Reliable and economical, the original fit-for-purpose Sundyne vertical integrally geared compressor

Process gas compressors are the heart of the process. Their reliability directly impacts the productivity and the efficiency of the midstream, hydrocarbon processing or chemical plant.

The Sundyne LMC – Line Mounted Vertical Compressor line features single-stage integrally geared centrifugal designs that process engineers utilize for fit-for-purpose applications including Oil & Gas production, Bio-refinery, E-Fuels, LNG, Fuel Gas Boost Gas Treatment, Plastic production, Ammonia, Refrigeration and specialty chemical production. Each compressor is custom built to provide pulsation- and vibration-free operation, and to deliver oil-free process gas with zero emissions.

- Flows to 2,500 acfm (4,150 AM³/hr)

- Maximum working pressure 2,300 psi (160 bar)

NACE compliant Sundyne Compressors handle the most difficult gas processing conditions. Each unit is engineered in accordance with industry standards, and can be designed to run continuously for 5 years without the need for costly maintenance or over-hauls.

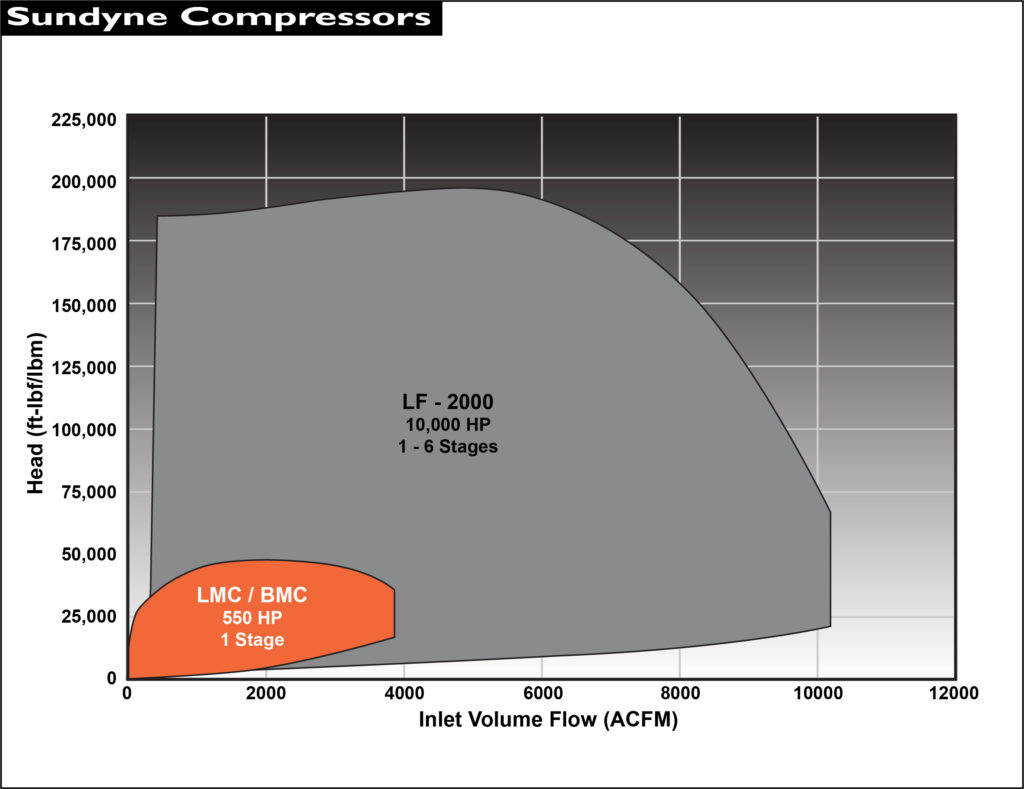

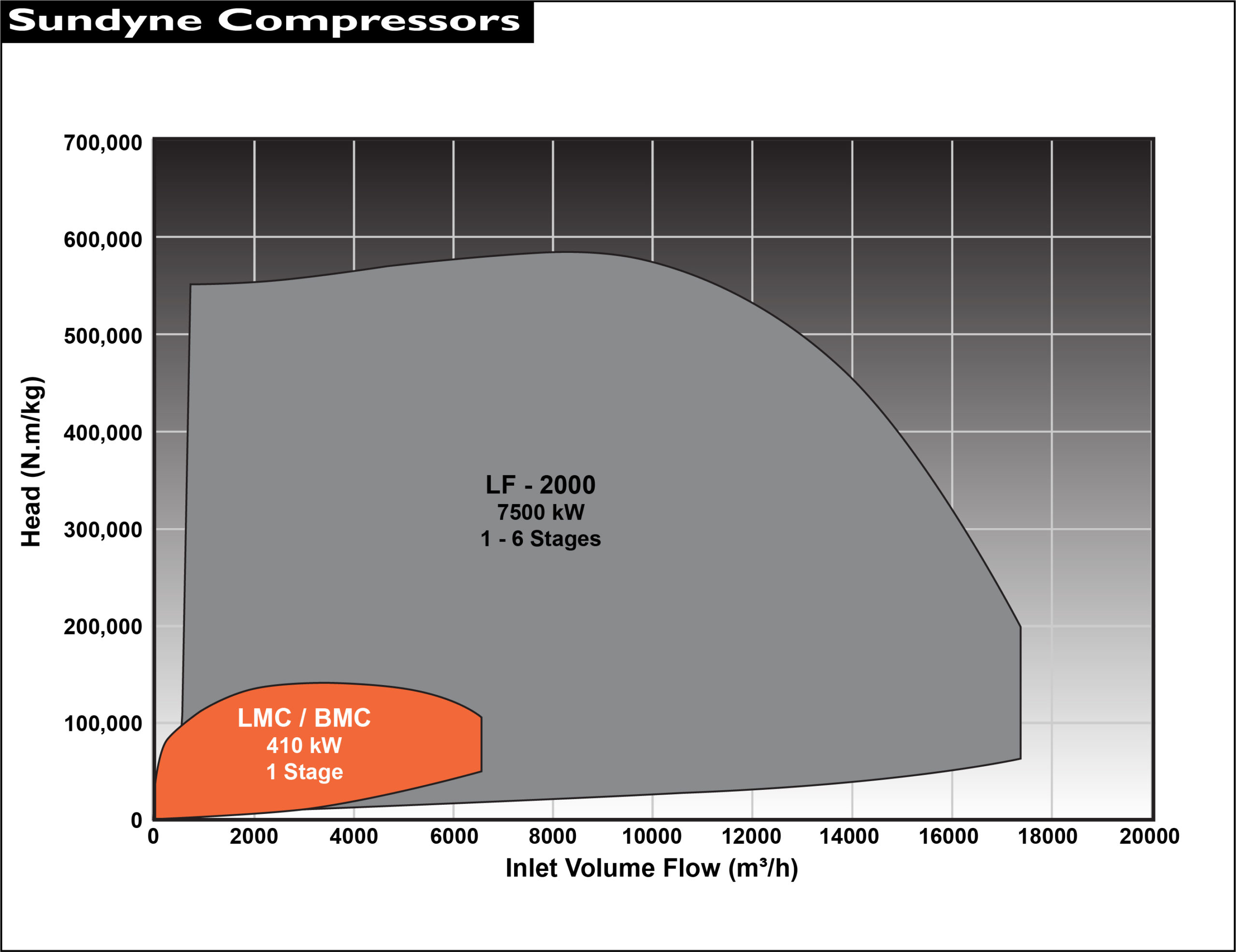

Sundyne gas compressors provide the performance envelope, the feature set, the reliability ratings and the uncompromising efficiency needed to address the Best Efficiency Point (BEP) for any process gas application.

APPLICATIONS

- Gas treatment, purification, De Oxo, Dehydration

- Overhead Gas Compression, Flash Gas Compression

- Waste Gas, Acid Gas, Wet / Dry CO2, H2S

- Feed Gas and Recycle Gas Compressor, Hydrocarbons, Hydrogen

- Ammonia, Chlorine, Ethylene, Propylene, Refrigerant Gases

Proven to be reliable, safe, compact and efficient, Sundyne LMC line of vertical integrally geared compressors provide a number of operational benefits:

- Single stage, vertical in-line overhung integrally geared compressor

- Maximized up time

- Saves space-25% the size of competing reciprocating, barrel, rotary screw compressors

- Continuous operations for 5 years with no overhaul (optional)

