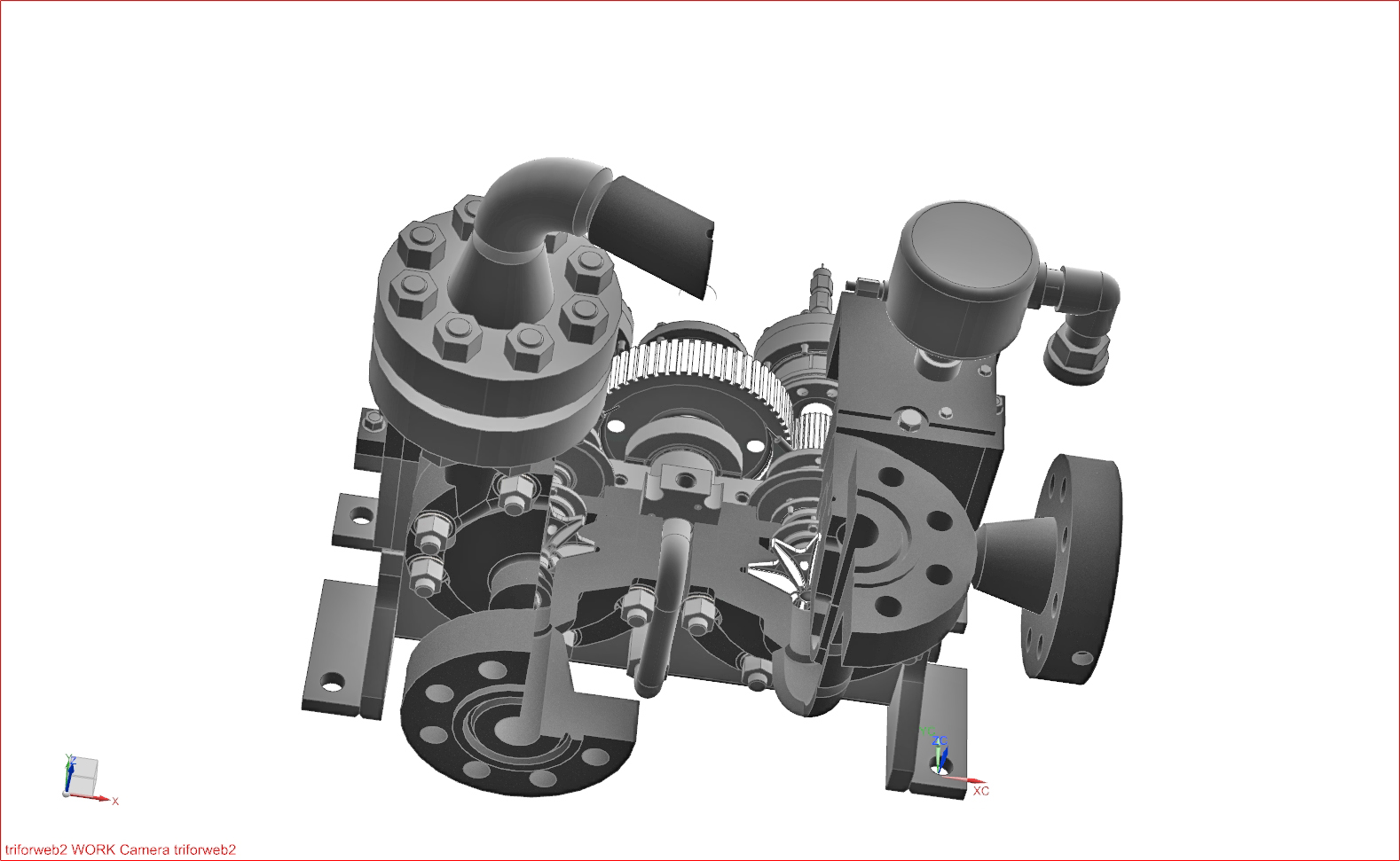

Heavy duty and extremely high pressure, the Sundyne overhung impeller integrally geared multi-stage pump

