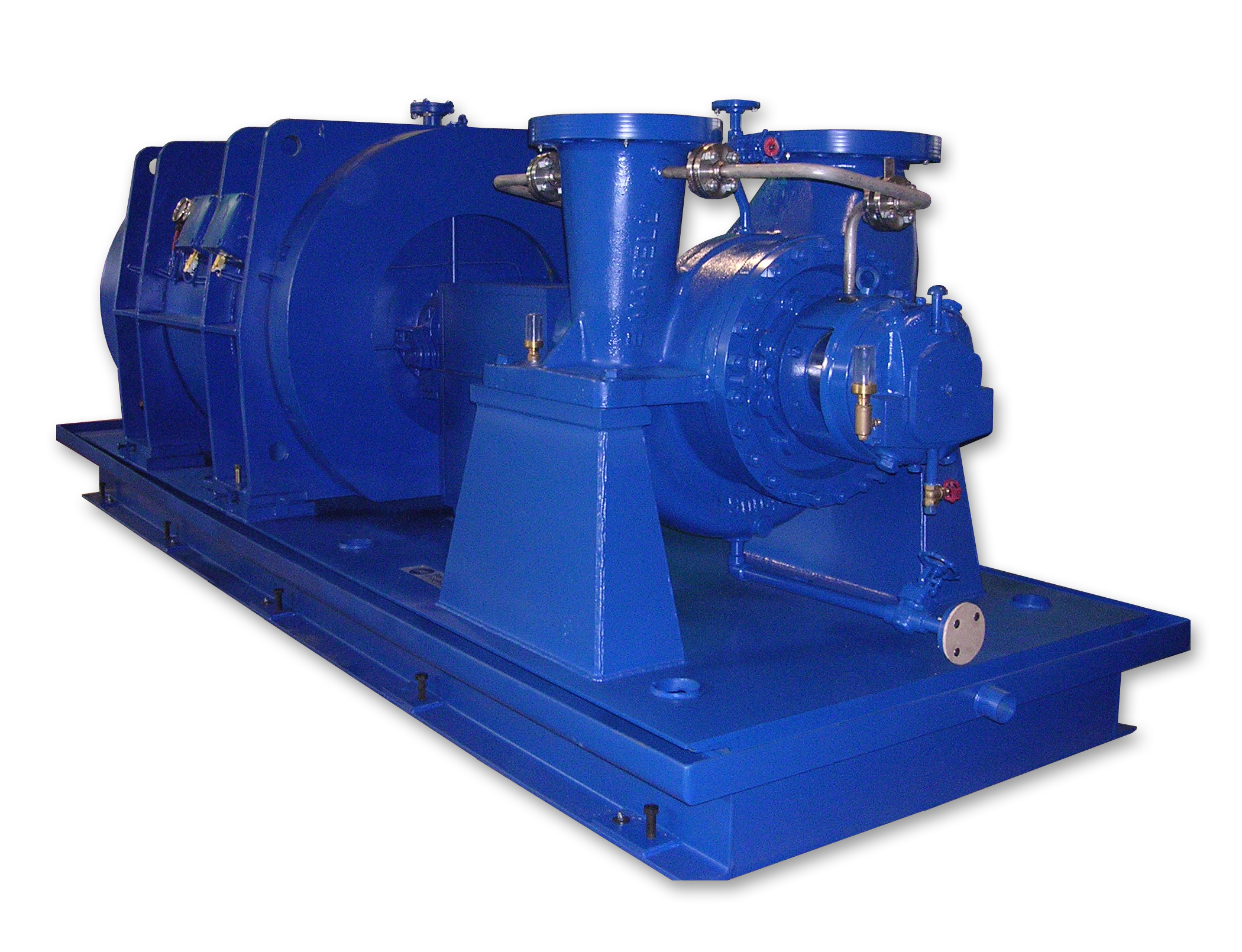

Designed for processes engineers requiring reliable operation in heavy-duty elevated temperature process services

