Reliable and economical, Sundyne integrally geared multi-stage compressors

Process gas compressors are the heart of the process. Their reliability directly impacts the productivity and the efficiency of the midstream, hydrocarbon processing or chemical plant.

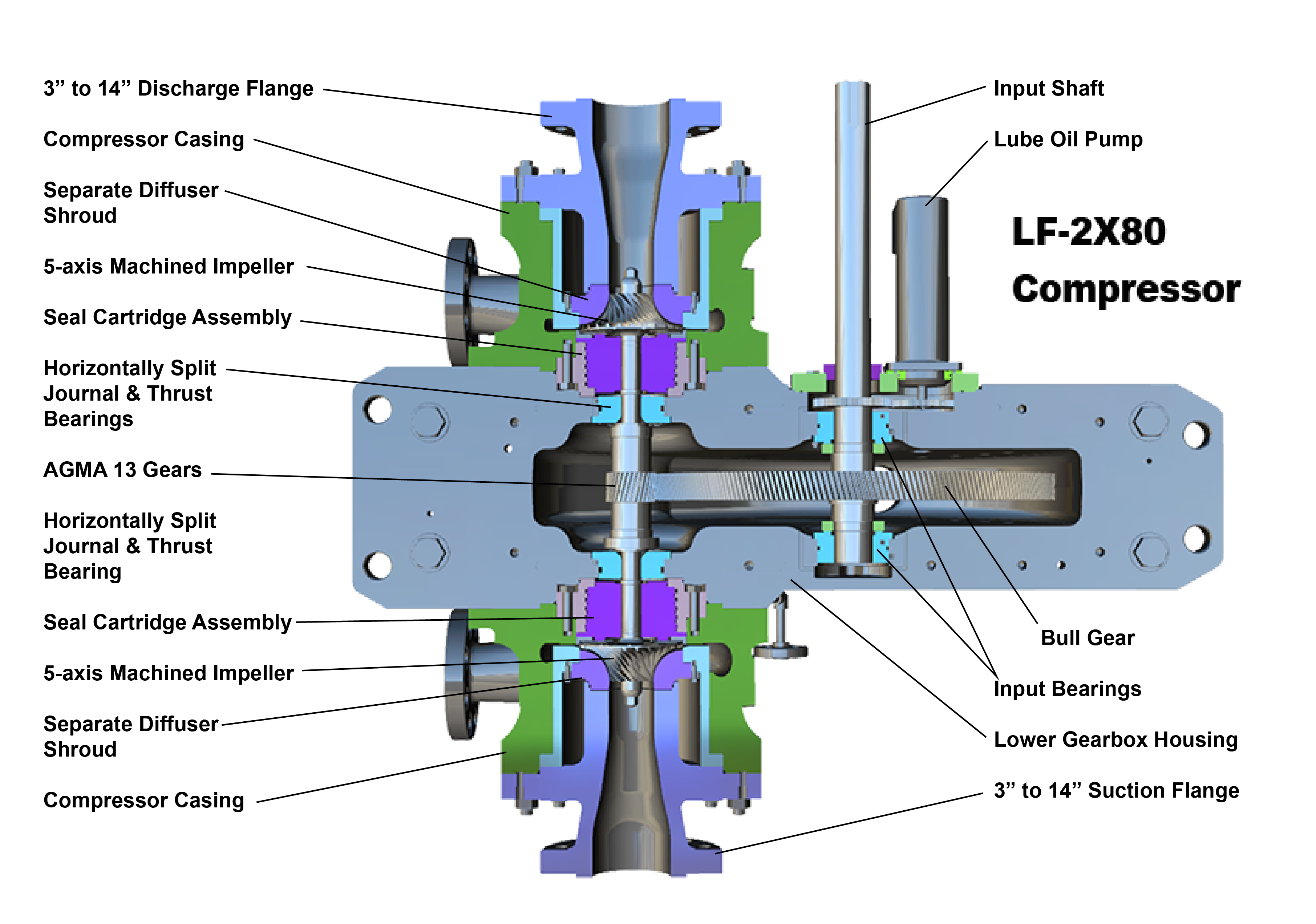

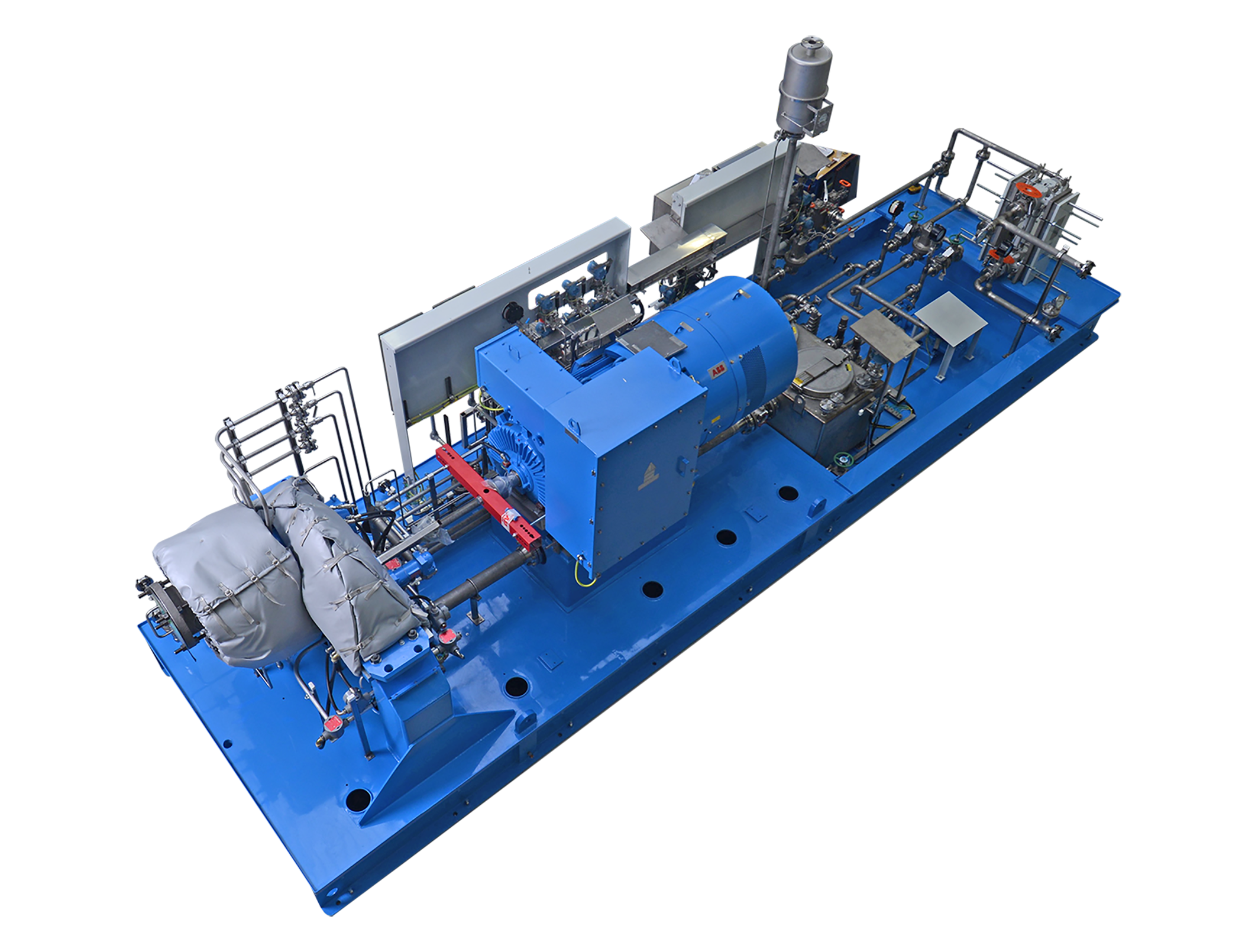

The Sundyne LF 2X80 is a compressor that can be outfitted to meet exact API and ISO standards, or it is can be economically engineered as a fit-for-purpose compressor. The 2X80 features from one to four stages of centrifugal compressors on a single gearbox. These designs save valuable space and reduces energy costs. Process engineers utilize these multi-stage compressors for midstream, hydrocarbon processing and chemical manufacturing applications including mole sieve dehydration, regeneration of the demethanizer, waste gas, hydrogen recycle and specialty chemical production. Each compressor is custom built to provide pulsation- and vibration-free operation, and to deliver oil-free process gas with zero emissions.