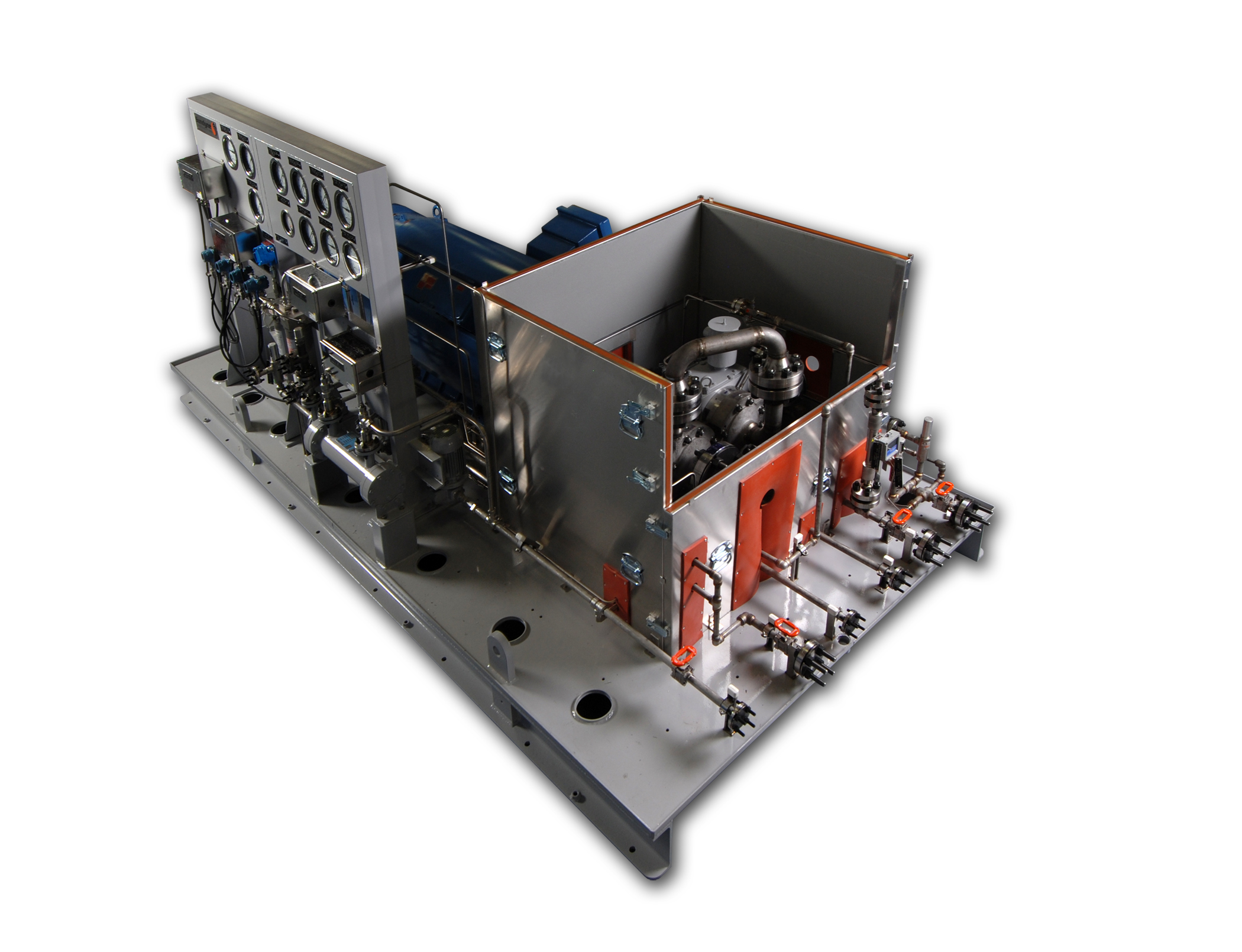

Sundyne integrally gear driven multi-stage pumps are utilized by process engineers to manufacture fertilizer, urea and PTA. These pumps are able to safely reach extremely high pressures and will run reliably for 5 years without an overhaul. Up to three pump stages are powered by a single gearbox and motor resulting in energy and space savings. Sundyne multi-stage pumps generally utilize only 25% of the space and require much less maintenance than between bearing pumps and generate extremely high pressures.

Unlike conventional multi-stage pumps, Sundyne computer tailored hydraulics place the B.E.P. (best efficiency point) at the rated point resulting in optimum efficiency. An added benefit is reduced end-of-curve horsepower, allowing for smaller driver sizes resulting in energy savings.