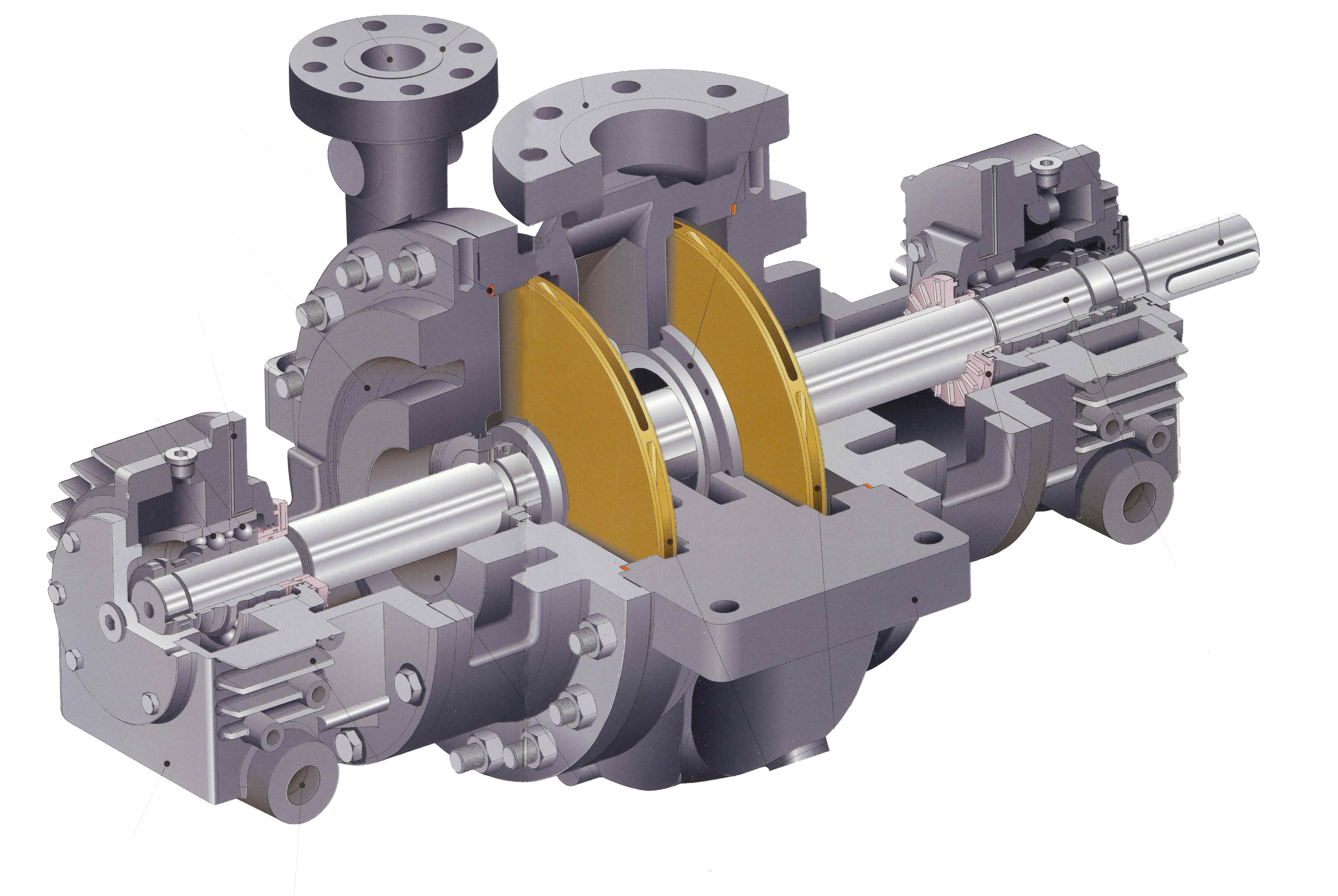

The Marelli model KSMK, API 610 BB2 and ISO 13709 radially split, centerline mounted, double volute, between-bearings centrifugal process pump. It is available in one or two stage configurations. These pumps feature a double suction impeller. In-line and side by side flange configurations are available.

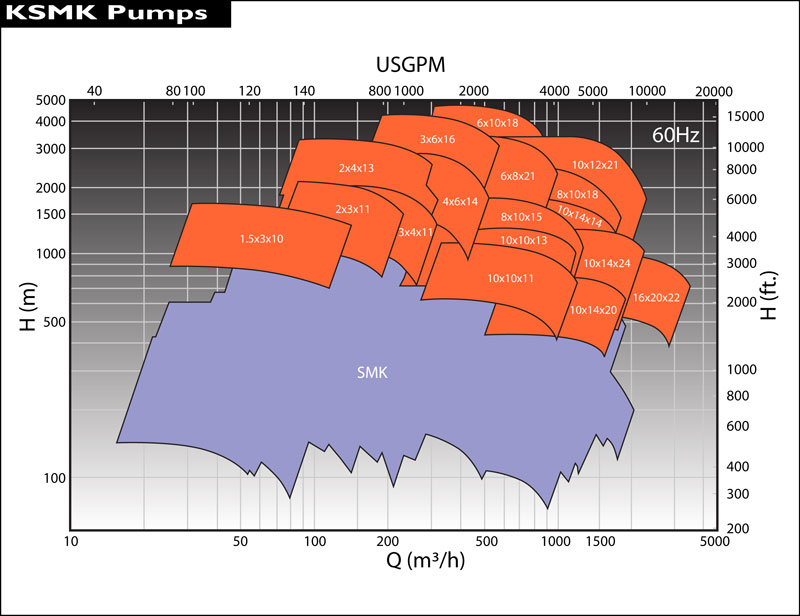

- Flows to 13,208 gpm (2,400 m³/hr)

- Heads to 1,640 ft (350 m)

- Suction Pressure 290 psi (20 bar)

- Temperature Range -22 to 752°F (-30 to 400°C)

Precision engineered API/ISO 13709 process pumps meeting rigorous engineering requirements for heavy duty, high temperature applications while receding the total life cycle cost and improving mean time between repairs.

