Designed for aggressive pump processes requiring robust casing and custom hydraulics.

Designed to heavy API-610 BB1 and ISO 13709 compliant standards for general refinery services, the PDH-LH pump features an axially split case with a single or double suction impeller, one stage of double suction and a centerline design for higher temperature services

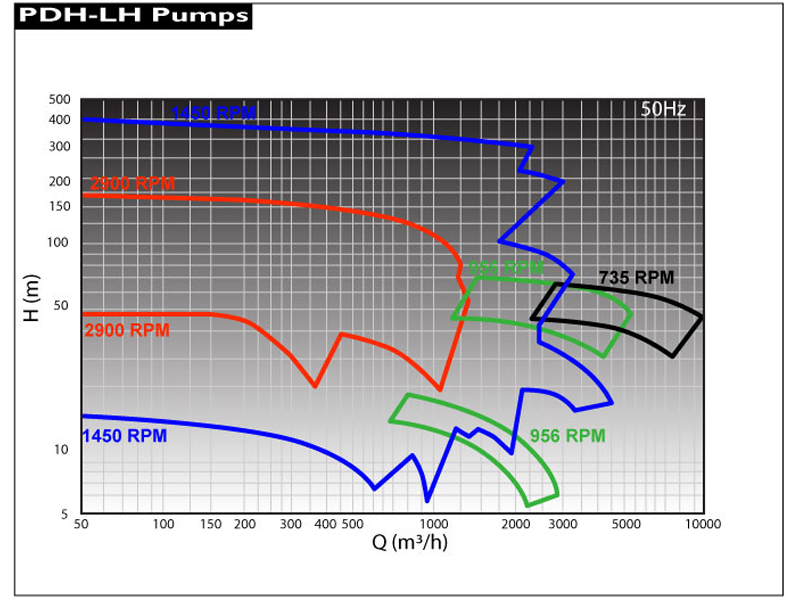

- Flows to 27,298 gpm (4,905 m³/hr)

- Heads to 600 ft (200 m)

- Suction Pressure 130 psi (9 bar)

- Temperature Range -22 to 302°F (-30 to 150°C)

These precision engineered API/ISO 13709 process pumps meet rigorous engineering requirements for medium to high flow crude oil and petroleum products, pipelines and ship loading & unloading applications.

APPLICATIONS

- Cooling water

- Distillation

- Sulfur recovery

- Loading

- Boiler feed boosting

- Crude oil pipeline

- Desalination

- Water transfer

Standard Features and Benefits

- API-610 10th Edition / ISO 13709 Full Compliance for reliability and accountability

- Suitable with 60 Hz and 50 kW motors

- Higher efficiencies due to a design with tangential discharge and a wide variety of hydraulics to match exact duty points

- Labyrinth bearing seals to avoid external contamination and maximize seal and lubrication life

- Highly maintainable and replaceable wear rings to reduce overall life cycle costs

- Mechanical seal chamber API-682 3rd Edition. Also complies to API-610 standards

- Choice of multiple impellers in each hydraulic pump casing for optimum efficiency over a wide operating range

- A variety of instrumentation options are available for monitoring all key operating perimeters (temperature, pressure, vibrations and more)

US 60 Hz

- Heads to 600 ft

- Flows to 27,298 gpm

- Standards API 610 BB1

- Maximum Motor Power 2,000 HP

- Temperature Range -22 to 302°F

- Maximum Case Working Pressure 218 psi

- Maximum Suction Pressure 130 psi

- Differential Head 525 ft

- Maximum Viscosity Consult Factory

- Mounting Configuration Horizontal side-side

- Seal Configurations Packing with optional mechanical seals

- Available Flanges PN16 FF/RF

- Suction and Discharge Size up to DN650

Metric 50 Hz

- Heads to 200 m

- Flows to 4,905 m3/hr

- Standards API 610

- Maximum Motor Power 1,500 kW

- Temperature Range -30 to 150°C

- Maximum Case Working Pressure 15 bar

- Maximum Suction Pressure 9 bar

- Differential Head 160 m

- Maximum Viscosity Consult factory

- Mounting Configuration Horizontal side-side

- Seal Configurations Packing with optional mechanical seals

- Available Flanges PN16 FF/RF

- Suction and Discharge Size up to DN650

| Part | S1 | S5 | S6 | S8 | C6 | A8 | D1 |

| Pressure Casing | Carbon Steel (A216 WCB) | 12% CHR | 316 AUS | Duplex | |||

| Impeller | Cast Iron | Carbon Steel | 12% CHR | 316 AUS | 12% CHR | 316 AUS | Duplex |

| Wear Rings | Cast Iron | 12% CHR Hardened | Hard-faced 316 AUS | 12% CHR Hardened | Hard-faced 316 AUS | Hard-faced Duplex | |

| Shaft | Carbon Steel | AISI 4140 | 316 AUS | 12% CHR | 316 AUS | Duplex | |

| Bearing Housing | Carbon Steel (A216 WCB) | ||||||

| Base Gasket | AUS, Spiral Wound | 316 AUS Spiral Wound | AUS, Spiral Wound | 316 AUS, Spiral Wound | Duplex SS Spiral Wound | ||

No available downloads