Reliable high pressure pumps handle high suction pressure H2S

Sour Water

Wastewater that is produced from atmospheric and vacuum crude columns at refineries. Hydrogen sulfide and ammonia are typical components in sour water that need to be removed before the water can be reused elsewhere in the plant. Removal of these components is done by sending the sour water from the process to a stripping tower where heat, in the form of steam, is applied. The ammonia and hydrogen sulfide contained in the water is released by the heat and exits the top of the tower. Sundyne pumps are especially suited to handling wastewater at high pressure required to send liquids through the stripping tower.

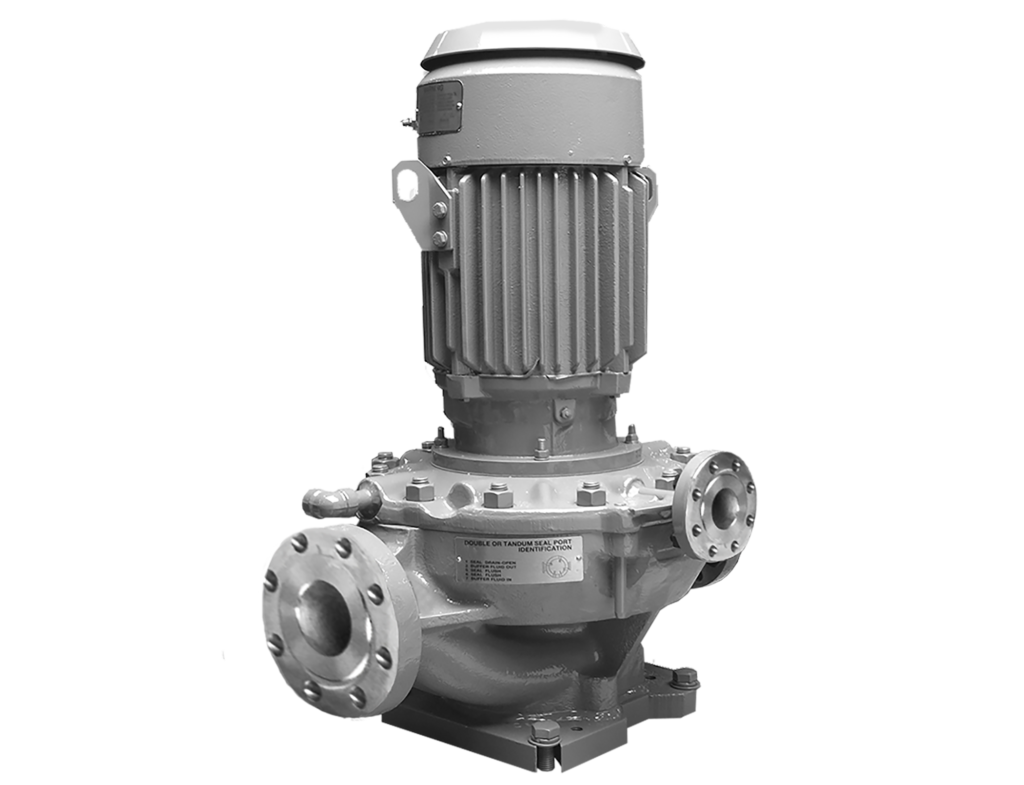

Sundyne Direct Drive Pumps

The Sundyne API 610, direct drive family of pumps are vertical inline, single stage, overhung pumps that are either a close coupled design (OH5) or features a separate bearing bracket (OH3) with a flexible shaft coupling to accommodate multiple motor options. Space saving vertical designs and exceptional reliability make Sundyne direct drive pumps perfect for offshore applications.

Sundyne Integrally Geared Pumps

Sundyne API 610, OH6 Integrally Gear Driven Pumps are engineered for critical high-head, low-flow, heavy-duty services required for upstream offshore oil and gas production.