- Flows to 440 gpm (100 m³/hr)

- Heads to 10,000 ft (3,050 m)

- Suction Pressure 425 psi (30 bar)

- Temperature Range -200 to 500°F (-130 to 260°C)

APPLICATIONS

- Fertilizer manufacturing

- PTA – Purified Terephthalic Acid

- Urea processing

Proven to be reliable, safe, compact and efficient, Sundyne HMP 3000 OH6 integrally geared up to 3 stage pumps provide a number of operational benefits:

- Two stage overhung pump according to API 610 – ISO 13709 design recommendations for integrally geared pumps

- Maximized up time

- Saves space-25% the size of competing multi-stage pumps

- ATEX certified

- Continuous operations for 5 years with no overhaul

- Barske impeller low NPSH technology

- Optimized pump engineering to meet the BEP – Best Efficiency Point to save energy through efficiency

- Safely reaches extremely high-pressures quickly

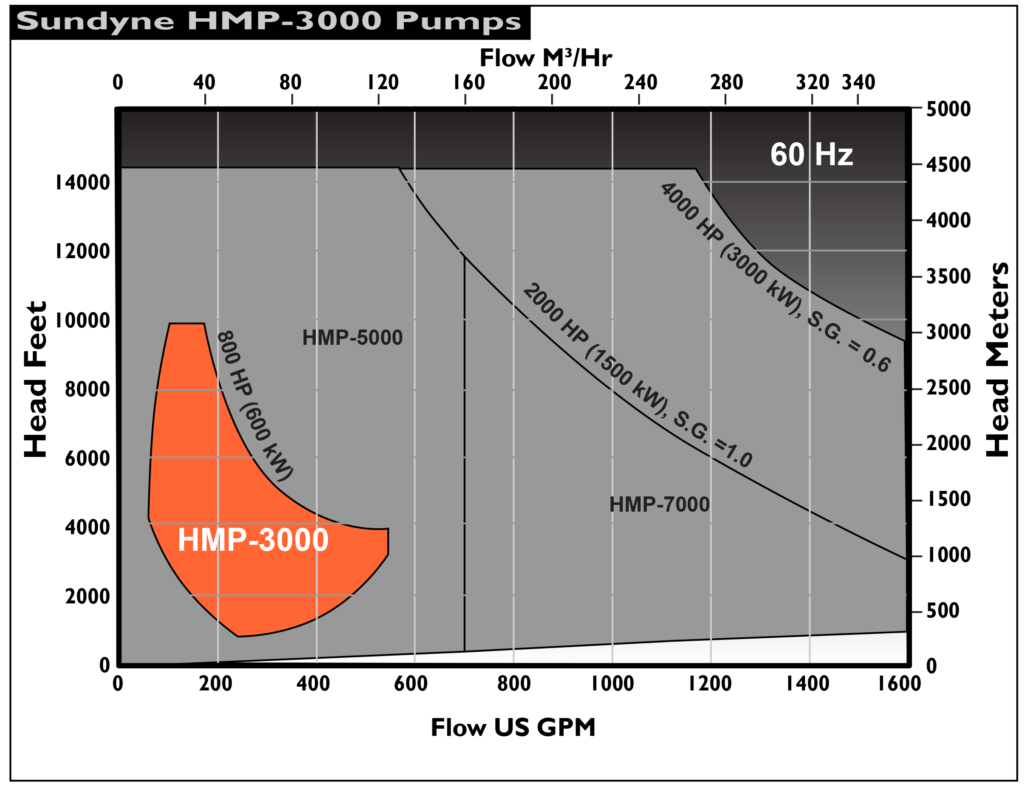

US 60 Hz

- Heads to 10,000 ft

- Flows to 440 gpm

- Standards API Style