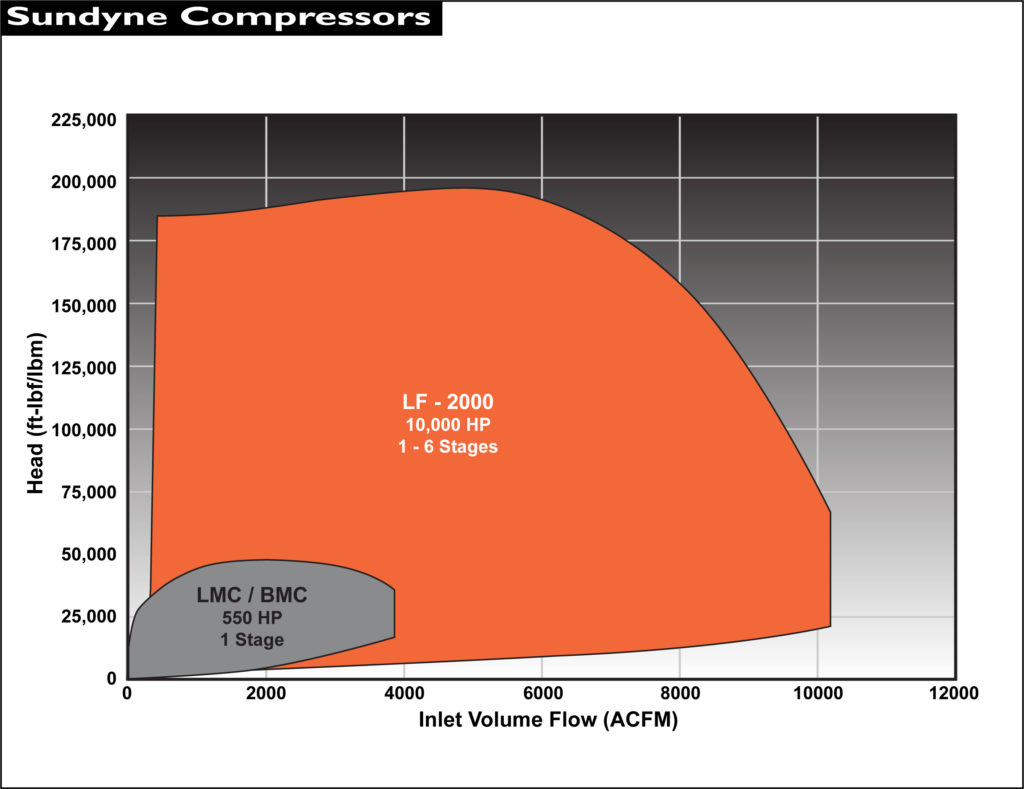

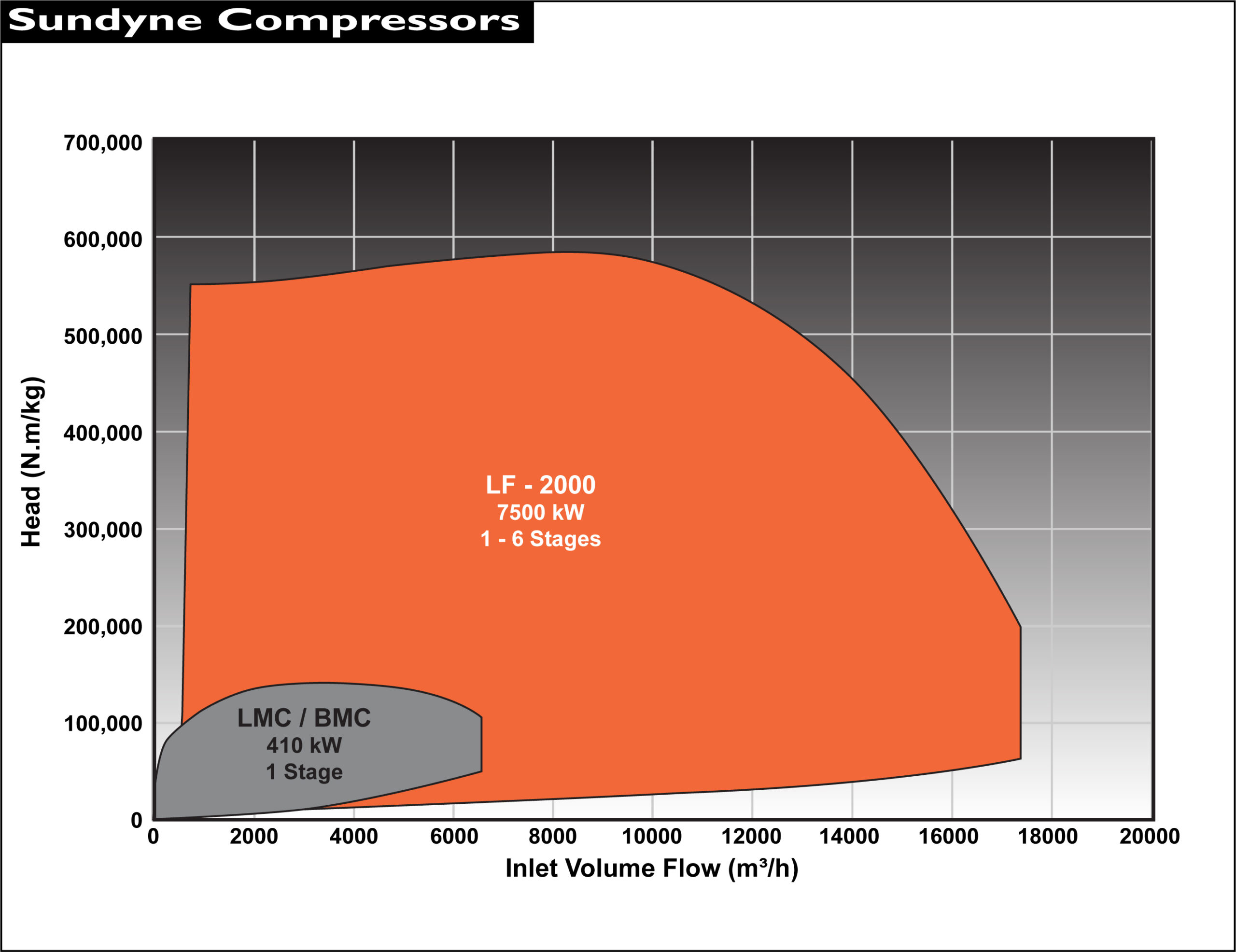

- Flows to 6,000 acfm (10,200 AM³/hr)

- Maximum working pressure 1,440 psi (100 bar)

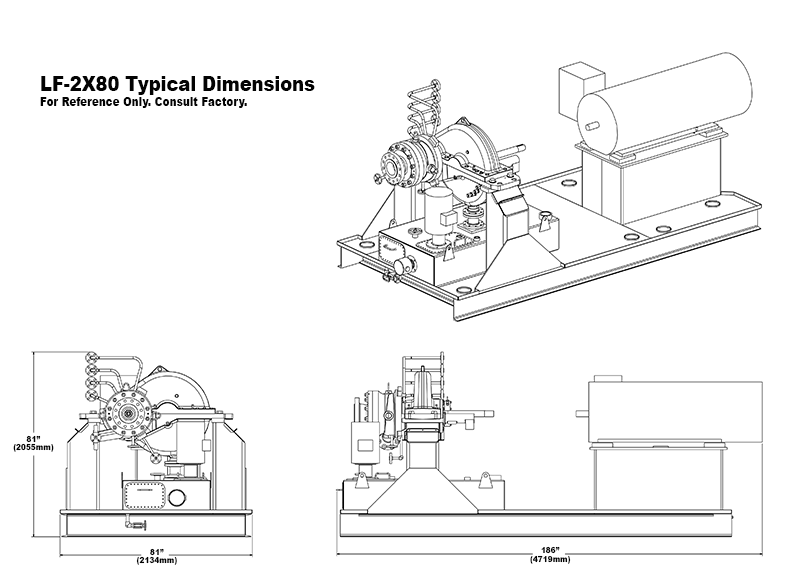

With a design heritage meeting API-617 / ISO 10439 standards, the LF 2X80 will run continuously for 5 years without costly maintenance or an overhaul. These horizontally configured compressors are ideal for skid packaging — due to their unique modular baseplate — and are easy to install into any process environment. Packaging and instrumentation are customizable to meet your needs and specifications. NACE compliant Sundyne compressors do not rust or corrode.