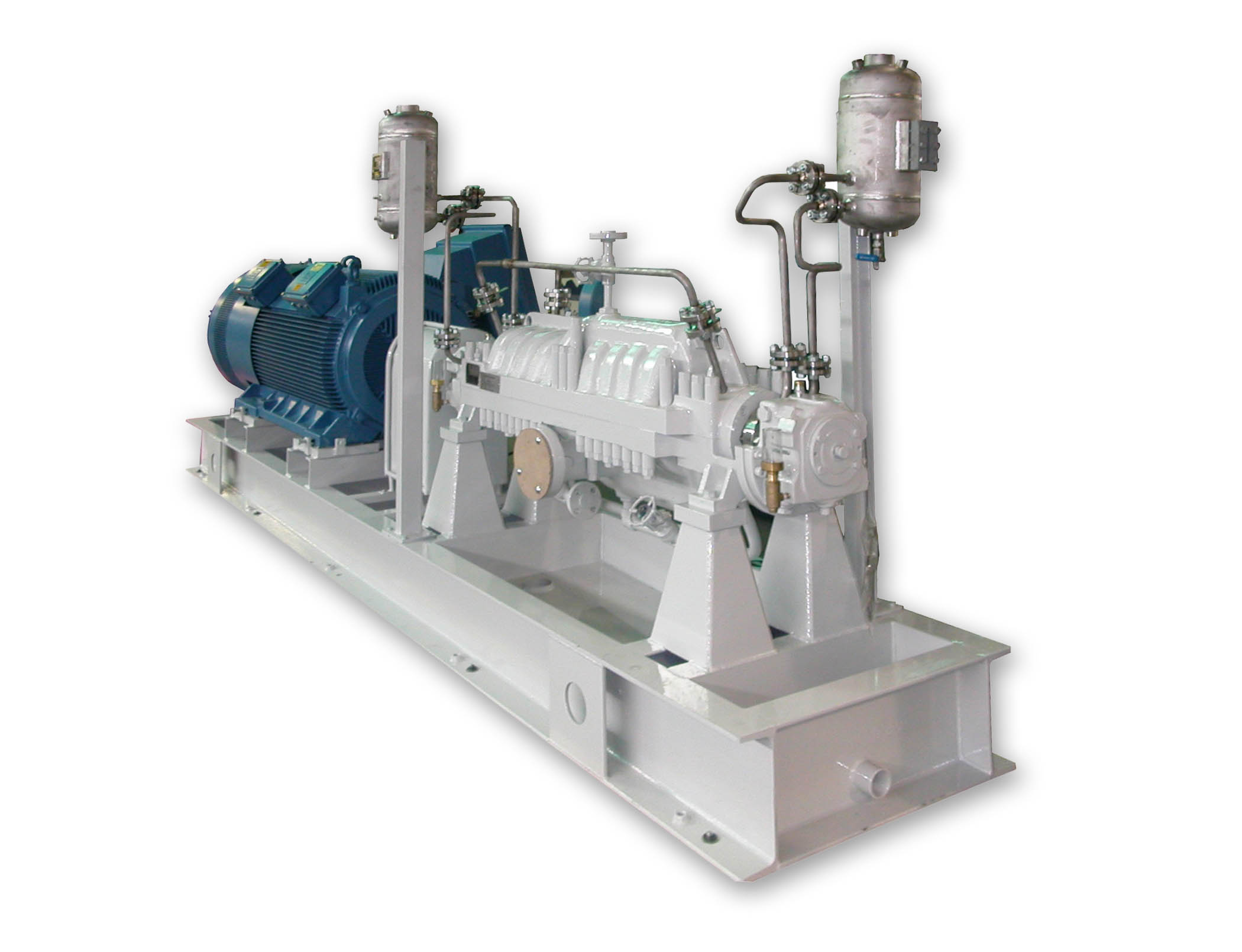

Marelli Heavy Duty API 610 Process Pumps

Highly reliable with a long life, Marelli multi-stage pumps are capable of reaching massive flow rates and pressures. They are ruggedly designed to run continuously for years with rugged rotor designs and low vibration balanced rotor designs. They are efficiently designed to save energy and meet exacting API 610 and ISO 13709 standard requirements for overhung, between-bearings and vertically-suspended centrifugal pumps.