High pressure pumps and compressors for visbreaking

Visbreaking

Thermal non–catalytic process used to convert large hydrocarbon molecules in heavy feedstocks to lighter products such as fuel gas, gasoline, naphtha and gas oil. Produces sufficient middle distillates to reduce the viscosity of the heavy feed. A visbreaker thermally cracks large hydrocarbon molecules in the oil by heating in a furnace to reduce its viscosity and to produce small quantities of light hydrocarbons (LPG and gasoline). The process name of visbreaker refers to the fact that the process reduces or breaks the viscosity of the residual oil.

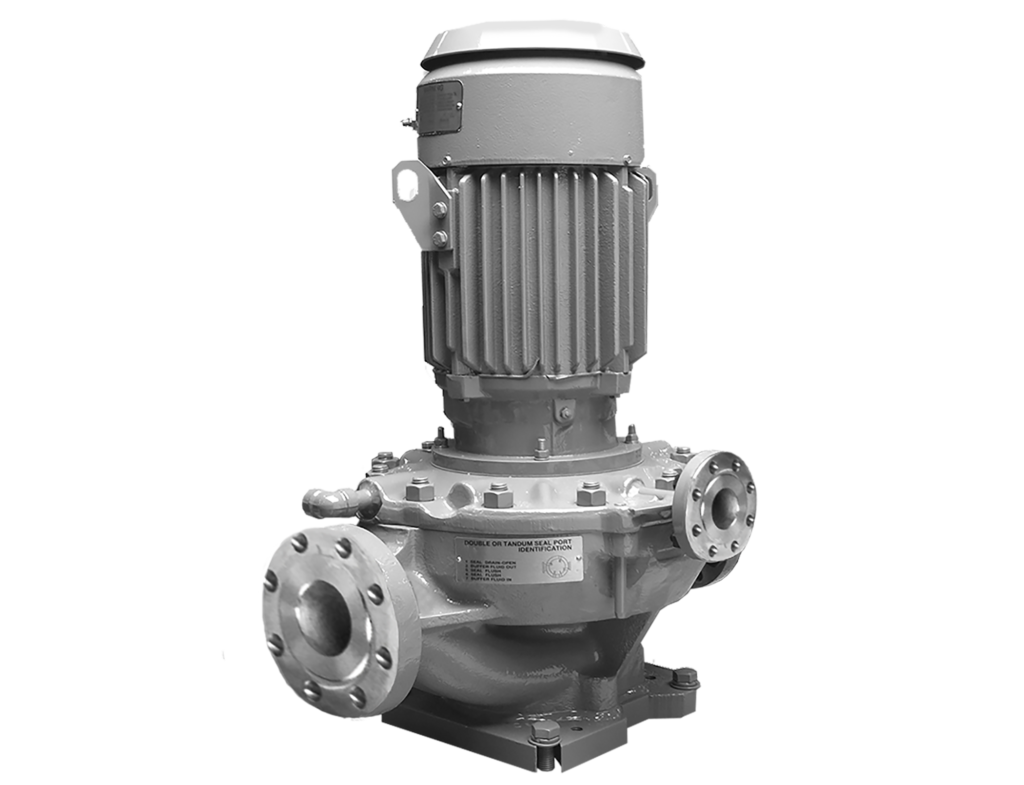

Sundyne Direct Drive Pumps

The Sundyne API 610, direct drive family of pumps are vertical inline, single stage, overhung pumps that are either a close coupled design (OH5) or features a separate bearing bracket (OH3) with a flexible shaft coupling to accommodate multiple motor options. Space saving vertical designs and exceptional reliability make Sundyne direct drive pumps perfect for offshore applications.

Sundyne Integrally Geared Pumps

Sundyne API 610, OH6 Integrally Gear Driven Pumps are engineered for critical high-head, low-flow, heavy-duty services required for upstream offshore oil and gas production.