APPLICATIONS

- Toppings

- Gas condensate

- HDS

- Platforming

- Thermal solar

- crude oil pipelines

- Gas pipelines

- Charge pumps

- Low shear applications

Proven to be reliable, efficient and long-lasting, Marelli BB2 pumps provide a number of operational benefits for process engineers and plant operators:

- API 610 11th Edition/ISO 13709 full compliance for reliability and accountability

- Suitable with 60 Hz and 50 kW motors

- Choice of multiple impellers in each hydraulic pump casing for maximum efficiency over a wide operating range

- Centerline mounted pump casing maintains alignment during operation at elevated temperatures

- Low suction specific speed and low NPSH characteristics, with a wide choice of impellers for optimum efficiency over a large operating range

- Finned bearing housing to provide maximum heat dissipation under API 610 compliance

- Deflection system with fins to improve cooling

- Labyrinth bearing seals to avoid external contamination and maximize seal and lubrication life

- Highly maintainable and replaceable wear rings to reduce overall life cycle costs

- Mechanical seal chamber suitable for cartridges defined under API 682 3rd Edition

- Socket welded flanged drains and vents as standard. Gussets and bracing also available

- A variety of instrumentation options are available for monitoring all key operating parameters (temperature, pressure, vibrations and more)

US 60 Hz

- Heads to 1,640 ft

- Flows to 13,208 gpm

- Standards API 610 BB2

- Maximum Motor Power 2,000 HP

- Temperature Range -22 to 752°F

- Maximum Case Working Pressure 870 psi

- Maximum Suction Pressure 290 psi

- Differential Head 1,640 ft

- Maximum Viscosity Consult Factory

- Mounting Configuration Horizontal/Top-Top (optional side-side)

- Seal Configurations API 682

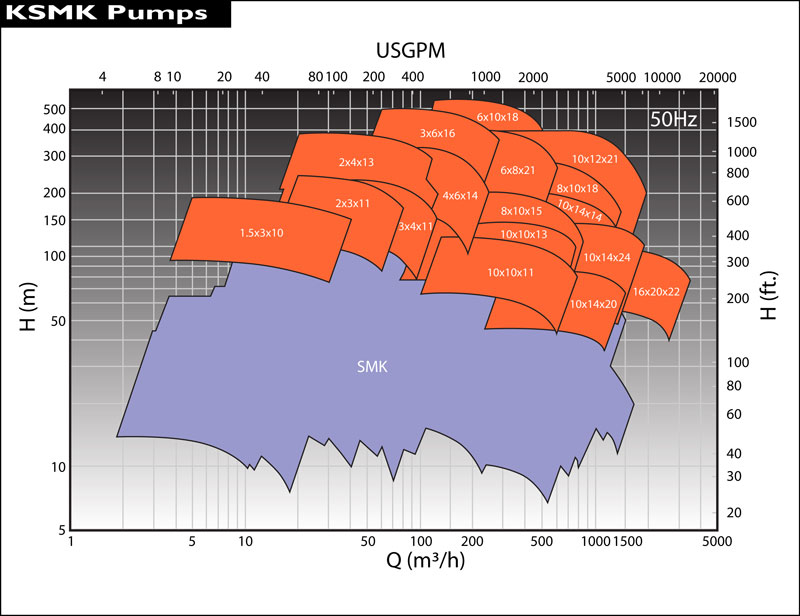

Metric 50 Hz

- Heads to 350 m

- Flows to 2,400 m3/hr

- Standards ISO 13709

- Maximum Motor Power 1,500 kW

- Temperature Range -30 to 400°C

- Maximum Case Working Pressure 60 bar

- Maximum Suction Pressure 20 bar

- Differential Head 500 m

- Maximum Viscosity Consult factory

- Mounting Configuration Horizontal/Top-Top (optional side-side)

- Seal Configurations API 682

| Part | S1 | S5 | S6 | S8 | C6 | A8 | D1 |

| Pressure Casing | Carbon Steel (A216 WCB) | 12% CHR | 316 AUS | Duplex | |||

| Impeller | Cast Iron | Carbon Steel | 12% CHR | 316 AUS | 12% CHR | 316 AUS | Duplex |

| Wear Rings | Cast Iron | 12% CHR Hardened | Hard-faced 316 AUS | 12% CHR Hardened | Hard-faced 316 AUS | Hard-faced Duplex | |

| Shaft | Carbon Steel | AISI 4140 | 316 AUS | 12% CHR | 316 AUS | Duplex | |

| Bearing Housing | Carbon Steel (A216 WCB) | ||||||

| Base Gasket | AUS, Spiral Wound | 316 AUS Spiral Wound | AUS, Spiral Wound | 316 AUS, Spiral Wound | Duplex SS Spiral Wound | ||