Sundyne gas compressors provide the performance envelope, the feature set, the reliability ratings and the uncompromising efficiency needed to address the Best Efficiency Point (BEP) for any process gas application in the most demanding environments.

APPLICATIONS

- Mole sieve dehydration

- Regeneration of the demethanizer

- Waste gas

- Hydrogen recycle

- Specialty chemical production

- Fuel gas boost for power generation

Proven to be reliable, safe, compact and efficient, the Sundyne line of integrally geared multi-stage compressors provide a number of operational benefits:

- One or two stage in-line overhung integrally geared compressor

- Single gearbox and motor saves energy and space

- Maximized up time

- Saves space-25% the size of competing reciprocating, barrel, rotary screw and diaphragm compressors

- Continuous operations for 5 years with no overhaul

- Optimized compressor engineering to meet the BEP – Best Efficiency Point to save energy through efficiency

- Smaller gearbox housing to reduce weight and cost

- Can be built as a fit-for-purpose compressor reducing instrumentation and complexity to meet customers needs

US 60 Hz

- Maximum Flow 6,000 acfm

- Maximum Speed 32,000 rpm

- Maximum Working Pressure 1,440 psi

- Temperature Range -200 to 500°F

- Maximum Motor Power 800 HP

- Hydro Test Pressure 1.5 X working pressure

- Minimum Case Thickness 1″

- Corrosion Allowance .125″

- Impeller Clearance .03″ to .05″

- Shaft Diameter at Bearings 1.5″ to 2″

- Mechanical Seal Sizes – Outboard 2.3″

- Mechanical Seal Sizes – Inboard 2.3″

- Mounting Horizontal

- Flanges 300, 600# ANSI RF Standard

- Suction Flange 4-10″

- Discharge Flange 3-10″

- Process Seals Cartridge-single, double, tandem

- Industry Standard API 617

Metric 50 Hz

- Maximum Flow 10,200 am³/hr

- Maximum Speed 32,000 rpm

- Maximum Working Pressure 100 bara

- Temperature Range -130 to 260°C

- Maximum Motor Power 596 kW

- Hydro Test Pressure 1.5 X Max working pressure

- Minimum Casing Thickness 25.4 mm

- Corrosion Allowance 3.18 mm

- Impeller Clearance .76 to 1.27 mm

- Shaft Diameter at Bearings 38.1-50.8 mm

- Mechanical Seal Sizes-Onboard 58.4 mm

- Mechanical Seal Sizes-Inboard 58.4 mm

- Mounting Horizontal

- Flanges ISO

- Suction Flange 76.2 mm

- Discharge Flange 50.8 mm

- Process Seals Cartridge-single, double, tandem

- Industry Standard ISO 10439

Gearbox Housing: Carbon Steel

High Speed Shaft with Integral Pinion: AMS 6260, 6265

Input Shaft: AISI 4340

Gears: Bull Gear – Nitrided Steel

Gears: Pinion – Carburized Steel

Low Speed Bearings: Radial Journal / Tapered Land Thrust

High Speed Bearings: Deflection Pad Journal

High Speed Bearings: Thrust – Tapered Land, Tilt-Pad, Hydrostatic

Sundyne LF 2X80 Compressor Data Sheet US – PDF

Sundyne LF 2X80 Compressor Data Sheet A4 – PDF

Sundyne Centrifugal Process Gas Compressors – Engineered For Excellence Brochure US – PDF

Sundyne Centrifugal Process Gas Compressors – Engineered for Excellence Brochure A4 – PDF

Sundyne Fit-for-Purpose Centrifugal Gas Compressors Brochure US – PDF

Sundyne Fit-for-Purpose Centrifugal Gas Compressors Brochure A4 – PDF