- Number of Stages 1 or 2

- Maximum Motor Power 800 HP

- Temperature Range -200 to 500°F

- Maximum Case Working Pressure 3,750 psi

- Maximum Suction Pressure 425 psi

- Maximum Viscosity 700 cp

- Solids Range 0.015″

- Mounting Configuration Horizontal

- Seal Configurations Single, Double, Tandem

- Available Inducer Yes

- Available Flanges 600#, 900#, 1500# RF or RTJ

- Suction and Discharge Sizes 4″ x 3″

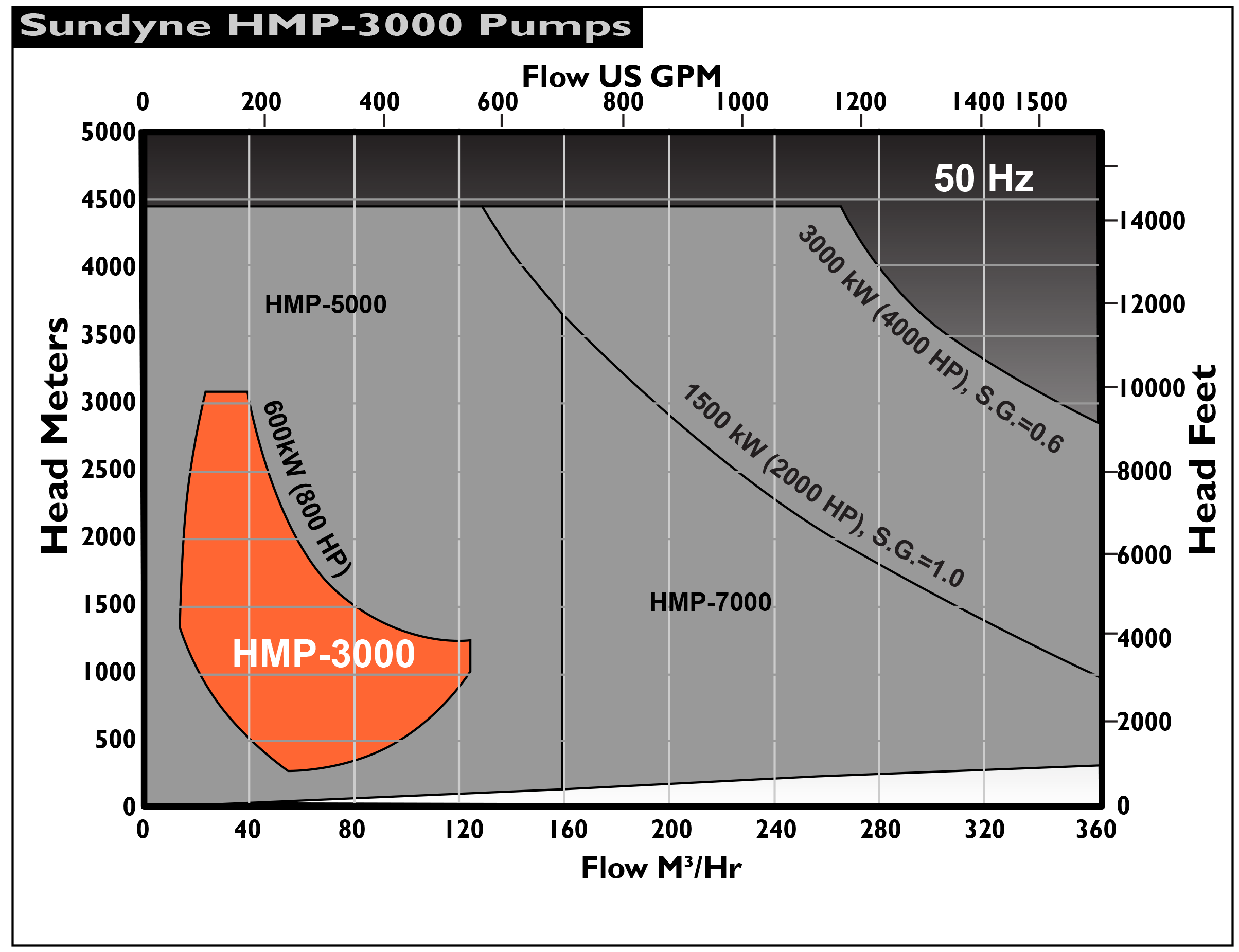

Metric 50 Hz

- Heads to 3,050 m

- Flows to 100 m3/hr

- Standards ISO Style

- Number of Stages 1 or 2

- Maximum Motor Power 600 kW

- Temperature Range -130 to 260°C

- Maximum Case Working Pressure 260 bar

- Maximum Suction Pressure 30 bar

- Maximum Viscosity 700 cp

- Solids Range 400 microns

- Mounting Configuration Horizontal

- Seal Configurations Single, Double, Tandem

- Available Inducer Yes

- Available Flanges 600#, 900#, 1500# RF or RTJ

- Suction and Discharge Sizes 4″ x 3″