMV 33XN Gearbox Conversion. The new LMV-33XN gearbox features a robust design that is capable of handling higher loads and tougher process conditions, while also extending mean time between maintenance intervals.

This new upgrade is offered as an easy, interchangeable, bolt-on solution that can be delivered to customer sites quickly. Sundyne’s LMV 31X pumps have been deployed for decades – and this upgrade targets existing LMV 31X pumps that are approaching an overhaul, or for units that are not meeting newly expanded MBTM expectations.

“Process conditions in plants serving the energy, chemical and power industries are changing, and every operator seeks greater efficiency, better reliability and decreased maintenance costs via extended MBTM intervals,” said Sundyne’s Aftermarket Product Manager Donald de Regnier. “Our new gearbox upgrade provides a bigger idler shaft with stronger gear sets that can handle higher loads, and it also extends the bearing life three-times longer than the existing LMV 31X offering.”

Sundyne’s new gearbox upgrade offers the following ten improvements:

- Enhanced labyrinth/face input shaft seal – reduces oil misting, shaft wear and gearbox contamination.

- Improved spherical roller bearings (idler shaft) – the L10 bearing life of 25,000 hours at rated point is three times greater than the bearings used in a 31X gearbox. This upgraded design provides significantly higher radial and axial loading capacity.

- New helical upper mesh gears – handle the highest levels of loading in the entire gearbox. The new helical teeth provide 3 points of contact at all times (as opposed to straight teeth with one point of continuous contact). This 59% increase in gear thickness significantly increases the load capacity over a 31X gearbox.

- New bolt-in, unidirectional internal lube pump – increases capacity to provide 12% more oil flow.

- Improved oil fill & reserves – ensures lubrication of thrust and journal bearings prior to start up.

- No auxiliary lube pump is required – for more than 90% of applications.

- Increased shaft diameter – offers greater load capacity and decreased deflection at gear teeth.

- Lower mesh gears – are now 49% thicker than LMV-311 for increased load handling.

- Lower idler bearing – new hydrodynamic bearings improve life & load capacity.

- Splined impeller connection – provides superior torque distribution to combat shaft fatigue.

The new LMV 33XN conversion is eligible for Sundyne’s gearbox exchange program. Anyone interested in learning more should GO HERE. For more information on Sundyne’s products and aftermarket services, please visit www.sundyne.com.

About Sundyne:

Headquartered in Arvada, Colorado with operations and presence in Europe, the Middle East, India, Asia, Japan and China, Sundyne is a leading manufacturer of precision-engineered highly reliable, safe, and efficient centrifugal pumps and compressors for use in hydrocarbon processing, chemical processing, power generation, industrial, and high-pressure water applications. Sundyne is the world leader in delivering low-flow, high-head integrally geared centrifugal pumps and compressors as well as a leader in the supply of safe and leakage-free sealless magnetic drive centrifugal pumps and diaphragm compressors. Sundyne pump and compressor designs are compliant with the industry’s most stringent API, ANSI/ASME, and ISO standards. To learn more about the Sundyne family of precision-engineered pumps and compressors, please visit www.sundyne.com.

Contact:

Mike Dean

303-521-5713

mike.dean@sundyne.com