- Optimized compressor engineering to meet the BEP – Best Efficiency Point to save energy through efficiency

US 60 Hz

- Maximum Flow to 2,500 acfm

- Maximum Speed 34,200 rpm @ 60Hz

- Maximum Working Pressure 2,300 psi

- Temperature Range -200 to 500°F

- Maximum Motor Power 550 HP

- Mounting Vertical

- Flanges 600# ANSI RF Standard, Other Ratings Available

- Suction Flange 3″, 6″ and 8″

- Discharge Flange 2″, 4″ and 6″

- Gearbox Oil Temp Range 120 to 180°F

- Gearbox Lubricant ISO VG 32 or 46 oil

- Gearbox Lube System Pressurized

- Gears Hardened and precision ground, helical

- Input Shaft Bearings Ball or Roller

- Idler Shaft Bearings Ball or Journal

- Output Shaft Bearings Journal or Tilting Pads

- Coupling Type Non-lubricated Flexible Type

Metric 50 Hz

- Maximum Flow 4,150 am³/hr

- Maximum Speed 33,600 rpm @ 50Hz

- Maximum Working Pressure 160 bar

- Temperature Range -130 to 260°C

- Maximum Motor Power 410 kW

- Mounting Vertical

- Flanges 600# ANSI RF Standard, Other Ratings Available

- Suction Flange 3″, 6″ and 8″

- Discharge Flange 2″, 4″ and 6″

- Gearbox Oil Temp Range 120 to 180°F

- Gearbox Lubricant ISO VG 32 or 46 oil

- Gearbox Lube System Pressurized

- Gears Hardened and precision ground, helical

- Input Shaft Bearings Ball or Roller

- Idler Shaft Bearings Ball or Journal

- Output Shaft Bearings Journal or Tilting Pads

- Coupling Type Non-lubricated Flexible Type

Casing: Carbon Steel, Stainless Steel, Alloy Steel, other metallurgy on request

Impeller: Stainless Steel, Titanium, Alloy Steel, Aluminum, other metallurgy on request

Shafts: Carbon Steel, Stainless Steel, Alloy Steel

Seals: Stainless Steel, Alloy Steel, non-metallic materials

Gearbox housings: Aluminum

O-rings: As Required

Special mettalurgy is available to comply with NACE standards and any specific gas & operating conditions.

Sundyne Centrifugal Process Gas Compressors – Engineered For Excellence Brochure US – PDF

Sundyne Centrifugal Process Gas Compressors – Engineered for Excellence Brochure A4 – PDF

Sundyne Fit-for-Purpose Centrifugal Gas Compressors Brochure US – PDF

Sundyne Fit-for-Purpose Centrifugal Gas Compressors Brochure A4 – PDF