HMD/Kontro Sealless Magnetic Drive Pumps

HMD/Kontro sealless magnetic drive designs are an alternative to traditional sealed pumps. Sealless magnetic drive pumps present absolutely no risk of emissions or leaks, which can harm productivity, personnel and the environment. Built to API 685 standards, these pumps are safe and low maintenance for offshore applications.

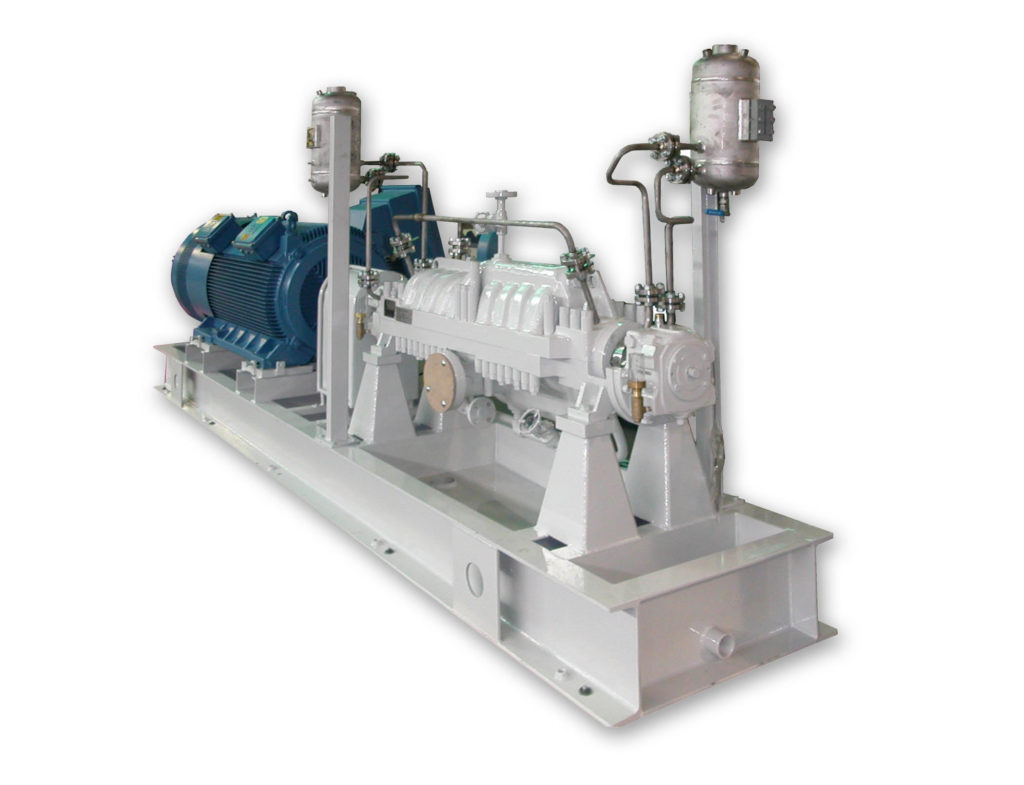

Marelli Heavy Duty API 610 Process Pumps

Highly reliable with a long life, Marelli multi-stage pumps are capable of reaching massive flow rates and pressures. They are ruggedly designed to run continuously for years with rugged rotor designs and low vibration balanced rotor designs. They are efficiently designed to save energy and meet exacting API 610 and ISO 13709 standard requirements for overhung, between-bearings and vertically-suspended centrifugal pumps.

Sundyne Process Gas Compressors

Single- and multi-stage centrifugal designs meet API 617 standards applications for handling offshore injection, scrubbing, process gas, dehydration, regeneration, H2S removal, flare, vent and fuel gas applications. Each model is custom built to provide pulsation- and vibration-free operation, and to deliver oil-free process gas with zero emissions. NACE compliant Sundyne compressors do not rust or corrode. Each unit is engineered in accordance with industry standards, and is designed to run continuously for 5 to 7 years without the need for costly maintenance or over-hauls.