Designed for processes engineers requiring reliable operation in the full range of high pressure services

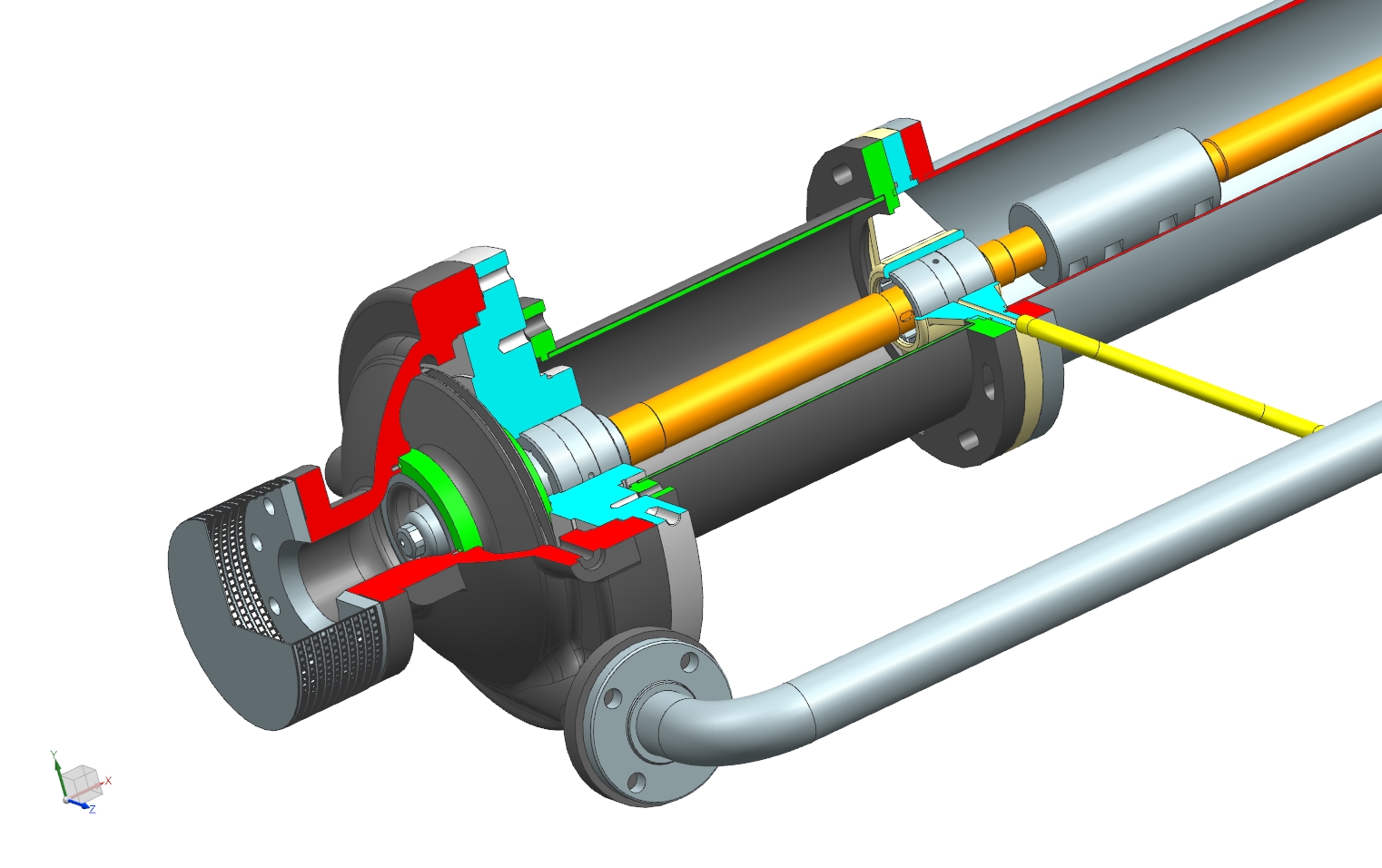

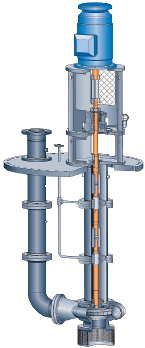

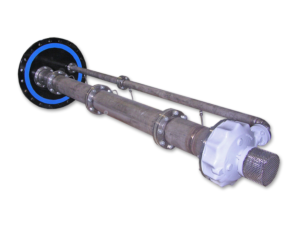

The Marelli VSMK VS4 type sump pump series are vertical process pumps, single volute, radial split, self-venting, vertical split casing and single stage. Developed for the medium-pressure movement of water, hydrocarbon, CO2 and other process liquids, our solutions meet the most stringent customer specifications.

- Flows to 7,000 gpm (1,600 m³/hr)

- Heads to 1,180 ft (360 m)

- Suction Pressure: Flooded

- Temperature Range -22 to 752°F (-30 to 400°C)

APPLICATIONS

- Refineries

- Desalination plants

- Process charge

- API basins

- Condensate extraction

- Tank farms

- Tanks fluid transfer

- Petrochemical plants

- Fertilizers

- Oil fields and terminals

- Offshore and onshore petroleum and gas

- Reverse osmosis

- Synfuels

- Paper mills

- Pharmaceutical industry

Marelli has more than 50 years of experience in centrifugal pump design, development, manufacturing and service, to fulfill the latest standards for the petroleum, petrochemical, and heavy duty processing industries.

- Fully compliant API-610 11th Edition/ISO 13709

- All VS4 series pumps are suitable for 50 Hz and 60 Hz operation

- Higher efficiencies

- Labyrinth bearing seals to avoid external contamination and maximize seal/lubrication life

- API-682, 3rd edition mechanical seal chamber. Also complies with API-610 standards

- Choice of multiple impellers in each hydraulic pump casing for optimum efficiency

- Instrumentation options available

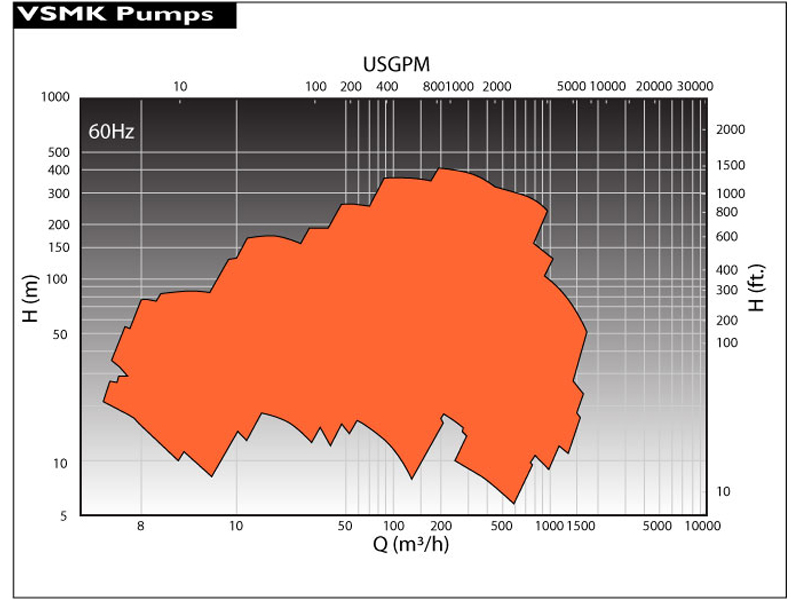

US 60 Hz

- Heads to 1,180 ft

- Flows to 7,000 gpm

- Standards API 610 VS4

- Maximum Motor Power 939 HP

- Temperature Range -22 to 752°F

- Maximum Case Working Pressure 580 psi

- Maximum Suction Pressure Flooded

- Differential Head 820 ft

- Maximum Viscosity Consult Factory

- Mounting Configuration Submersible Vertical

- Seal Configurations API 682

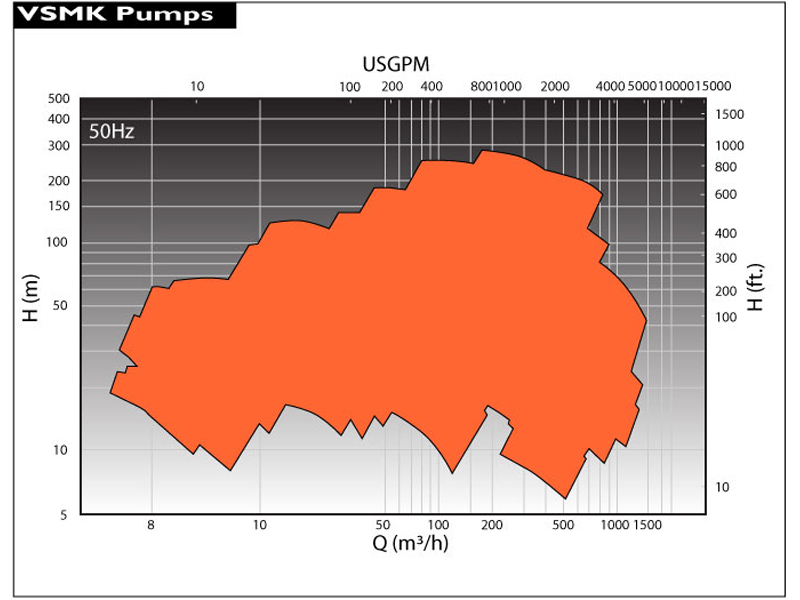

Metric 50 Hz

- Heads to 360 m

- Flows to 1,600 m3/hr

- Standards ISO 13709

- Maximum Motor Power 700 kW

- Temperature Range -30 to 400°C

- Maximum Case Working Pressure 40 bar

- Maximum Suction Pressure Flooded

- Differential Head 250 m

- Maximum Viscosity Consult factory

- Mounting Configuration Submersible Vertical

- Seal Configurations API 682

| Part | S1 | S5 | S6 | S8 | C6 | A8 | D1 |

| Pressure Casing | Carbon Steel (A216 WCB) | 12% CHR | 316 AUS | Duplex | |||

| Impeller | Cast Iron | Carbon Steel | 12% CHR | 316 AUS | 12% CHR | 316 AUS | Duplex |

| Wear Rings | Cast Iron | 12% CHR Hardened | Hard-faced 316 AUS | 12% CHR Hardened | Hard-faced 316 AUS | Hard-faced Duplex | |

| Shaft | Carbon Steel | AISI 4140 | 316 AUS | 12% CHR | 316 AUS | Duplex | |

| Bearing Housing | Carbon Steel (A216 WCB) | ||||||

| Base Gasket | AUS, Spiral Wound | 316 AUS Spiral Wound | AUS, Spiral Wound | 316 AUS, Spiral Wound | Duplex SS Spiral Wound | ||